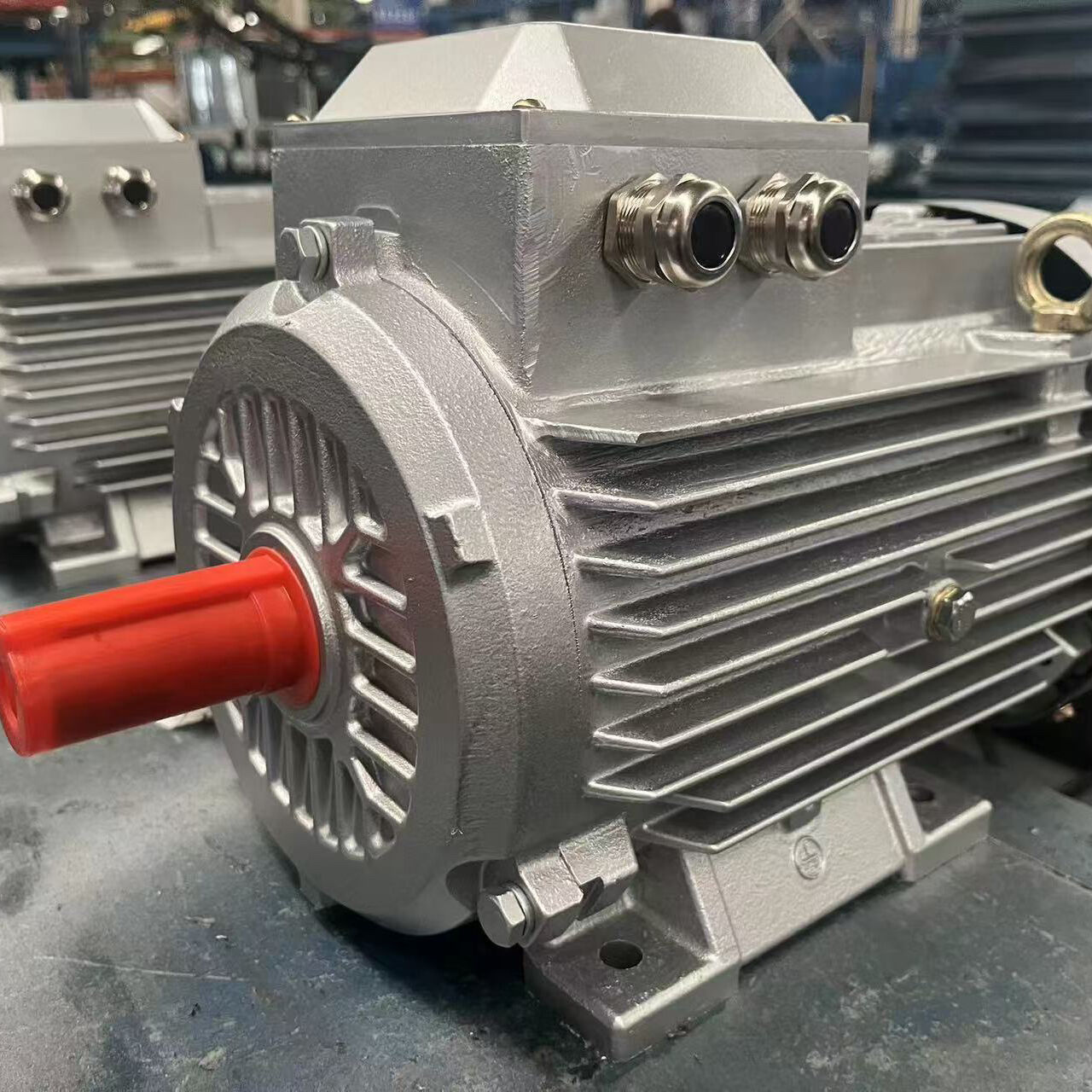

gearbox reducer for electric motor

A gearbox reducer for electric motor is a crucial mechanical component that optimizes motor performance by effectively managing speed and torque output. This sophisticated device consists of a series of precision-engineered gears housed within a durable casing, designed to reduce the motor's speed while simultaneously increasing its torque capacity. The primary function involves converting high-speed, low-torque rotation into lower-speed, higher-torque output, making it essential for various industrial applications. The reducer employs multiple gear stages, typically utilizing helical or spur gears, to achieve the desired ratio reduction. These components work in harmony to ensure smooth power transmission while minimizing energy loss and mechanical wear. Modern gearbox reducers incorporate advanced features such as efficient lubrication systems, thermal management capabilities, and robust sealing mechanisms to ensure reliable operation in demanding environments. They are particularly valuable in applications requiring precise speed control, such as conveyor systems, packaging machinery, and heavy industrial equipment. The design considerations include factors like mounting orientation, environmental conditions, and specific load requirements, making them highly adaptable to diverse operational needs.