বিদ্যুৎ উৎপাদন এবং পরিচালনার ক্ষেত্রে ধ্রুবক দক্ষতা বজায় রাখতে উচ্চ-ভোল্টেজ মোটরের উপর বিদ্যুৎ কেন্দ্রগুলির অত্যধিক নির্ভরতা রয়েছে। টারবাইন জেনারেটর থেকে শুরু করে শীতলীকরণ পাম্প পর্যন্ত সবকিছু চালানোর ক্ষেত্রে আধুনিক শক্তি অবকাঠামোর মূল ভিত্তি গঠন করে এই গুরুত্বপূর্ণ উপাদানগুলি।

আরও দেখুন

শিল্প স্বয়ংক্রিয়করণ এবং রোবোটিক্সের দ্রুত বিকশিত ক্ষেত্রে, সর্বোত্তম কর্মক্ষমতা এবং নির্ভরযোগ্যতা অর্জনের জন্য সূক্ষ্ম গতি নিয়ন্ত্রণ একটি মৌলিক প্রয়োজনীয়তা হিসাবে দাঁড়িয়েছে। উপযুক্ত ট্রান্সমিশন সিস্টেমের নির্বাচন সরাসরি প্রভাব ফেলে...

আরও দেখুন

আধুনিক শিল্প স্বয়ংক্রিয়করণ এমন ড্রাইভ সিস্টেমের জন্য ক্রমাগত চাহিদা তৈরি করে যা অসাধারণ কর্মক্ষমতা প্রদান করে এবং সঙ্গে সঙ্গে কমপ্যাক্ট আকৃতি বজায় রাখে। উৎপাদন খাতের প্রকৌশলীরা ধ্রুবকভাবে এমন সমাধান খুঁজছেন যা কোনও আপস ছাড়াই দক্ষতা সর্বোচ্চ করে...

আরও দেখুন

সদ্য কয়েক দশকে শিল্প খাতে উল্লেখযোগ্য পরিবর্তন এসেছে, যেখানে শক্তির দক্ষতা বিশ্বব্যাপী উৎপাদনকারীদের জন্য সর্বোচ্চ গুরুত্বপূর্ণ বিষয় হয়ে উঠেছে। আজকের বিভিন্ন মোটর প্রযুক্তির মধ্যে, স্থায়ী চুম্বক সিঙ্ক্রোনাস...

আরও দেখুন

উৎপাদন, খনি, নির্মাণ এবং প্রক্রিয়াকরণ শিল্পের মতো শিল্প কার্যক্রমগুলি চাপা কাজের ভার সামলানোর জন্য দৃঢ় যান্ত্রিক ব্যবস্থার উপর অত্যন্ত নির্ভরশীল। এই ব্যবস্থাগুলির কেন্দ্রে রয়েছে গিয়ার রিডিউসার, জটিল যান্ত্রিক ডিভাইস যা...

আরও দেখুন

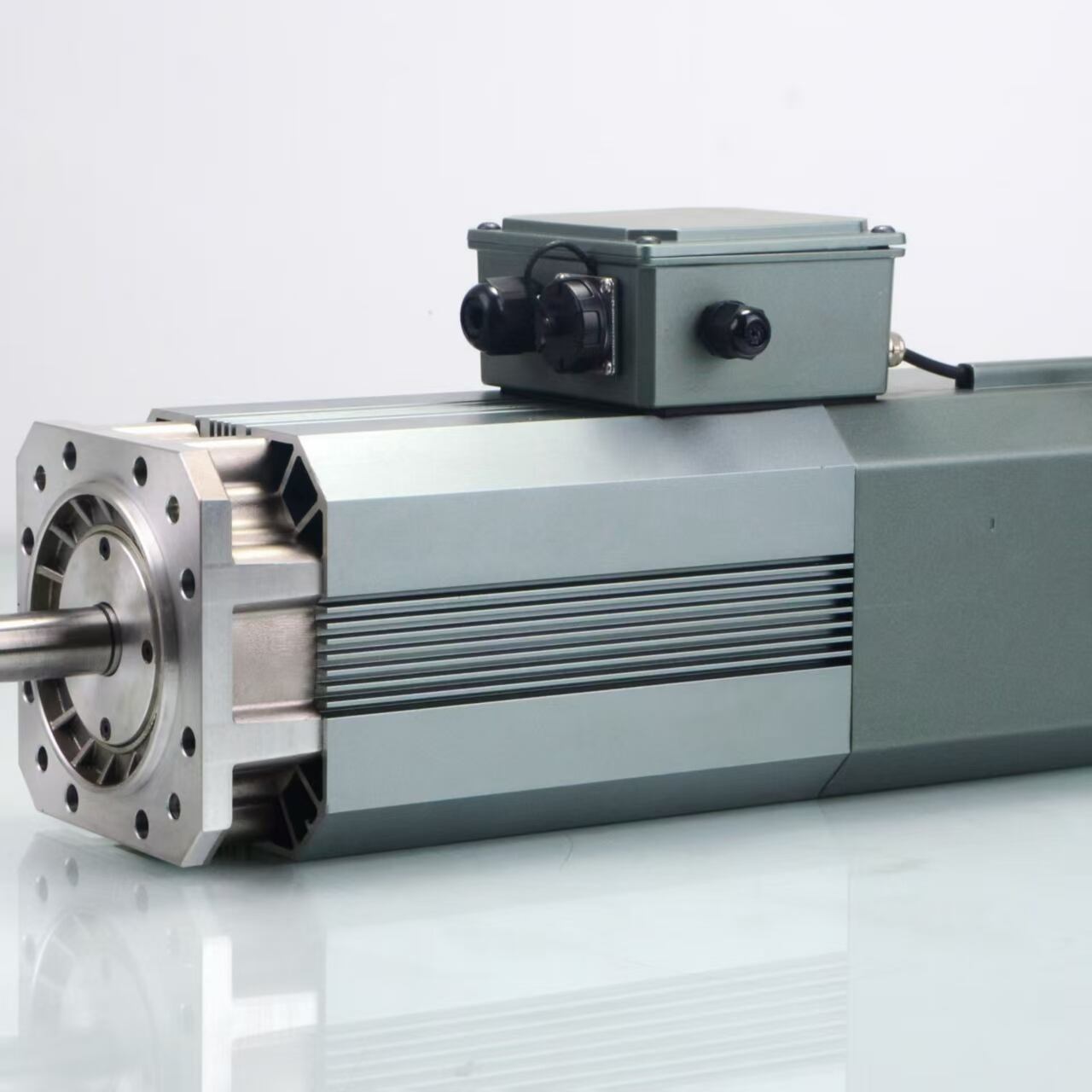

আজকের দ্রুত পরিবর্তনশীল শিল্প পরিবেশে, সঠিক মোটর প্রযুক্তি নির্বাচন করা কার্যকরী দক্ষতা এবং শক্তি খরচের উপর গুরুত্বপূর্ণ প্রভাব ফেলতে পারে। আধুনিক অটোমেশন সিস্টেমের একটি মূল ভিত্তি হিসাবে একটি ভেরিয়েবল ফ্রিকোয়েন্সি মোটর অসাধারণ দক্ষতা এবং নমনীয়তা প্রদান করে, যা ব্যাপক শিল্প অ্যাপ্লিকেশনের জন্য এটিকে আদর্শ করে তোলে...

আরও দেখুন

থ্রি ফেজ মোটর এবং সিঙ্গেল ফেজ মোটরের মধ্যে দক্ষতার পার্থক্য শিল্প মোটর নির্বাচনের ক্ষেত্রে সবচেয়ে গুরুত্বপূর্ণ বিবেচনার মধ্যে একটি। এই পার্থক্যগুলি বোঝা ইঞ্জিনিয়ার, সুবিধা পরিচালক এবং সরঞ্জাম ডিজাইনারদের জন্য সঠিক সিদ্ধান্ত নেওয়ায় সাহায্য করে...

আরও দেখুন

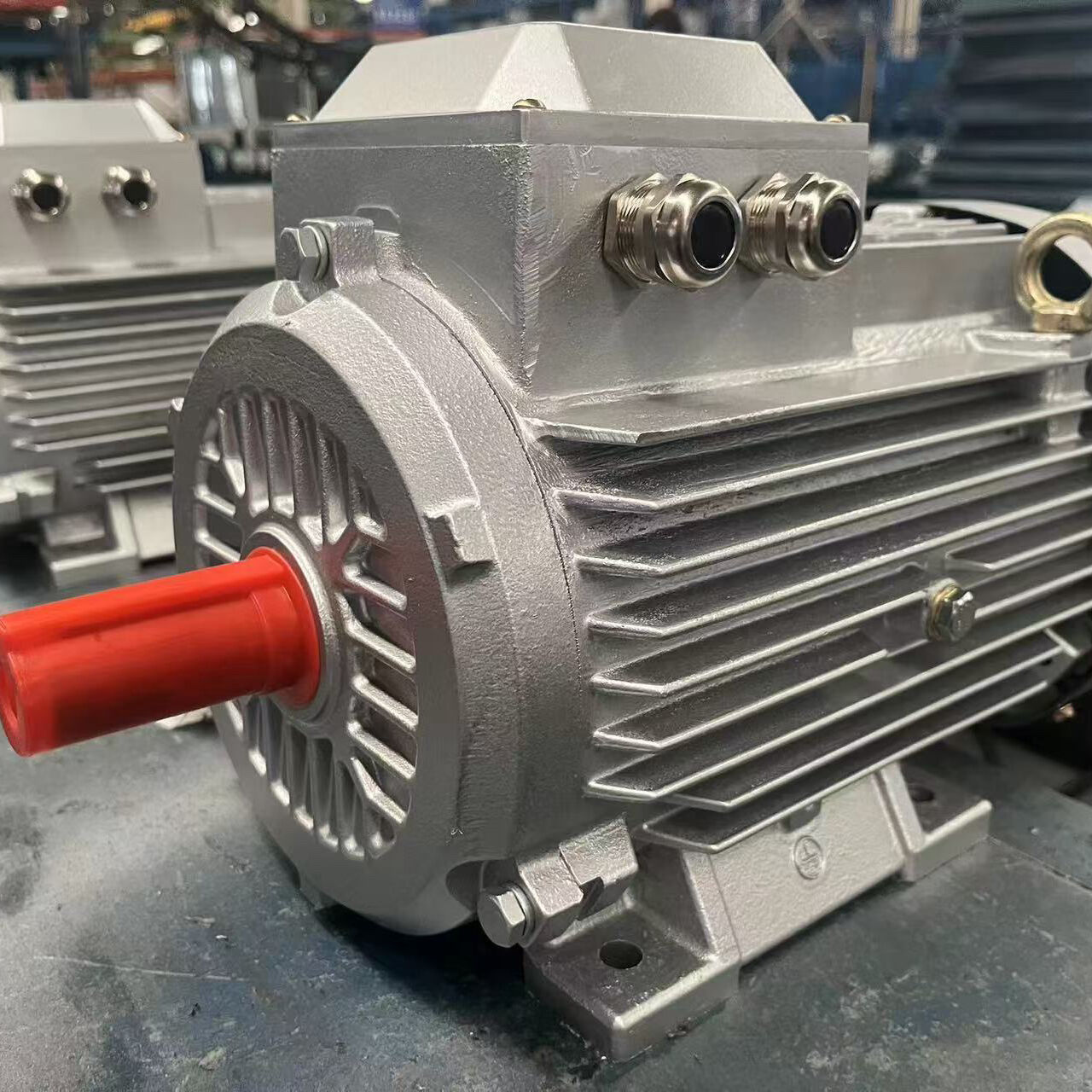

শিল্প সুবিধাগুলি গুরুত্বপূর্ণ সরঞ্জাম চালানোর এবং উৎপাদন দক্ষতা বজায় রাখার জন্য ভারী পরিমাণে থ্রি ফেজ মোটরের উপর নির্ভর করে। এই শক্তিশালী বৈদ্যুতিক মেশিনগুলি উৎপাদন ক্রিয়াকলাপের মেরুদণ্ড গঠন করে, কনভেয়ার সিস্টেম থেকে শুরু করে ভারী মেশিনারি পর্যন্ত সবকিছু চালনা করে...

আরও দেখুন

বিশ্বব্যাপী উৎপাদন কারখানাগুলি তাদের উৎপাদন ব্যবস্থার মূল ভিত্তি হিসাবে বৈদ্যুতিক মোটরগুলির উপর নির্ভর করে, এবং প্রকৌশলীরা এদের উন্নত কর্মক্ষমতার কারণে ধারাবাহিকভাবে থ্রি-ফেজ মোটর বেছে নেন। এই শক্তিশালী বৈদ্যুতিক যন্ত্রগুলি অত্যধিক...

আরও দেখুন

বিশ্বব্যাপী উৎপাদন কারখানাগুলি তাদের কার্যক্রম অনুকূল করতে, শক্তি খরচ কমাতে এবং মোট উৎপাদনশীলতা উন্নত করতে উন্নত মোটর প্রযুক্তির দিকে ক্রমবর্ধমানভাবে ঝুঁকছে। বিভিন্ন প্রকার মোটরগুলির মধ্যে, সিঙ্ক্রোনাস মোটরগুলি একটি...

আরও দেখুন

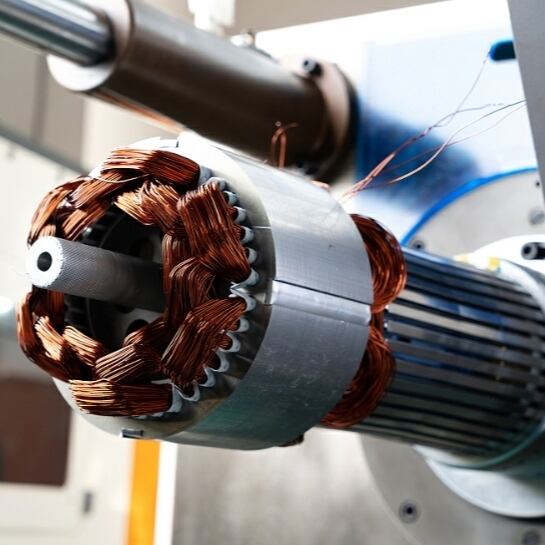

বৈদ্যুতিক মোটরের কর্মক্ষমতা অপ্টিমাইজ করার প্রয়োজনীয়তা চালিত করে, শিল্প সুবিধাগুলির জন্য শক্তি দক্ষতা বিশ্বব্যাপী একটি গুরুত্বপূর্ণ উদ্বেগ হয়ে উঠেছে। শিল্প অ্যাপ্লিকেশনের মেরুদণ্ড হিসাবে ব্যাপকভাবে স্বীকৃত, শিম কেজ মোটরগুলি উল্লেখযোগ্য পরিমাণে খরচ করে...

আরও দেখুন

শিল্প সরঞ্জামগুলির জন্য সঠিক স্কাইরেল কেজ মোটর নির্বাচন করা যান্ত্রিক সিস্টেম ডিজাইনের সবচেয়ে গুরুত্বপূর্ণ সিদ্ধান্তগুলির মধ্যে একটি। এই শক্তিশালী ইন্ডাকশন মোটরগুলি অসংখ্য অ্যাপ্লিকেশনের মেরুদণ্ড হিসেবে কাজ করে, উৎপাদন প্রক্রিয়া থেকে শুরু করে...

আরও দেখুন

কপিরাইট © 2026 চংকিং লিজাজান অটোমেশন টেকনোলজি কো., লিমিটেড। সমান্বিত অধিকার সংরক্ষিত। - গোপনীয়তা নীতি