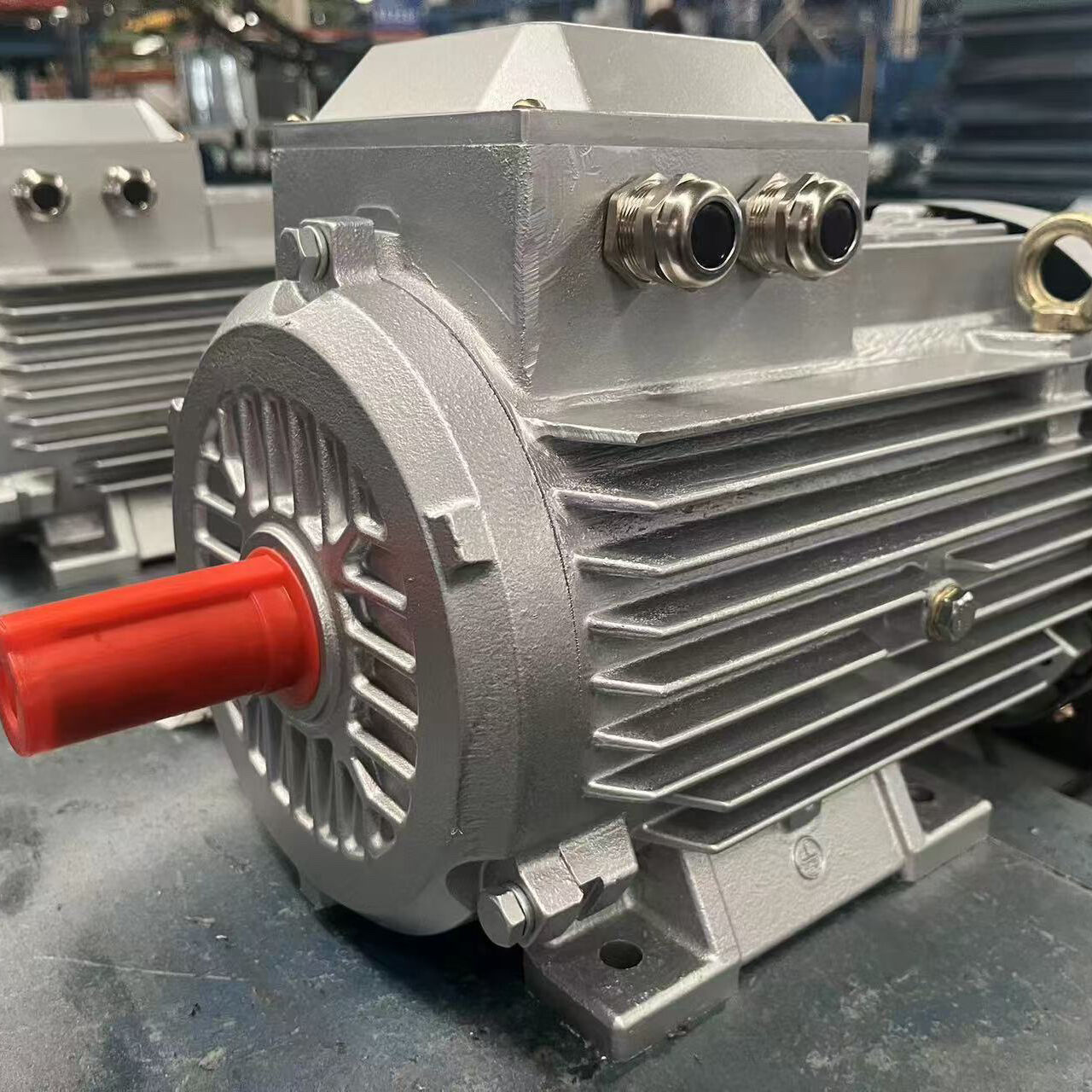

variable speed ac motor

A variable speed AC motor represents a sophisticated advancement in electric motor technology, offering precise control over operational speeds through the manipulation of frequency and voltage. This innovative motor system combines the reliability of AC power with the flexibility of adjustable speed control, making it an essential component in modern industrial applications. The motor operates by converting electrical energy into mechanical energy, with the unique ability to maintain optimal torque levels across various speed ranges. Its core functionality relies on a variable frequency drive (VFD) that modifies the input power frequency, enabling smooth speed adjustments without compromising performance. The technology incorporates advanced electronic controls that monitor and adjust motor parameters in real-time, ensuring efficient operation under varying load conditions. These motors are engineered with robust construction featuring high-grade electrical steel laminations, premium copper windings, and thermal protection systems. They excel in applications requiring precise speed control, such as conveyor systems, pumps, fans, and manufacturing equipment. The motor's design allows for soft starts and stops, reducing mechanical stress and extending equipment life while providing energy savings through optimized speed control.