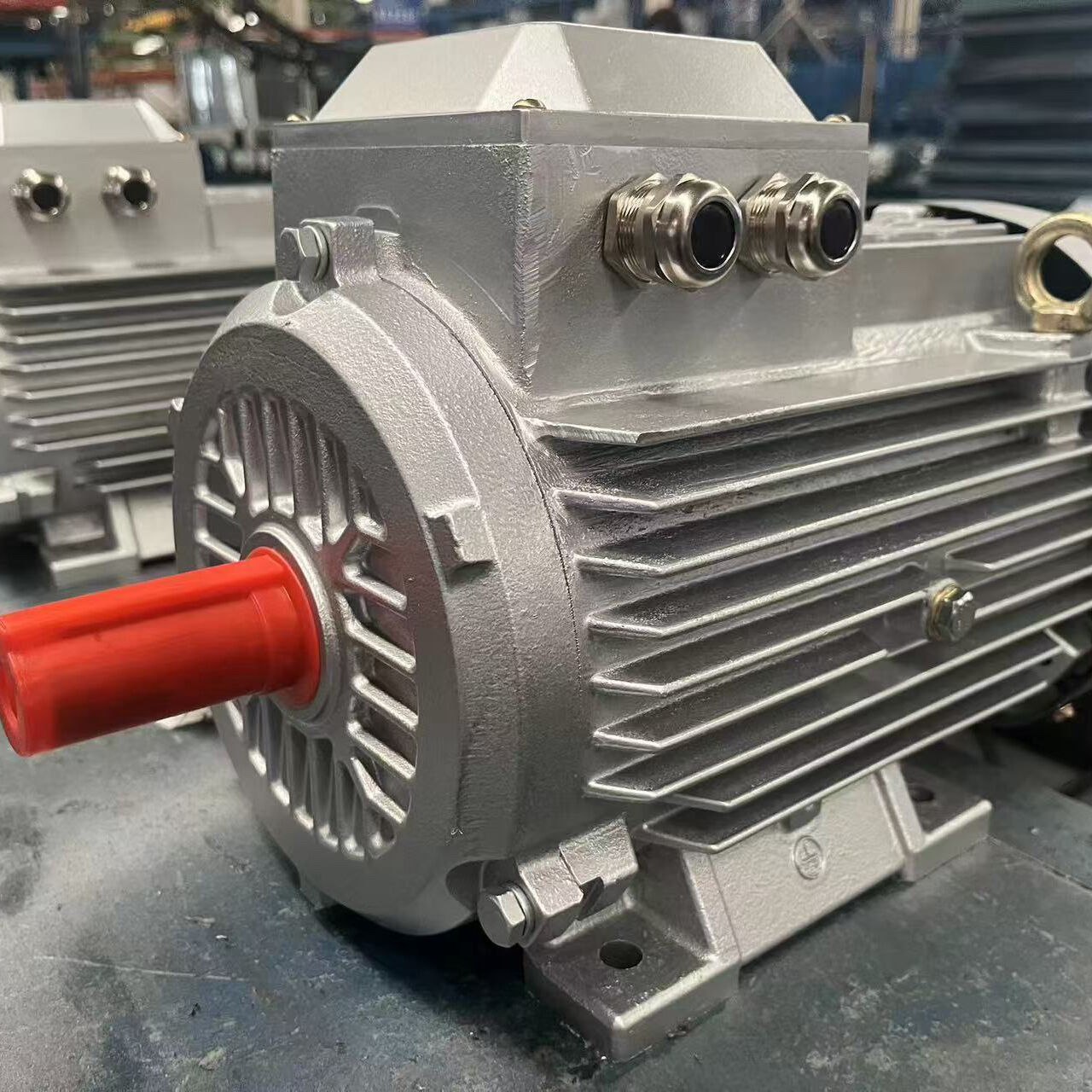

variable frequency motor

A variable frequency motor is a sophisticated piece of electrical equipment that combines an electric motor with a variable frequency drive (VFD) to provide precise speed and torque control. This innovative system operates by converting fixed frequency and voltage input power to variable frequency and voltage output, allowing for seamless speed adjustment and enhanced operational efficiency. The motor utilizes advanced electronic controls to modify the frequency of input power, thereby changing the motor's rotational speed and torque output. This technology enables users to fine-tune motor performance according to specific application requirements, from slow-speed precision tasks to high-speed operations. The system's ability to adjust motor speed eliminates the need for mechanical speed control devices, resulting in reduced maintenance requirements and improved system reliability. Variable frequency motors find extensive applications across various industries, including manufacturing, HVAC systems, conveyor systems, and process control equipment. They excel in applications requiring precise speed control, energy efficiency, and operational flexibility. The technology's sophisticated control algorithms ensure smooth acceleration and deceleration, protecting both the motor and connected equipment from mechanical stress.