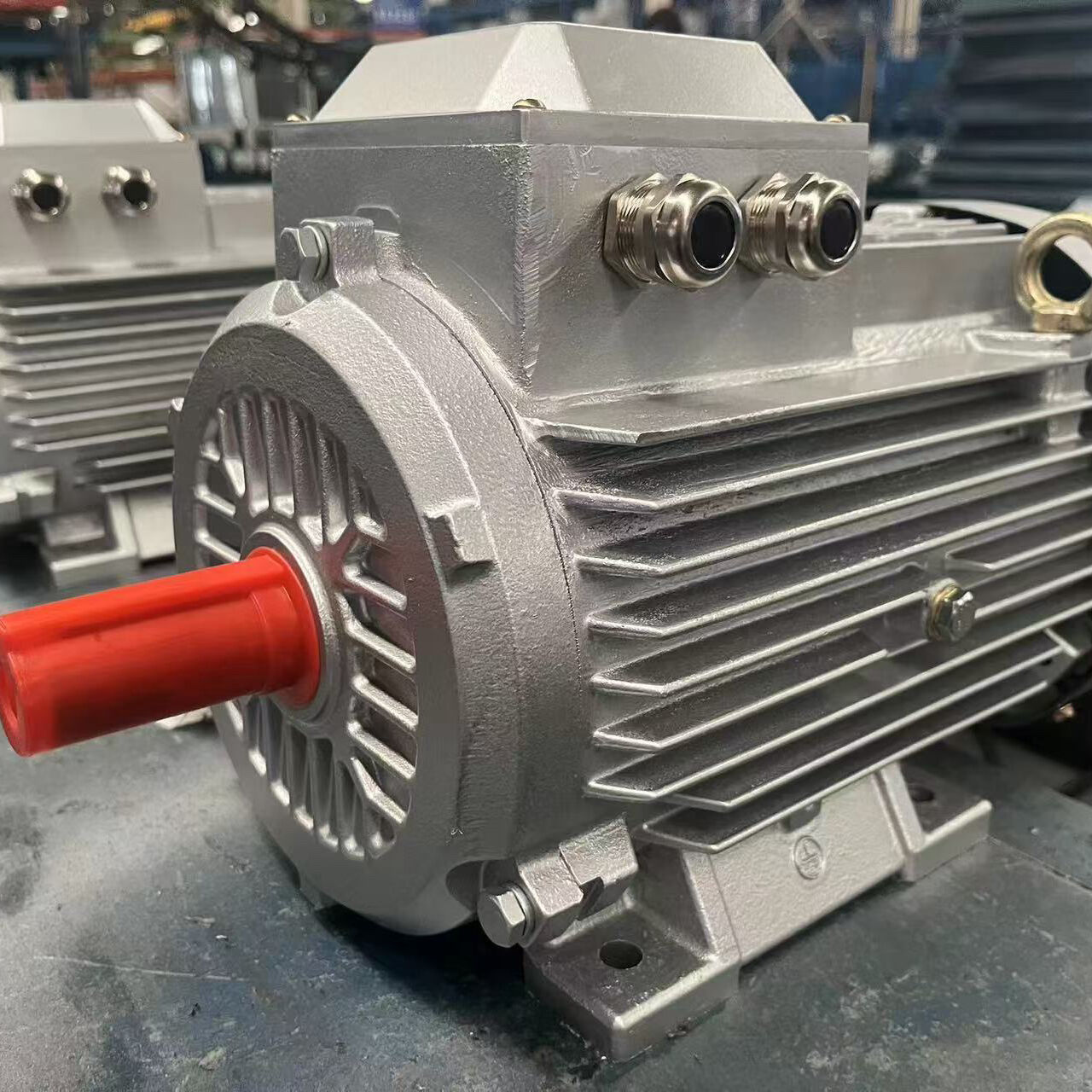

worm gearbox reducer

A worm gearbox reducer is a sophisticated power transmission device that combines worm gear technology with precision engineering to deliver efficient speed reduction and torque multiplication. This mechanical system consists of a worm screw and a matching worm wheel, working together to create a compact yet powerful reduction mechanism. The design allows for perpendicular shaft arrangement, making it ideal for applications where space optimization is crucial. The worm gear mechanism operates by having the worm screw's helical thread mesh with the teeth of the worm wheel, creating a smooth and continuous power transfer while significantly reducing output speed and increasing torque. These reducers are engineered with precision-machined components, often featuring high-grade materials such as hardened steel for the worm and phosphor bronze for the wheel, ensuring durability and reliability. Advanced lubrication systems and sealed housing designs protect the internal components from contamination while maintaining optimal operating conditions. The versatility of worm gearbox reducers makes them essential in various industrial applications, from conveyor systems and packaging machinery to elevators and material handling equipment. Their ability to handle high reduction ratios in a single stage, coupled with their self-locking capabilities, provides both operational efficiency and safety benefits.