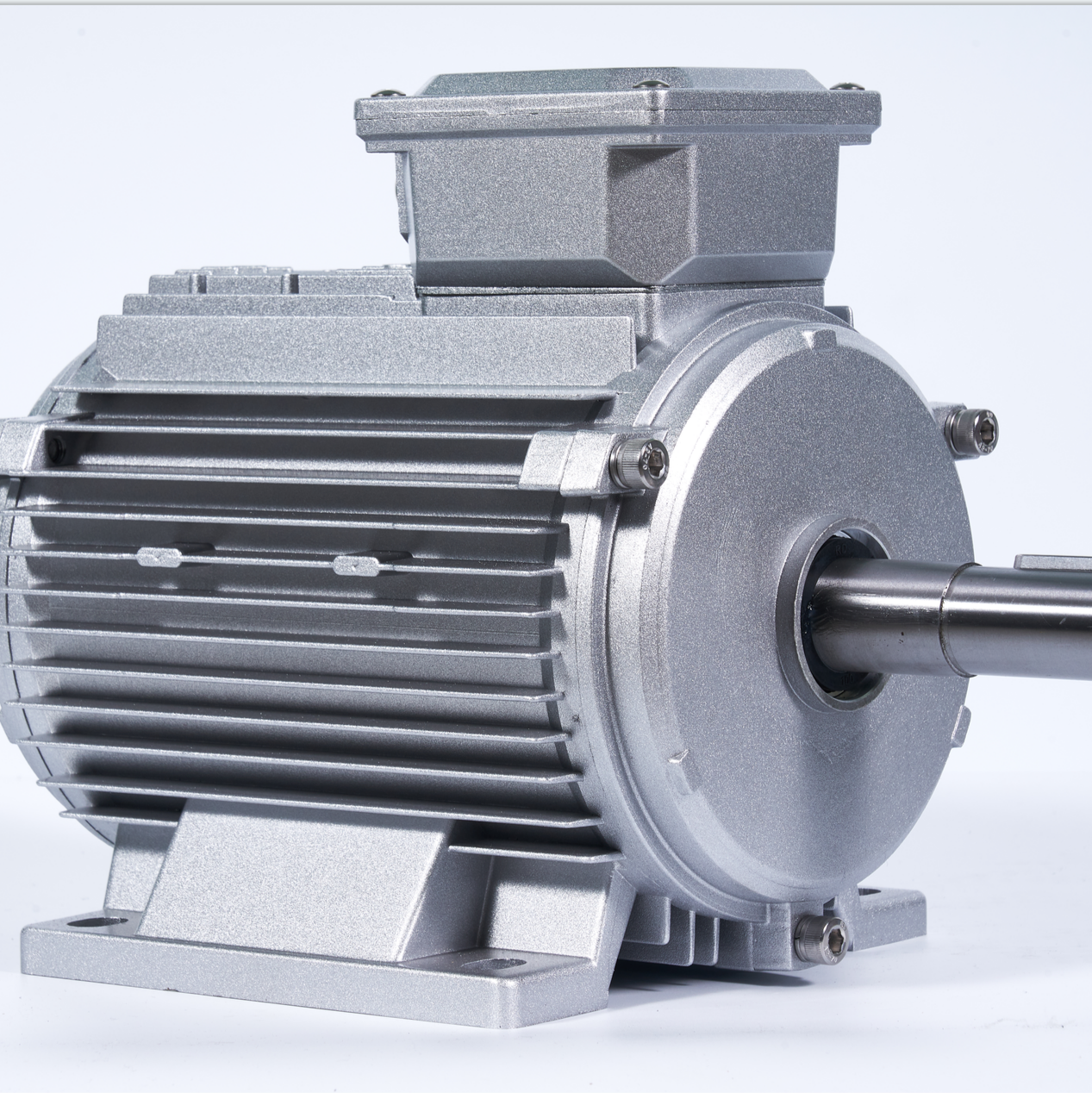

integrated servo motor

An integrated servo motor represents a groundbreaking advancement in motion control technology, combining a servo motor, drive, and controller into a single, compact unit. This all-in-one design eliminates the need for external drive cabinets and complex wiring systems, resulting in a more streamlined and efficient solution. The integrated servo motor incorporates advanced feedback systems, precise position control, and sophisticated motion algorithms to deliver exceptional performance across various applications. The unit features built-in thermal management systems, intelligent communication protocols, and real-time monitoring capabilities, ensuring optimal operation and maintenance. These motors excel in applications requiring precise motion control, from automated manufacturing and packaging systems to robotics and CNC machinery. The integration of all components reduces installation time, minimizes potential points of failure, and creates a more reliable system overall. With features like self-diagnostics, programmable motion profiles, and seamless network connectivity, integrated servo motors represent the future of industrial automation, offering unprecedented levels of control and efficiency in a compact form factor.