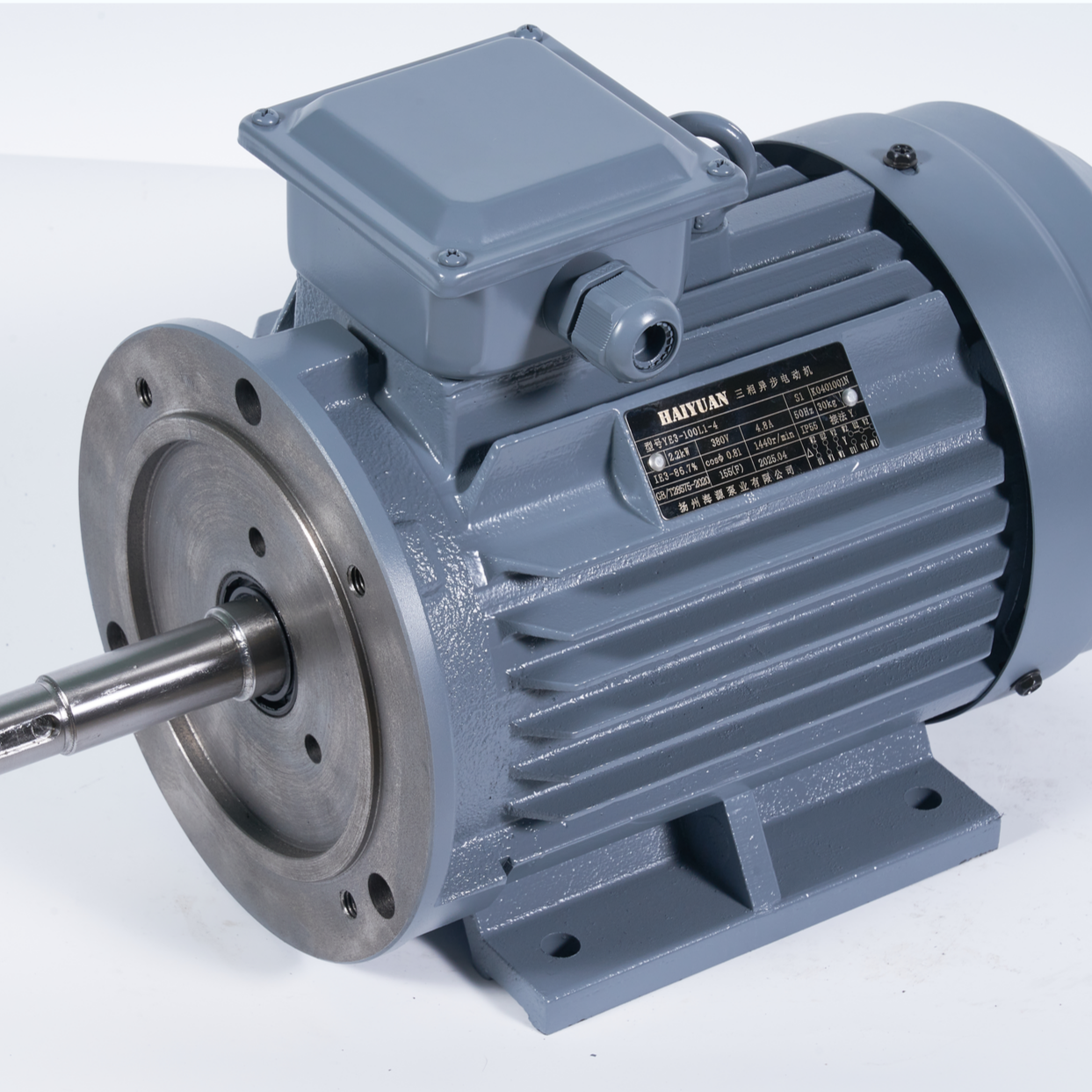

ประสิทธิภาพการใช้พลังงานและการดำเนินงานที่คุ้มค่า

ลักษณะที่โดดเด่นของมอเตอร์ลดความเร็ว คือประสิทธิภาพพลังงานที่พิเศษและการทํางานที่มีประหยัด การออกแบบที่บูรณาการทําให้การส่งพลังงานดีที่สุด โดยการลดการสูญเสียพลังงานที่มักเกี่ยวข้องกับการรวมมอเตอร์และเครื่องลดแยกกัน ระบบเกียร์ประสิทธิภาพสูง ลดการใช้พลังงานในขณะที่รักษาผลงานที่ดีที่สุด ส่งผลให้เกิดการประหยัดพลังงานที่สําคัญตลอดอายุการใช้งานของอุปกรณ์ มอเตอร์ถูกออกแบบให้ทํางานได้อย่างมีประสิทธิภาพสูงสุดในช่วงความเร็วของพวกเขา, การรับประกันการใช้พลังงานที่คงที่ไม่ว่าสภาพภาระ ประสิทธิภาพพลังงานนี้แปลโดยตรงไปสู่ค่าใช้จ่ายในการดําเนินงานที่ต่ํากว่าและการลดผลกระทบต่อสิ่งแวดล้อม ทําให้มอเตอร์ลดความร้อนเป็นทางเลือกที่มีความรับผิดชอบต่อสิ่งแวดล้อมสําหรับการใช้งานอุตสาหกรรม