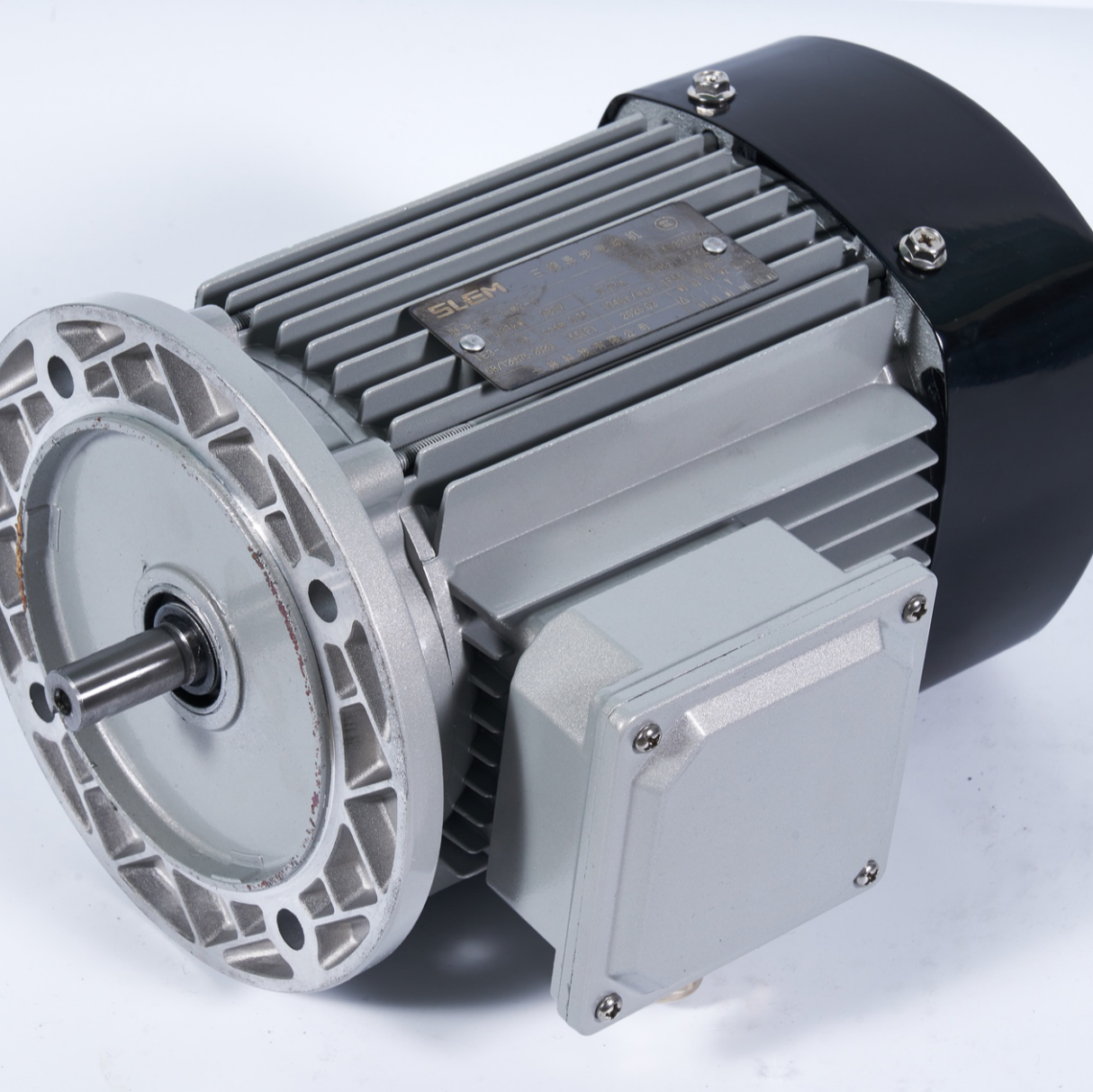

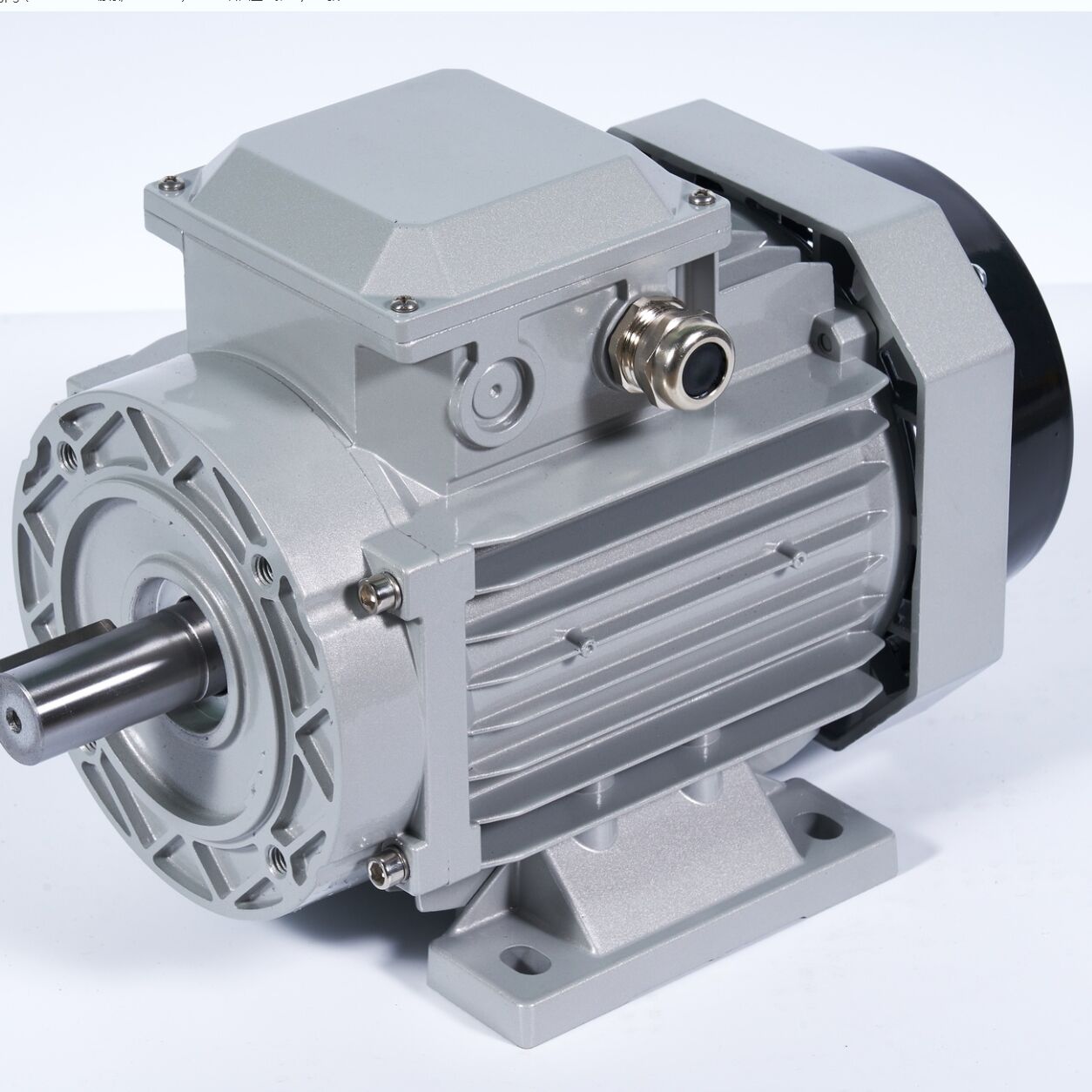

permanent magnet synchronous motor

The permanent magnet synchronous motor (PMSM) represents a cutting-edge innovation in electric motor technology, combining efficiency with reliable performance. This sophisticated motor design incorporates permanent magnets in the rotor structure, creating a consistent magnetic field that synchronizes perfectly with the rotating stator field. The PMSM operates by utilizing the interaction between the permanent magnets and the electromagnets in the stator, resulting in smooth, precise rotation at the exact frequency of the electrical supply. What sets the PMSM apart is its ability to maintain constant speed regardless of load variations, making it ideal for applications requiring precise speed control. The motor's design eliminates the need for separate excitation, reducing complexity and maintenance requirements. In industrial applications, PMSMs excel in driving machine tools, conveyor systems, and precision manufacturing equipment. Their compact size and high power density make them particularly valuable in space-constrained installations. The technology has also found widespread use in electric vehicles, renewable energy systems, and advanced robotics, where their superior efficiency and control characteristics provide significant advantages over conventional motors. With their ability to deliver high torque at low speeds and maintain excellent efficiency across their operating range, PMSMs have become increasingly important in modern industrial and commercial applications.