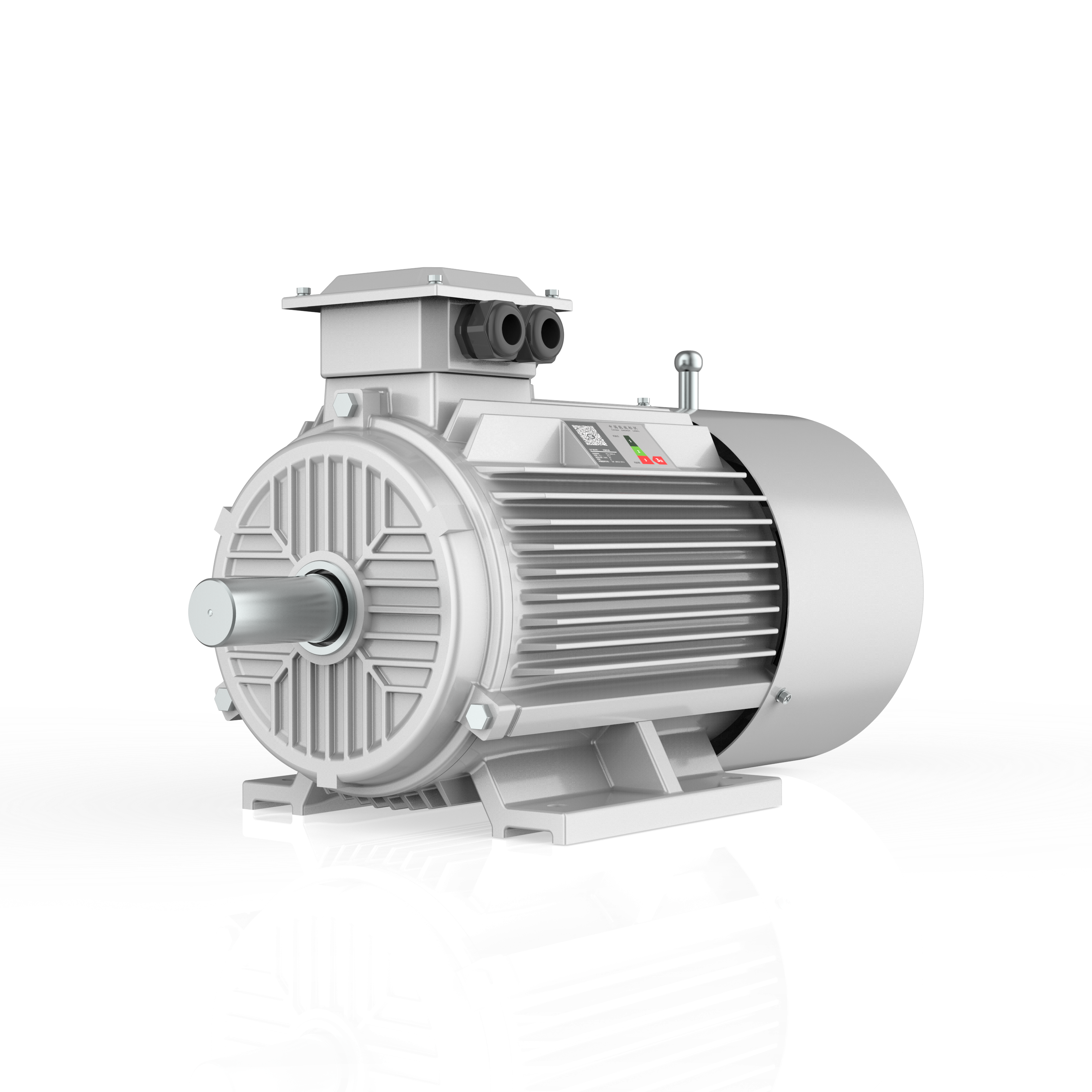

pmsm سرعت بالا

موتور همگام دائمی با سرعت بالا (PMSM) نماینده یک پیشرفت برجسته در فناوری موتورهای الکتریکی است که عملکرد برتر و کارایی فوق العاده را ترکیب میکند. طراحی نوآورانه این موتور به سرعتهای چرخشی بیش از ۱۰,۰۰۰ دور در دقیقه رسیده، که آن را مناسب جهت کاربردهای صنعتی چالشبرانگیز میسازد. PMSM از مغناطیسهای دائمی قرار داده شده در inside_rotor استفاده میکند تا میدان مغناطیسی ثابتی ایجاد کند، که این موضوع کنترل دقیق سرعت و خروجی گشتاور بهینه را ممکن میسازد. طراحی پیشرفته آن از مواد مغناطیسی پیشرفته و مهندسی دقیق استفاده میکند تا پایداری را در سرعتهای بالا حفظ کرده و از کاهش ضایعات انرژی جلوگیری کند. ساختار فشرده موتور اجازه نصب آن را در محیطهای محدود فضا میدهد، اما قدرت چگالی عالی ارائه میدهد. در کاربردهای صنعتی، این موتورها در ماشینکاری با سرعت بالا، فشاردهای سنتریفیژ و پمپهای توربو moleculer بهترین عملکرد را نشان میدهند. ادغام سیستمهای کنترل مدرن نظارت و تنظیم واقعی-زمانی پارامترهای موتور را فراهم میکند، که اطمینان از عملکرد بهینه تحت شرایط بارگذاری مختلف را تضمین میکند. با توجه به توانایی حفظ کارایی بالا در دامنه سرعت گستردهای، این موتورها در بخشهای فضایی، خودرو و تولید صنعتی پیشرفته به طور فزایندهای محبوب شدهاند.