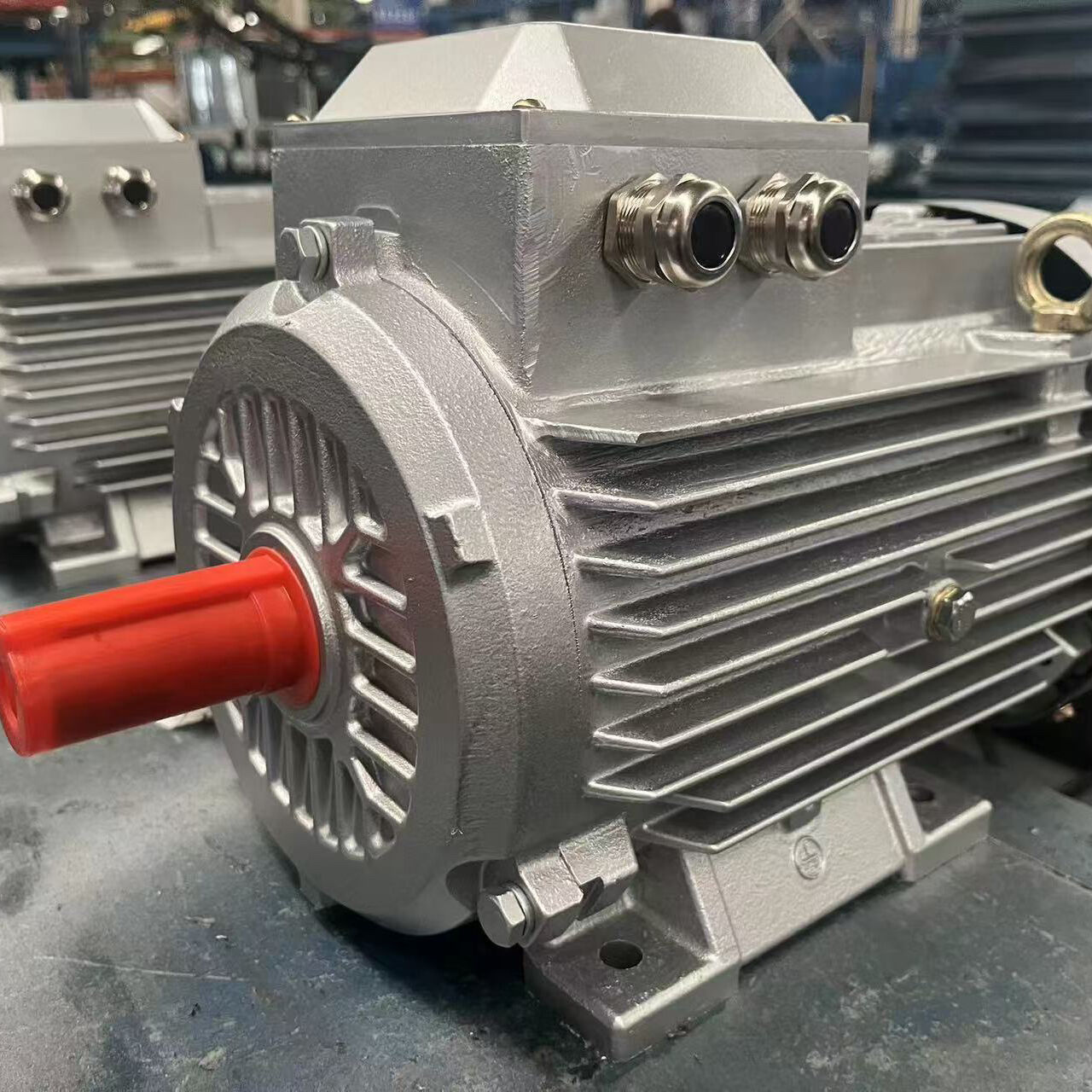

electric motor reducer

An electric motor reducer is a sophisticated mechanical device that combines an electric motor with a gear reduction system to optimize power transmission and motion control. This essential component effectively transforms the high-speed, low-torque output of an electric motor into a more manageable low-speed, high-torque performance. The system operates through a series of precisely engineered gears that work in harmony to achieve the desired speed reduction while maintaining optimal efficiency. The reducer's design incorporates advanced materials and precision engineering to ensure durability and reliable performance across various applications. It features multiple gear stages that can be configured to achieve specific reduction ratios, making it highly adaptable to different industrial requirements. The unit's compact design integrates seamlessly with existing machinery while providing robust power transmission capabilities. Modern electric motor reducers often include enhanced cooling systems, specialized lubrication methods, and advanced sealing technologies to ensure consistent performance and extended service life. These devices are fundamental in numerous industrial applications, from manufacturing and processing equipment to conveyor systems and heavy machinery, where precise speed control and high torque are essential for operational success.