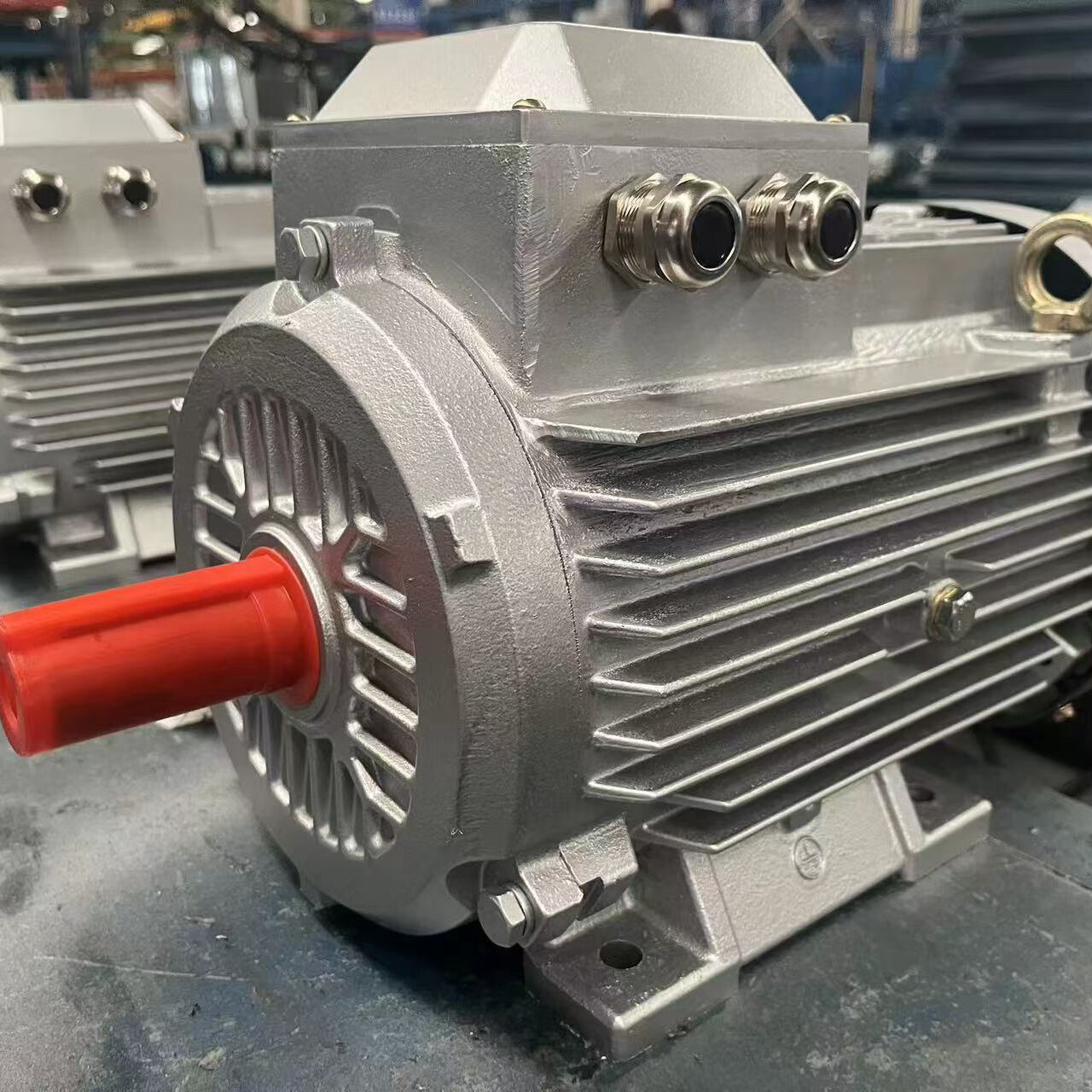

permanent magnet synchronous electric motor

The permanent magnet synchronous electric motor (PMSM) represents a cutting-edge advancement in electric motor technology, combining high efficiency with precise control capabilities. This sophisticated motor design incorporates permanent magnets in the rotor, which create a constant magnetic field that interacts with the rotating magnetic field generated by the stator windings. The synchronous operation means the rotor rotates at the same frequency as the rotating magnetic field, ensuring precise speed control and position accuracy. PMSMs excel in various applications due to their compact size, high power density, and superior performance characteristics. The motor's design enables exceptional torque production at low speeds while maintaining high efficiency across a broad operating range. These motors typically achieve efficiency ratings above 90%, making them ideal for energy-sensitive applications. In industrial settings, PMSMs drive precision machinery, robotics, and automated manufacturing systems. They're equally valuable in electric vehicles, where their high power-to-weight ratio and excellent control characteristics provide superior driving performance. The technology also finds extensive use in renewable energy systems, particularly in wind turbines, where reliability and efficiency are paramount. Modern PMSMs incorporate advanced features like integrated cooling systems, sophisticated control electronics, and robust construction methods that ensure long-term reliability and minimal maintenance requirements.