hv motors

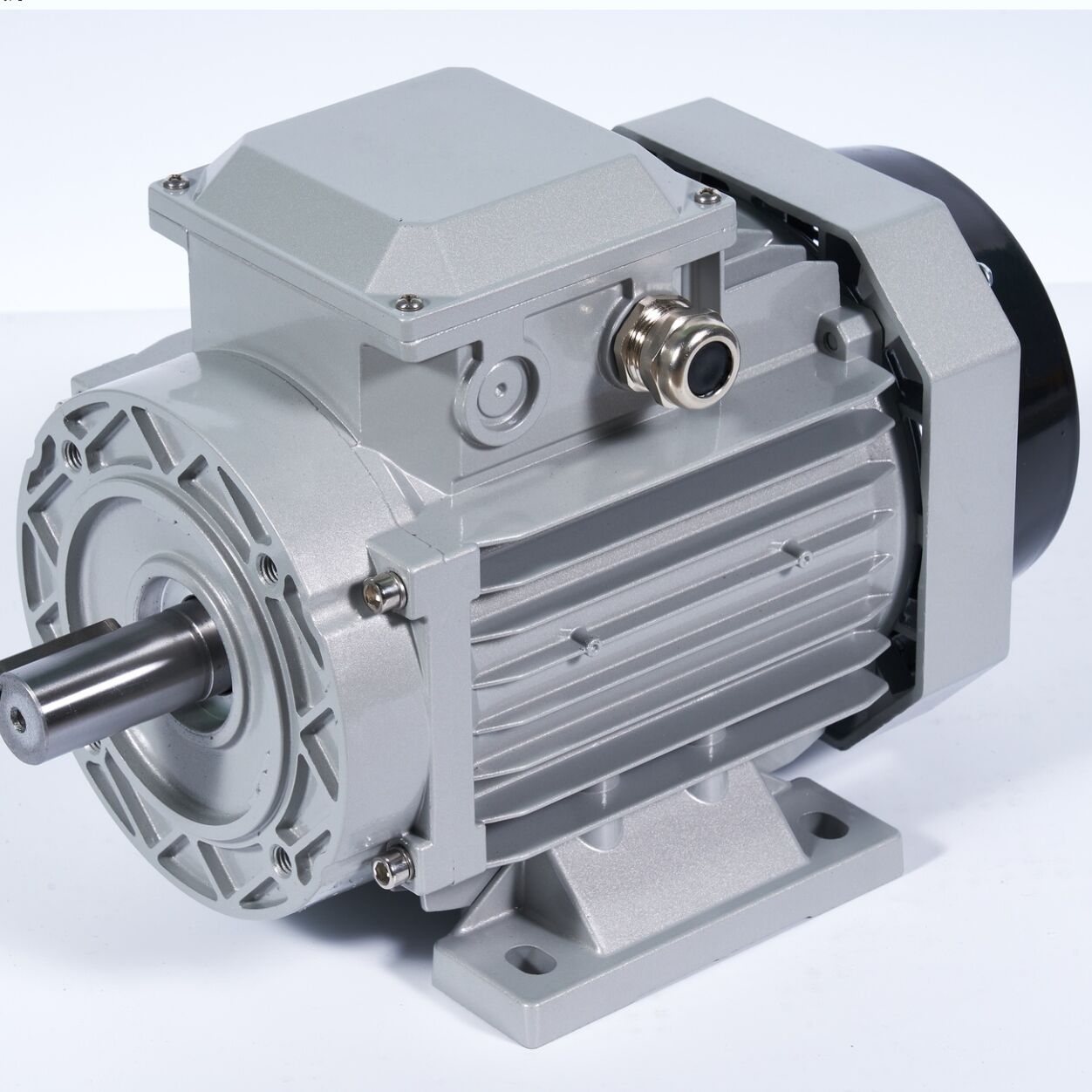

HV motors, or high voltage motors, represent a critical component in industrial power systems, designed to operate at voltage levels exceeding 1000V. These sophisticated machines convert electrical energy into mechanical energy, delivering exceptional performance for large-scale industrial applications. The motors feature robust construction with advanced insulation systems, specially engineered bearings, and precision-manufactured components that ensure reliable operation under demanding conditions. Their design incorporates multiple technological innovations, including advanced cooling systems, optimized rotor dynamics, and sophisticated control mechanisms that enable precise speed regulation and torque control. HV motors find extensive applications across various industries, including power generation, oil and gas, mining, and heavy manufacturing. They excel in driving critical equipment such as compressors, pumps, fans, and mill drives, where high power output and operational reliability are paramount. These motors are equipped with comprehensive monitoring systems that track performance parameters, allowing for predictive maintenance and optimal operational efficiency. Their robust construction ensures extended service life, while their energy-efficient design helps organizations reduce operational costs and environmental impact.