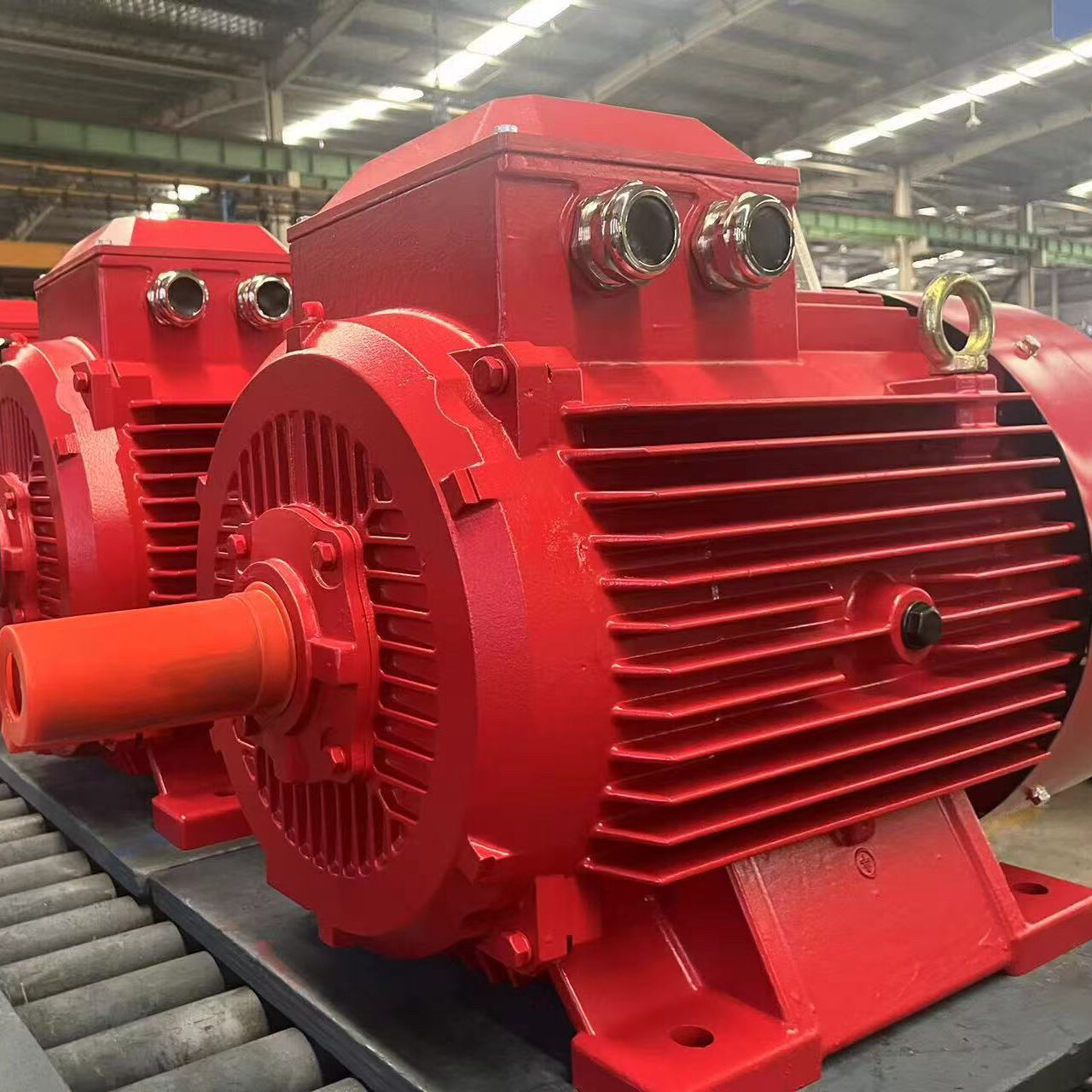

permanent synchronous motor

A permanent synchronous motor represents a sophisticated advancement in electric motor technology, combining the reliability of permanent magnets with synchronous operation principles. This motor type operates by utilizing permanent magnets embedded in the rotor, which interact with the rotating magnetic field produced by the stator windings. The motor maintains precise synchronization between the rotor speed and the frequency of the input power supply, ensuring consistent performance across various operating conditions. The design incorporates high-energy permanent magnets, typically made from rare earth materials such as neodymium-iron-boron, which provide exceptional magnetic field strength and stability. These motors excel in applications requiring precise speed control, high efficiency, and reliable operation. They are particularly valuable in industrial automation, HVAC systems, electric vehicles, and precision manufacturing equipment. The motor's construction allows for compact sizing while delivering superior torque density compared to conventional motor designs. Modern permanent synchronous motors often integrate advanced control systems and sensors to optimize performance and enable precise position control. This technology has become increasingly important in energy-efficient applications, where consistent speed control and reduced energy consumption are critical requirements.