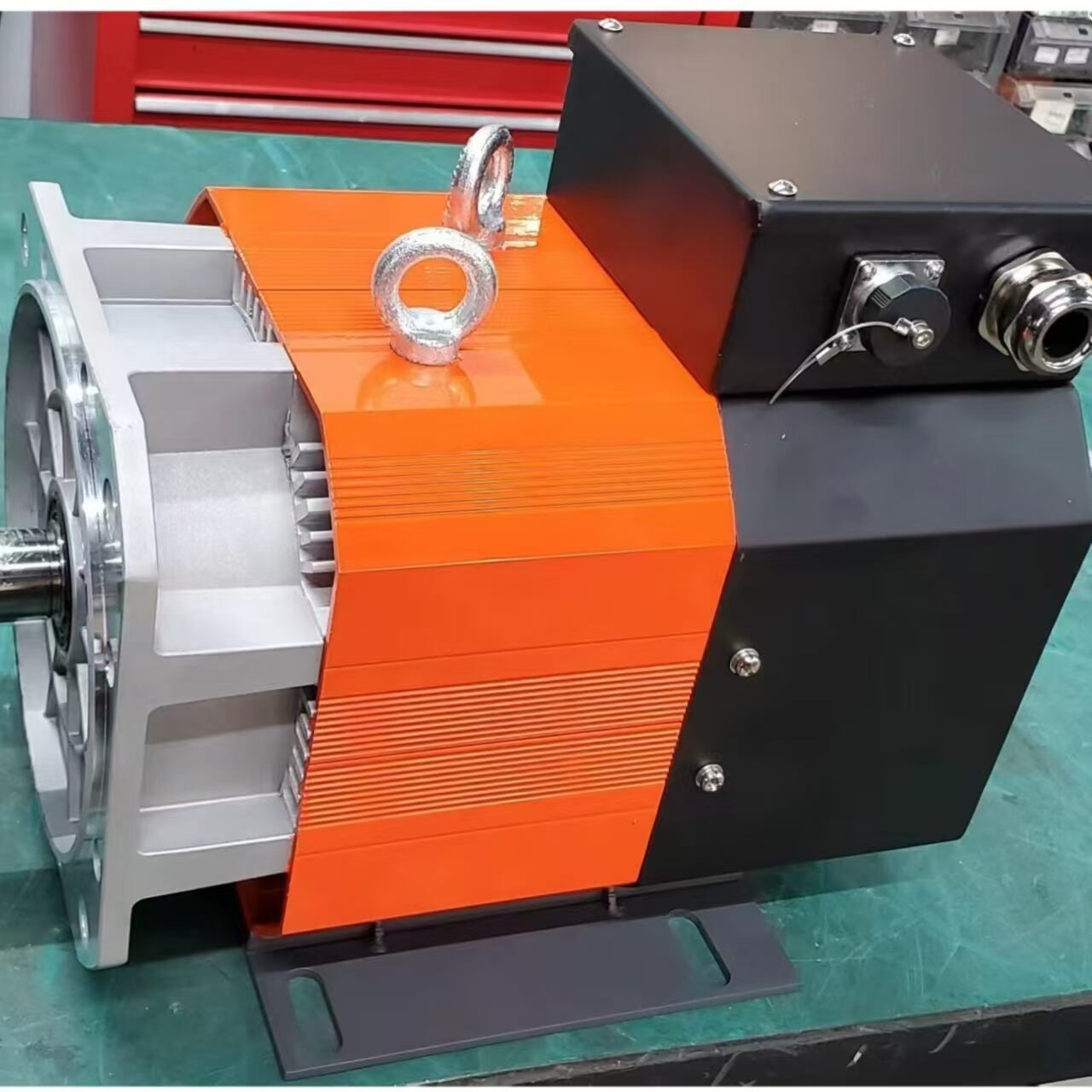

servo motori

Servo motori represent advanced electromechanical devices that deliver precise control over position, velocity, and acceleration in automated systems. These sophisticated motors integrate feedback mechanisms that continuously monitor and adjust their performance, ensuring exceptional accuracy in motion control applications. Operating through a closed-loop system, servo motors utilize encoders or resolvers to provide real-time position feedback, allowing for instantaneous corrections and maintaining desired parameters with remarkable precision. The technology incorporates permanent magnets, electronic commutation, and sophisticated control algorithms to achieve superior torque-to-inertia ratios and dynamic response characteristics. Modern servo motors feature advanced digital controllers that can be programmed for specific applications, offering flexibility across various industrial and commercial uses. They excel in applications requiring precise positioning, constant speed under varying loads, and rapid acceleration or deceleration. These motors find extensive use in robotics, CNC machinery, automated manufacturing lines, packaging equipment, and precision instruments where accuracy and reliability are paramount.