Critical Considerations for Optimal Gear Reducer Selection

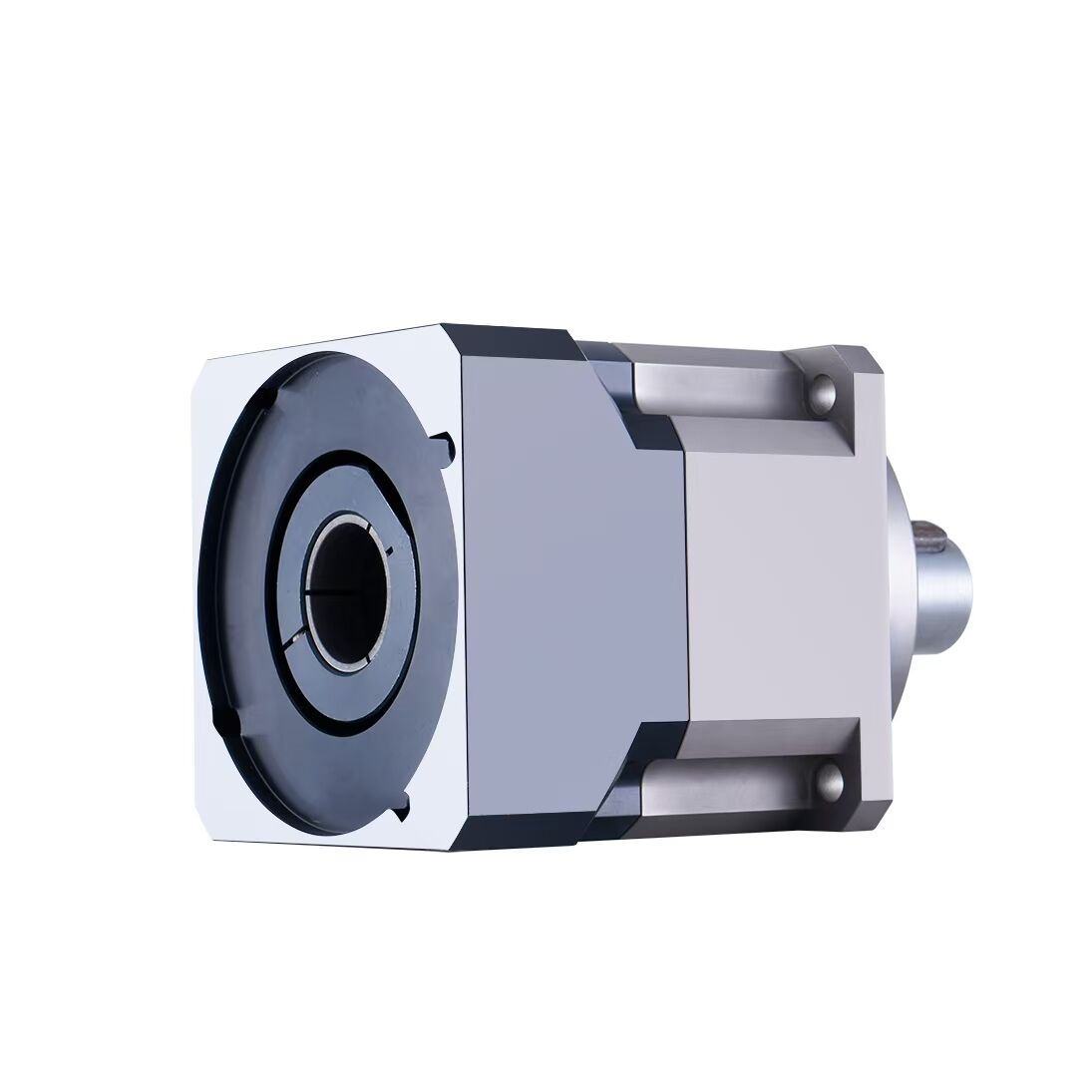

Planetary gear reducers represent precision power transmission components that require careful evaluation to ensure proper system integration and performance. These compact, high-torque devices serve as the backbone of countless motion control systems across industrial automation, robotics, and heavy machinery applications. Selecting the right planetary gear reducer involves balancing multiple technical parameters with operational requirements and environmental factors. The ideal planetary gear reducer must not only meet immediate torque and speed requirements but also provide long-term reliability under anticipated operating conditions. Understanding the key selection criteria helps engineers specify planetary gear reducers that maximize system performance while minimizing lifetime costs.

Torque and Power Requirements

Determining Operational Torque Needs

Accurate torque calculation forms the foundation of planetary gear reducer selection. Engineers must consider both continuous and peak torque requirements when specifying a planetary gear reducer for any application. The rated torque of a planetary gear reducer should exceed the application's maximum operational torque with an appropriate safety factor. Dynamic torque loads caused by acceleration, deceleration, or shock conditions require special consideration as they may exceed static calculations. Planetary gear reducers with higher torque capacity often incorporate hardened gear teeth and precision bearings to handle demanding load cycles. Understanding torque curves across the entire speed range ensures the selected planetary gear reducer performs optimally under all operating conditions.

Power Transmission Efficiency Factors

The mechanical efficiency of a planetary gear reducer directly impacts overall system performance and energy consumption. High-quality planetary gear reducers typically achieve 90-97% efficiency per reduction stage through precision gear manufacturing and optimized bearing arrangements. Efficiency losses in planetary gear reducers primarily result from gear mesh friction, bearing friction, and lubricant churning. Applications requiring continuous operation or energy-sensitive designs should prioritize planetary gear reducers with verified efficiency ratings. Some advanced planetary gear reducer models incorporate low-friction coatings or specialized lubricants to maximize power transmission efficiency. The cumulative effect of small efficiency improvements becomes significant in systems operating thousands of hours annually.

Speed and Reduction Ratio Specifications

Input Speed Capabilities

Planetary gear reducers must withstand the input speeds generated by prime movers, whether electric motors, hydraulic systems, or internal combustion engines. Excessive input speeds can cause lubricant breakdown, gear tooth pitting, or bearing failure in planetary gear reducers. Manufacturers specify maximum input speed ratings based on gear tooth geometry, bearing types, and lubrication methods. High-speed applications may require planetary gear reducers with specialized oil lubrication systems rather than standard grease lubrication. Some planetary gear reducer designs incorporate balancing features to minimize vibration at elevated rotational speeds. Matching the reducer's speed capability to the application prevents premature wear and ensures reliable operation.

Optimal Reduction Ratio Selection

The reduction ratio of a planetary gear reducer determines the relationship between input and output speeds while multiplying available torque. Common planetary gear reducer ratios range from 3:1 to 100:1 in single-stage designs, with multi-stage units achieving higher reductions. Selecting the appropriate reduction ratio involves analyzing speed requirements, torque multiplication needs, and motor characteristics. Planetary gear reducers with ratio options that place the prime mover in its optimal efficiency range often yield the best system performance. Some applications benefit from planetary gear reducers with customizable ratio options that fine-tune machine operation. Over-sizing the reduction ratio can lead to unnecessary cost while under-sizing may compromise performance.

Physical Dimensions and Mounting Considerations

Space Constraints and Envelope Requirements

The compact nature of planetary gear reducers makes them ideal for space-limited applications, but proper dimensional evaluation remains crucial. Engineers must verify that the selected planetary gear reducer fits within available machine space while allowing adequate clearance for maintenance. Hollow shaft planetary gear reducer designs often simplify integration by enabling through-shaft mounting or internal cable routing. Flange-mounted planetary gear reducers require consideration of bolt circle dimensions and interface tolerances. Some applications benefit from planetary gear reducers with modular designs that allow flexible orientation changes during installation. Careful measurement of all spatial constraints prevents costly redesigns during machine assembly.

Mounting Configuration Options

Planetary gear reducers are available in various mounting configurations to suit different mechanical designs. Common options include flange-mounted, foot-mounted, and shaft-mounted planetary gear reducers, each with distinct advantages. The mounting style affects load distribution, accessibility, and overall system stiffness. Torque-arm mounted planetary gear reducers help counteract reaction forces in certain applications. Many modern planetary gear reducers feature standardized mounting interfaces that simplify integration with common motor types. Selecting the appropriate mounting configuration ensures optimal load paths and minimizes stress concentrations that could affect reducer or machine frame longevity.

Precision and Backlash Requirements

Backlash Specifications for Positioning Accuracy

The backlash rating of a planetary gear reducer significantly impacts system positioning accuracy in motion control applications. Precision planetary gear reducers achieve low backlash through gear tooth profile optimization, preloaded bearings, and meticulous assembly processes. Applications like robotics or CNC machinery often require planetary gear reducers with backlash ratings below 5 arc-minutes. Standard industrial applications may tolerate planetary gear reducers with higher backlash levels up to 15 arc-minutes. Some planetary gear reducer manufacturers offer adjustable backlash versions that maintain precision throughout the service life. Understanding the application's positional tolerance requirements guides appropriate backlash specification.

Torsional Stiffness Considerations

The torsional stiffness of a planetary gear reducer affects system responsiveness and vibration characteristics. High-stiffness planetary gear reducers minimize angular deflection under load, maintaining precise motion control. Stiffness ratings depend on gear material selection, bearing types, and overall reducer construction. Applications involving rapid acceleration or precise contouring benefit from planetary gear reducers with optimized stiffness characteristics. Some manufacturers provide torsional stiffness curves that help predict performance under varying load conditions. Planetary gear reducers with high stiffness-to-weight ratios are particularly valuable in dynamic applications where inertia affects system response.

Environmental and Operational Conditions

Temperature Range and Lubrication Requirements

Planetary gear reducers must perform reliably across the application's expected temperature extremes. Standard planetary gear reducers typically operate between -20°C and 90°C, with special versions available for wider ranges. Lubrication selection plays a critical role in temperature performance, with synthetic oils extending the operating range of planetary gear reducers in extreme conditions. High-temperature applications may require planetary gear reducers with special seals and heat-resistant materials. Conversely, cold environments demand planetary gear reducers with low-temperature lubricants that maintain proper viscosity. Verifying temperature specifications prevents lubricant failure or material degradation in challenging environments.

Contamination and Ingress Protection

The IP rating of a planetary gear reducer indicates its protection against dust and moisture ingress. Industrial environments often require planetary gear reducers with IP65 or higher ratings to withstand washdown conditions or airborne contaminants. Sealed planetary gear reducers prevent lubricant leakage while excluding external contaminants that could accelerate wear. Food processing or pharmaceutical applications may need planetary gear reducers with special coatings or stainless steel construction for cleanability. Some heavy-duty planetary gear reducers incorporate additional sealing for protection against abrasive particles in mining or construction applications. Matching the protection level to the operating environment extends service life and reduces maintenance frequency.

Reliability and Maintenance Factors

Expected Service Life Calculations

The design life of a planetary gear reducer depends on load conditions, operating hours, and maintenance practices. Manufacturers typically provide L10 life ratings based on bearing fatigue calculations under specified loads. High-cycle applications should select planetary gear reducers with demonstrated longevity under similar duty cycles. Factors like shock loads, vibration, and misalignment can significantly reduce the actual service life of planetary gear reducers. Some premium planetary gear reducers incorporate wear-resistant materials and optimized tooth profiles that extend operational life. Understanding application duty cycles helps specify planetary gear reducers that meet reliability expectations without unnecessary overdesign.

Maintenance Requirements and Accessibility

Planetary gear reducers vary in their maintenance needs from sealed-for-life designs to units requiring regular lubrication. The maintenance schedule should align with the application's operational requirements and accessibility constraints. Some planetary gear reducers feature easy-access lubrication points that minimize downtime during service. Remotely mounted planetary gear reducers in difficult-to-access locations may benefit from extended lubrication intervals or automatic lubrication systems. Maintenance-friendly planetary gear reducers with tool-less inspection covers simplify routine checks and reduce service time. Considering long-term maintenance needs during selection prevents operational disruptions and reduces total cost of ownership.

Cost and Value Considerations

Initial Cost vs. Lifetime Value Analysis

While price remains a consideration, the total value proposition of a planetary gear reducer encompasses multiple factors beyond initial purchase cost. High-quality planetary gear reducers often demonstrate lower lifetime costs through extended service life, reduced downtime, and lower maintenance requirements. Energy-efficient planetary gear reducers may justify higher initial costs through power savings in continuous operation applications. Some planetary gear reducer designs reduce associated costs by simplifying installation or eliminating ancillary components. Evaluating total cost of ownership rather than just purchase price leads to more informed selection decisions.

Availability and Supply Chain Factors

The lead time and availability of planetary gear reducers can significantly impact project schedules and machine uptime. Standardized planetary gear reducers with broad industry acceptance typically offer better availability than specialized custom units. Some manufacturers provide modular planetary gear reducer systems that allow quick configuration of common specifications. Global supply chain considerations may favor planetary gear reducers with multiple manufacturing sources or local stock availability. Applications requiring quick replacement or potential future expansion benefit from selecting planetary gear reducers with reliable supply channels.

FAQ

How do I determine the proper service factor for a planetary gear reducer?

Service factors typically range from 1.0 to 2.0 based on application severity, with higher factors for shock loads or unpredictable conditions - consult manufacturer guidelines for specific recommendations.

Can planetary gear reducers handle axial and radial loads simultaneously?

Quality planetary gear reducers are designed for combined loading, but actual capacity depends on bearing arrangements - always verify load ratings with the manufacturer.

What's the difference between single-stage and multi-stage planetary gear reducers?

Single-stage units provide ratios up to ~10:1 with higher efficiency, while multi-stage planetary gear reducers achieve greater reductions (up to 100:1+) in a compact package with slightly lower efficiency.

Table of Contents

- Critical Considerations for Optimal Gear Reducer Selection

- Torque and Power Requirements

- Speed and Reduction Ratio Specifications

- Physical Dimensions and Mounting Considerations

- Precision and Backlash Requirements

- Environmental and Operational Conditions

- Reliability and Maintenance Factors

- Cost and Value Considerations

- FAQ