Optimizing Performance and Longevity for High Voltage Electrical Systems

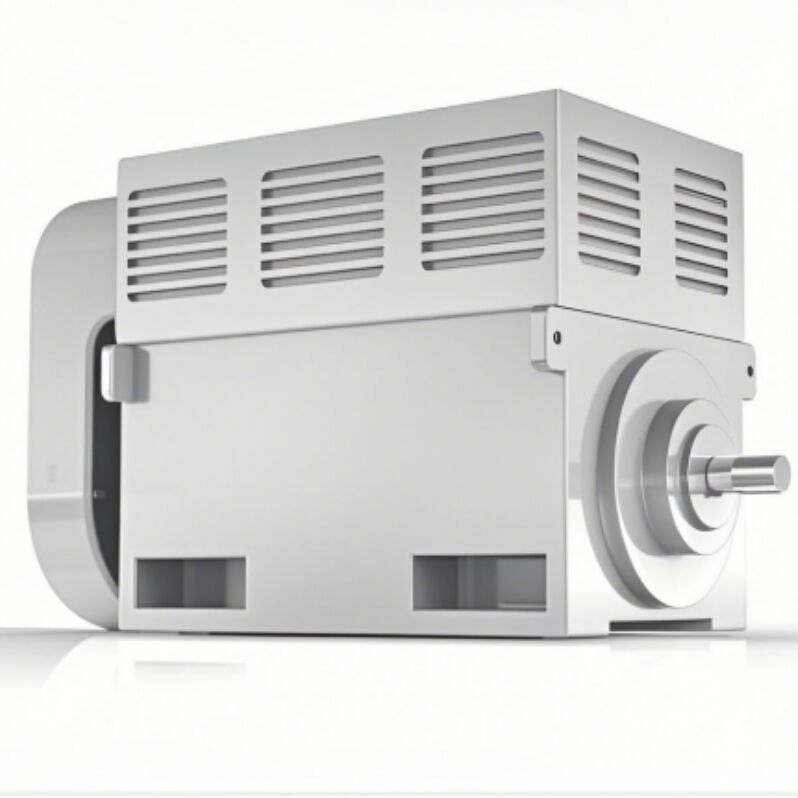

High voltage motors represent significant capital investments in industrial operations, making their proper maintenance essential for maximizing service life and operational efficiency. These powerful workhorses drive critical processes across industries from manufacturing to energy production, where unexpected downtime can have substantial financial consequences. Implementing comprehensive maintenance practices for high voltage motors not only extends equipment lifespan but also improves energy efficiency and reduces the likelihood of catastrophic failures. The unique characteristics of high voltage motors - including their insulation systems, cooling requirements, and electrical components - demand specialized maintenance approaches that differ from standard motor care protocols. By understanding and addressing the specific needs of high voltage motors, maintenance teams can significantly enhance reliability while controlling long-term operational costs.

Routine Inspection and Monitoring Protocols

Visual and Mechanical Condition Assessments

Regular visual inspections form the foundation of effective high voltage motor maintenance programs. Technicians should examine high voltage motors for signs of contamination, moisture ingress, or physical damage to casings and cooling systems. Bearing housings on high voltage motors require particular attention, checking for lubricant leaks or unusual wear patterns that could indicate alignment issues. Vibration analysis during operation helps identify developing mechanical problems in high voltage motors before they cause serious damage. Infrared thermography scans of high voltage motors can reveal hot spots in windings or connections that may signal impending failures. These non-invasive inspection techniques allow for early intervention while high voltage motors remain in service.

Electrical System Evaluations

Comprehensive electrical testing provides crucial insights into the health of high voltage motors. Insulation resistance testing (megger testing) on high voltage motors should be performed regularly to assess winding insulation integrity. Polarization index tests offer more detailed information about insulation quality in high voltage motors by measuring resistance values over extended periods. Surge comparison testing helps detect turn-to-turn insulation weaknesses in high voltage motor windings that standard tests might miss. Partial discharge monitoring systems can be installed on critical high voltage motors to continuously assess insulation condition during operation. These electrical evaluations help predict when high voltage motors may require rewinding or other major maintenance.

Lubrication Management Strategies

Bearing Lubrication Best Practices

Proper lubrication significantly impacts the lifespan of high voltage motors, particularly in their bearing systems. High voltage motors often require premium-grade greases specifically formulated for their operating temperatures and speeds. Lubrication intervals for high voltage motors should be based on actual operating hours rather than calendar time, accounting for varying duty cycles. Over-lubrication can be as harmful as under-lubrication in high voltage motors, causing grease breakdown and increased operating temperatures. Automated lubrication systems provide precise grease quantities at programmed intervals for large high voltage motors in difficult-to-access locations. Proper lubrication procedures help prevent bearing failures that account for a significant percentage of high voltage motor breakdowns.

Oil Analysis and Contamination Control

For high voltage motors with oil-lubricated bearings, regular oil analysis provides valuable condition monitoring data. Particle counting tests on lubricant samples from high voltage motors can detect abnormal wear patterns before they cause damage. Spectrochemical analysis identifies the presence of wear metals or contaminants in high voltage motor lubrication systems. Water content testing is particularly important for high voltage motors operating in humid environments where moisture ingress can degrade lubricant performance. Maintaining proper oil levels and implementing effective filtration systems helps preserve high voltage motor components. These oil analysis practices enable predictive maintenance rather than reactive repairs on critical high voltage motors.

Thermal Management and Cooling System Maintenance

Air Cooling System Maintenance

Effective cooling is essential for maintaining optimal operating temperatures in high voltage motors. Air-cooled high voltage motors require regular cleaning of ventilation ducts and heat exchange surfaces to prevent overheating. Filters on forced-air cooling systems for high voltage motors should be inspected and replaced according to manufacturer recommendations. Air gap measurements between rotor and stator help ensure proper cooling airflow in large high voltage motors. Thermographic surveys can identify blocked cooling passages or uneven temperature distribution in high voltage motors. Maintaining clean, unobstructed cooling systems prevents thermal stress that degrades high voltage motor insulation and bearings.

Liquid Cooling System Care

High voltage motors with water or oil cooling systems demand specialized maintenance attention. Cooling fluid chemistry should be regularly tested and treated to prevent corrosion or scaling in high voltage motor cooling jackets. Flow rate monitoring ensures adequate heat removal from liquid-cooled high voltage motors during operation. Strainers and filters in cooling loops protecting high voltage motors require periodic cleaning to maintain proper flow. Pressure testing of cooling system components helps detect leaks before they cause high voltage motor damage. Winterization procedures prevent freezing damage to cooling systems in high voltage motors located in cold environments. Proper cooling system maintenance directly impacts the efficiency and longevity of high voltage motors.

Electrical Connection and Winding Maintenance

Terminal and Connection Inspections

Electrical connections represent potential failure points in high voltage motors that require regular attention. Torque checks on power cable connections prevent loosening that could cause overheating in high voltage motors. Infrared inspections identify hot spots at termination points that may indicate deteriorating connections. Corona inspections using ultraviolet cameras detect electrical discharge activity around high voltage motor terminals. Connection surfaces should be cleaned and treated with appropriate compounds to minimize oxidation. Proper bushing maintenance prevents moisture ingress that could compromise high voltage motor insulation systems. These connection maintenance practices reduce electrical resistance and prevent catastrophic failures.

Winding Maintenance and Repair

The winding systems in high voltage motors require specialized care to maintain insulation integrity. Regular megger testing tracks insulation resistance trends in high voltage motor windings over time. Winding temperature monitoring systems provide real-time data about thermal conditions within operating high voltage motors. Partial discharge testing helps assess insulation condition in high voltage motor windings without requiring disassembly. When rewinding becomes necessary for high voltage motors, using Class F or H insulation materials extends future service life. Proper winding tension and impregnation during repairs maintains mechanical stability in high voltage motor windings. These practices preserve the electrical integrity of high voltage motors through multiple maintenance cycles.

Alignment and Vibration Control

Precision Alignment Procedures

Proper alignment between high voltage motors and driven equipment significantly impacts mechanical lifespan. Laser alignment tools provide the accuracy needed for large high voltage motor installations. Thermal growth considerations must be factored into alignment of high voltage motors that experience significant temperature variations. Soft foot conditions should be corrected during high voltage motor alignment to prevent frame distortion. Coupling maintenance is equally important, with regular inspections of flexible elements in high voltage motor drive trains. Proper alignment reduces vibration and bearing loads that could otherwise shorten high voltage motor service life.

Vibration Monitoring and Analysis

Continuous vibration monitoring provides early warning of developing problems in high voltage motors. Online vibration monitoring systems can detect imbalances, misalignment, or bearing wear in operating high voltage motors. Baseline vibration signatures should be established for high voltage motors during initial commissioning for comparison with future readings. Spectral analysis of vibration data helps diagnose specific mechanical issues in high voltage motors. Temporary vibration monitoring may be warranted following repairs or when high voltage motors exhibit unusual behavior. Effective vibration management prevents minor issues from escalating into major failures in high voltage motors.

Environmental Protection and Hazard Mitigation

Contamination and Moisture Control

Protecting high voltage motors from environmental hazards significantly extends their operational life. Enclosure integrity checks prevent dust and moisture ingress that could damage high voltage motor internals. Desiccant breathers maintain proper humidity levels within high voltage motor enclosures. Regular cleaning prevents conductive dust accumulation on high voltage motor windings and connections. Corrosion protection measures are particularly important for high voltage motors in coastal or chemically aggressive environments. Space heaters in high voltage motor enclosures prevent condensation during idle periods. These protective measures preserve electrical and mechanical integrity in challenging operating conditions.

Hazardous Area Considerations

High voltage motors operating in explosive atmospheres require additional maintenance precautions. Regular inspections ensure explosion-proof enclosures on high voltage motors maintain their protective integrity. Special attention must be paid to flame path maintenance on explosion-proof high voltage motors. Certification labels and safety markings should remain legible on hazardous area high voltage motors. Intrinsically safe measurement techniques must be used when testing high voltage motors in classified locations. Maintenance personnel working on hazardous area high voltage motors require specialized training. These additional precautions ensure safe operation while preserving equipment lifespan.

Maintenance Documentation and Trend Analysis

Comprehensive Record Keeping

Detailed maintenance records provide invaluable data for optimizing high voltage motor care strategies. Service logs should document all inspections, tests, and repairs performed on high voltage motors. Trend analysis of vibration data, temperature readings, and electrical tests helps predict high voltage motor maintenance needs. Digital maintenance management systems can track the complete service history of high voltage motors throughout their lifecycle. Photographic documentation provides visual references for comparing high voltage motor condition over time. Accurate records support data-driven decisions about repair versus replacement of aging high voltage motors.

Performance Benchmarking

Establishing and tracking key performance indicators helps evaluate high voltage motor maintenance effectiveness. Energy consumption trends provide insight into the efficiency degradation of high voltage motors over time. Mean time between failures (MTBF) metrics help assess the reliability of different high voltage motor populations. Maintenance cost tracking identifies opportunities to improve high voltage motor lifecycle economics. Comparing performance data across similar high voltage motors highlights potential outliers requiring special attention. These analytical approaches transform maintenance from reactive to strategic for high voltage motor populations.

FAQ

How often should insulation resistance tests be performed on high voltage motors?

Most experts recommend quarterly megger testing for critical high voltage motors, with monthly tests for units in harsh environments or showing signs of insulation degradation.

What are the signs that a high voltage motor needs bearing replacement?

Common indicators include increased vibration, unusual noises, elevated bearing temperatures, and lubricant contamination with metal particles in high voltage motors.

Can high voltage motors be rewound indefinitely?

While technically possible, most industry standards recommend no more than 2-3 rewinds for high voltage motors to maintain reliability and efficiency, with careful evaluation after each repair.

Table of Contents

- Optimizing Performance and Longevity for High Voltage Electrical Systems

- Routine Inspection and Monitoring Protocols

- Lubrication Management Strategies

- Thermal Management and Cooling System Maintenance

- Electrical Connection and Winding Maintenance

- Alignment and Vibration Control

- Environmental Protection and Hazard Mitigation

- Maintenance Documentation and Trend Analysis

- FAQ