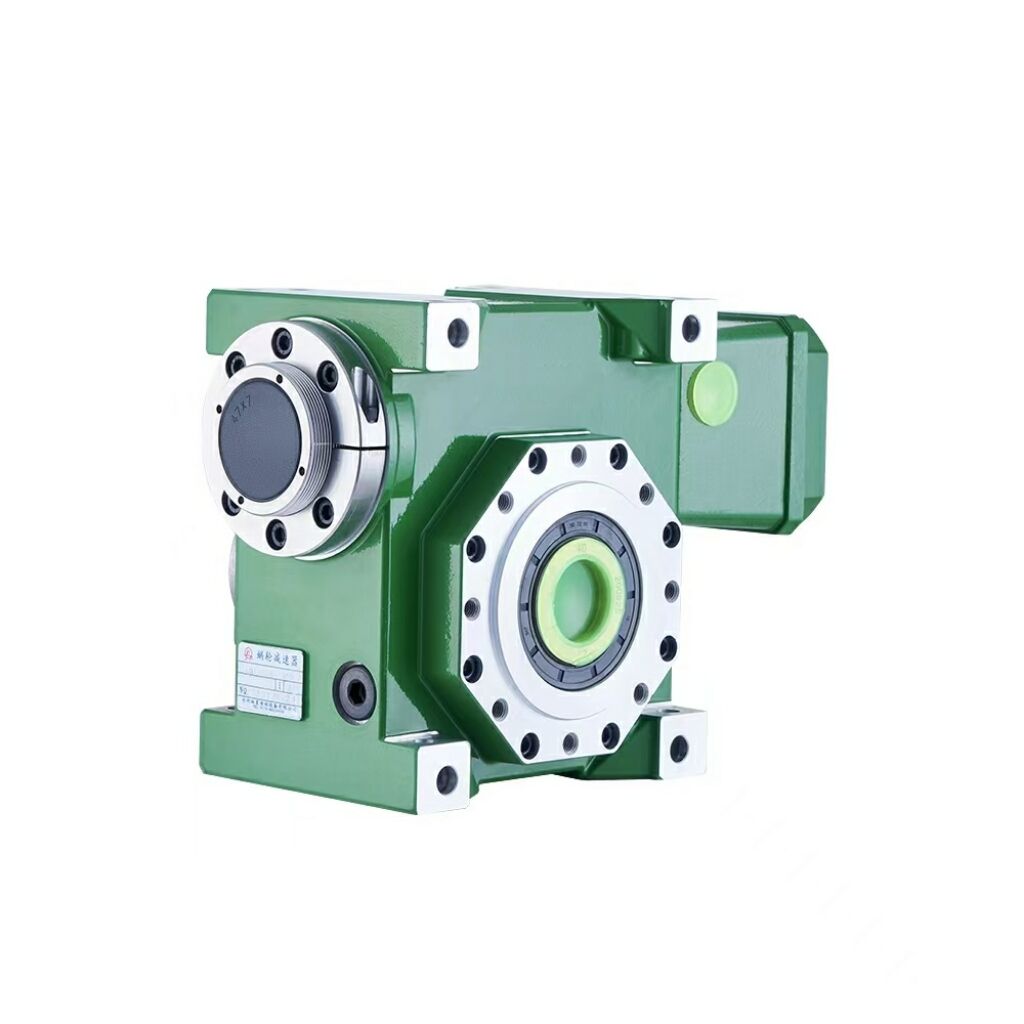

double reduction worm gearbox

A double reduction worm gearbox is an advanced power transmission system that combines two stages of reduction through worm gear mechanisms. This sophisticated design enables the conversion of high-speed, low-torque input into low-speed, high-torque output, making it essential for various industrial applications. The system consists of two sets of worm gears arranged in series, where the first stage reduces the input speed initially, and the second stage further reduces it to achieve the desired output specifications. The primary worm gear transfers motion to an intermediate shaft, which then connects to a secondary worm gear assembly for additional reduction. This dual-stage configuration allows for higher reduction ratios compared to single-stage worm gearboxes, typically achieving ratios from 200:1 to 10000:1. The design incorporates precision-engineered worm shafts, worm wheels, and bearings, all housed within a robust casing that ensures proper lubrication and heat dissipation. The gearbox's construction typically features high-grade materials such as hardened steel for the worms and phosphor bronze for the worm wheels, ensuring durability and reliable performance under heavy loads.