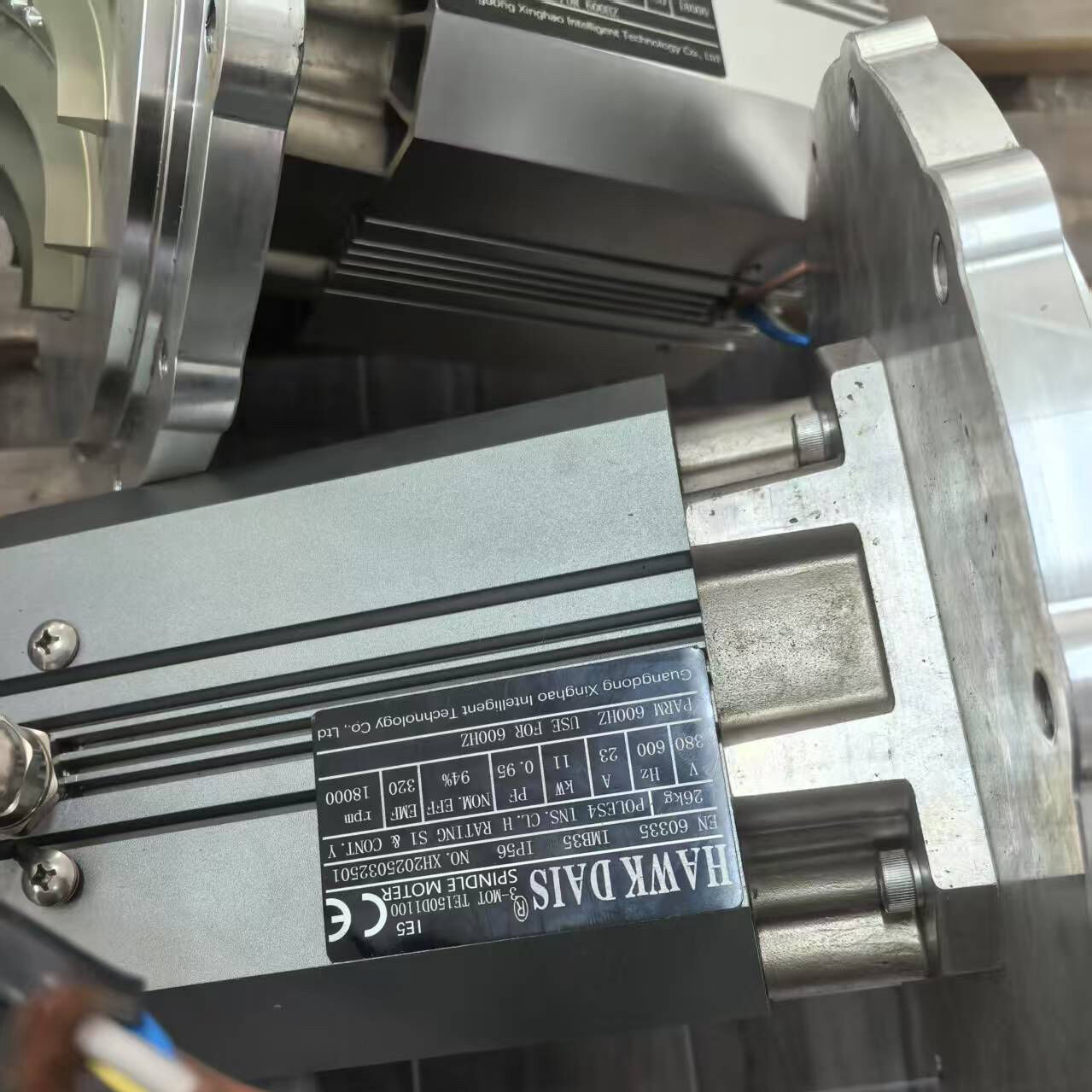

high speed electric motor

High speed electric motors represent a cutting-edge advancement in motor technology, operating at rotational speeds significantly higher than conventional motors, typically ranging from 10,000 to over 100,000 RPM. These sophisticated machines convert electrical energy into mechanical energy with remarkable efficiency, utilizing advanced bearing systems and precise rotor dynamics to maintain stability at extreme speeds. The motor's design incorporates specialized materials and construction techniques to withstand the intense forces generated during high-speed operation, including reinforced shaft assemblies and optimized cooling systems. These motors excel in applications requiring precise control and exceptional performance, such as industrial machinery, aerospace equipment, and advanced manufacturing processes. The integration of modern power electronics and control systems enables precise speed regulation and torque control, making these motors ideal for demanding applications where traditional motors fall short. Their compact size relative to their power output makes them particularly valuable in space-constrained installations, while their superior energy efficiency contributes to reduced operational costs and environmental impact.