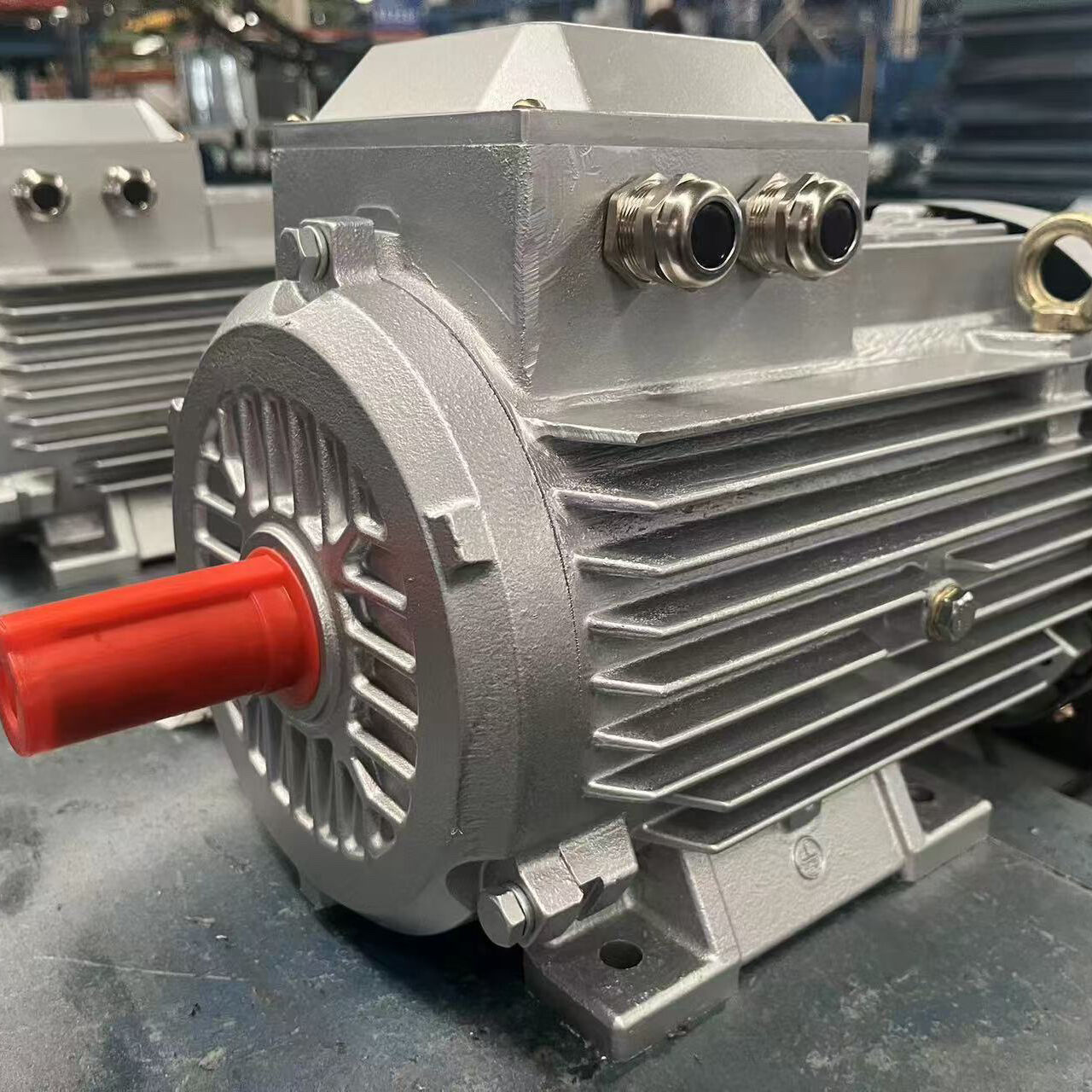

motor ijetor sinkron

Motori elektrik sinkron është një pjesë e sofistikuar makinerie elektrike që funksionon duke mbajtur sinkronizim të përsosur midis rrotullimit të boshtit të tij dhe frekuencës së rrymës elektrike që e fuqizon atë. Kjo precizion në funksionim e bën atë një komponent të pacenueshëm në aplikime të ndryshme industriale dhe komerciale. Motori përbëhet nga një stator që krijon një fushë magnetike rrotulluese dhe një rotor që rrotullohet me të njëjtën shpejtësi si fusha magnetike, kështu termi sinkron. Ajo që veçon këtë motor është aftësia e tij për të mbajtur shpejtësi konstante pavarësisht nga ndryshimet e ngarkesës, duke e bërë atë ideal për aplikime që kërkojnë kontroll të saktë të shpejtësisë. Teknologjia pas motorëve sinkron ka evoluar në mënyrë të konsiderueshme, duke përfshirë materiale të avancuara dhe sisteme digitale kontrolli që e përmisin efikasitetin dhe besueshmërinë e tyre. Këta motorë dallohen në aplikime me fuqi të lartë, zakonisht në intervalin nga disa qindra deri në mijëra kuçë fuqi, dhe gjenden zakonisht në kompresorë industriale, pompa, transportues dhe gjeneratorë. Motorët modernë sinkronë kanë shpesh eletronikë të sofistikuar për fuqizim që lejon nisje të butë dhe operim me shpejtësi variabël, duke zgjeruar dobësinë e tyre nëpër industrie të ndryshme. Dizajni i tyre lejon gjithashtu operimin me faktorë të fuqisë së përparë, i cili mund të ndihmojë në përmirësimin e efikasitetit të përgjithshëm të sistemit të energjisë dhe uljen e kostove elektrike në ambientet industriale të mëdha.