Understanding Electric Motor Types for Everyday Applications

Electric motors power countless devices and machines in our daily lives, from household appliances to workshop equipment. When selecting the right motor for small tasks, the choice between single phase and three phase motors becomes crucial for optimal performance and efficiency. This comprehensive guide explores the key differences, applications, and practical considerations between these two motor types to help you make an informed decision.

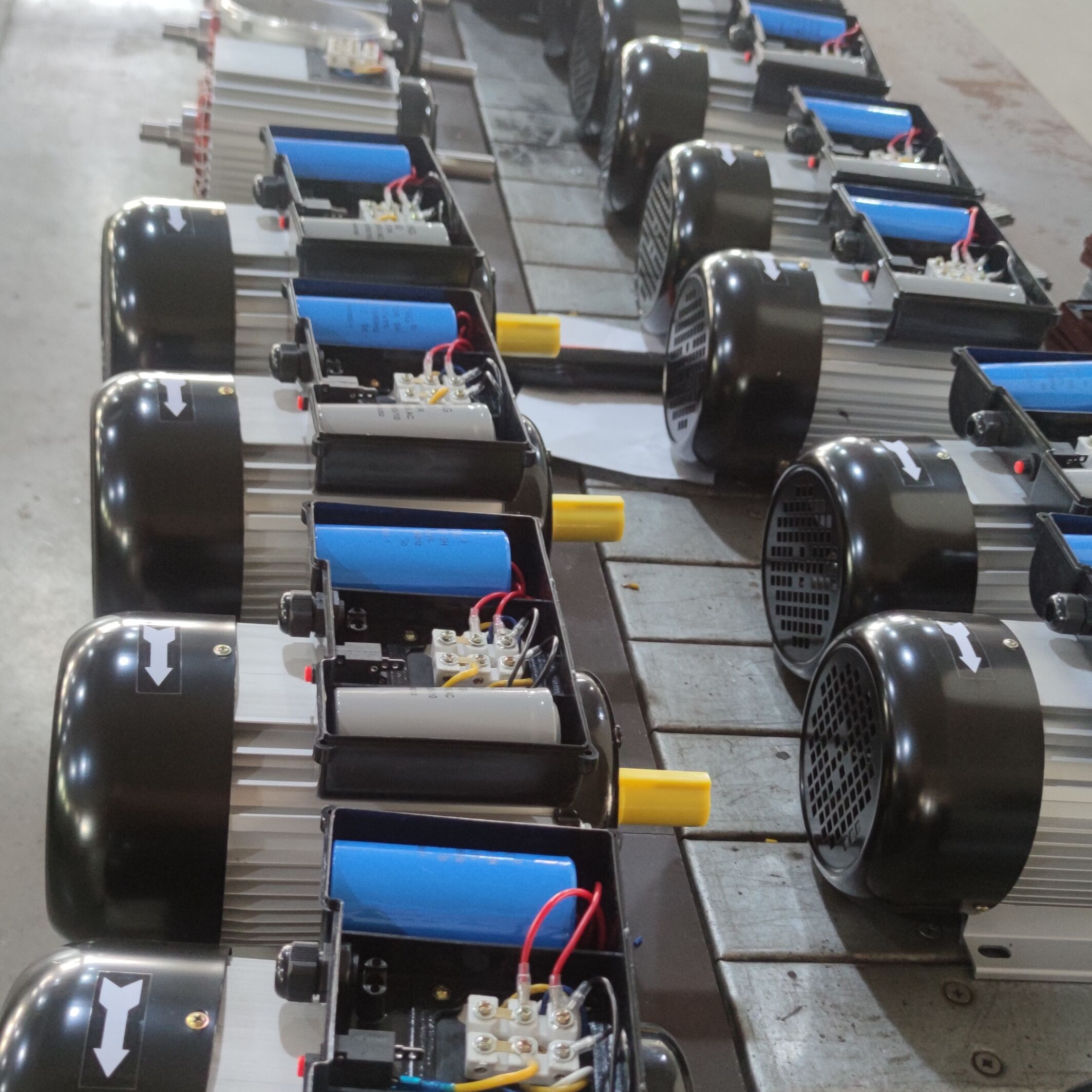

Fundamental Differences Between Single and Three Phase Motors

Power Supply and Wiring Configuration

Single phase motors operate on a standard residential power supply, utilizing one power wire and one neutral wire. This simple configuration makes them readily compatible with most household electrical systems. The power delivery occurs in a single alternating wave pattern, which influences their starting characteristics and overall performance.

Three phase motors, in contrast, require three separate power lines, each carrying an alternating current that peaks at different times. This creates a more balanced and efficient power delivery system, though it typically requires specialized industrial electrical installations. The more complex wiring setup contributes to their higher initial installation costs but offers superior performance benefits.

Starting Mechanism and Torque Delivery

Single phase motors need additional starting mechanisms since they cannot self-start from a standstill position. Common solutions include capacitor-start, split-phase, or shaded-pole configurations. These starting methods, while effective, can result in lower initial torque compared to their three phase counterparts.

Three phase motors provide inherently smooth starting characteristics and consistent torque delivery throughout their operation. The balanced power input creates a rotating magnetic field naturally, eliminating the need for auxiliary starting components. This advantage makes them particularly suitable for applications requiring frequent starts or consistent torque under varying loads.

Performance Characteristics in Small Task Applications

Efficiency and Power Output

In small task applications, single phase motors typically operate at lower efficiency levels compared to three phase motors. This efficiency gap becomes more pronounced under partial load conditions, where single phase motors may consume more energy to maintain the same output. However, for many household and light commercial applications, this efficiency difference may not significantly impact operating costs.

Three phase motors maintain higher efficiency levels across their operating range, converting more electrical energy into mechanical power. Even in smaller sizes, they demonstrate superior performance in terms of power factor and energy consumption. This advantage must be weighed against the higher initial costs and installation requirements.

Speed Control and Operation Stability

Single phase motors generally offer limited speed control options without specialized electronic controllers. Their speed tends to remain relatively constant under normal operating conditions, which can be advantageous in applications requiring steady speeds. However, they may experience more speed fluctuation under varying loads.

Three phase motors provide better speed regulation and can be more easily controlled using variable frequency drives (VFDs). This flexibility makes them suitable for applications requiring precise speed control, even in smaller power ratings. The inherent stability of three phase power also results in smoother operation and reduced vibration.

Cost Considerations and Installation Requirements

Initial Investment and Setup Costs

Single phase motors typically present lower upfront costs, making them an attractive option for small tasks and residential applications. Their simpler construction and widespread availability contribute to more affordable purchase prices. Installation costs remain minimal due to their compatibility with standard electrical systems.

Three phase motors generally require higher initial investment, not only for the motor itself but also for the necessary electrical infrastructure. Small businesses and workshops considering three phase motors must factor in potential electrical system upgrades and installation costs. However, their longer lifespan and better efficiency can offset these initial expenses over time.

Maintenance and Operating Expenses

Single phase motors may require more frequent maintenance due to their additional starting components and higher operating temperatures. The wear on starting capacitors and centrifugal switches can lead to increased maintenance costs over time. However, repairs are generally straightforward and can be performed by most qualified electricians.

Three phase motors typically exhibit lower maintenance requirements due to their simpler mechanical construction and more balanced operation. The absence of starting components reduces potential failure points, contributing to longer service intervals and lower long-term maintenance costs. Their superior efficiency also results in lower operating expenses through reduced energy consumption.

Frequently Asked Questions

Can I convert a single phase motor to three phase operation?

While it's technically possible to use phase converters or VFDs to run three phase motors on single phase power, it's generally not practical or cost-effective to convert a single phase motor to three phase operation. The motor's fundamental design and construction determine its phase requirements.

Which motor type is better for home workshop tools?

For most home workshop applications, single phase motors are the more practical choice due to their compatibility with residential power supplies and lower initial costs. However, if your workshop requires precise speed control or handles heavy-duty operations, investing in three phase power infrastructure might be worthwhile.

How do energy savings compare between the two motor types?

Three phase motors typically offer 2-4% higher efficiency compared to similar-sized single phase motors. While this difference may seem small, it can result in significant energy savings over time, especially in applications with frequent or continuous operation. The actual savings depend on usage patterns, local electricity rates, and motor loading conditions.