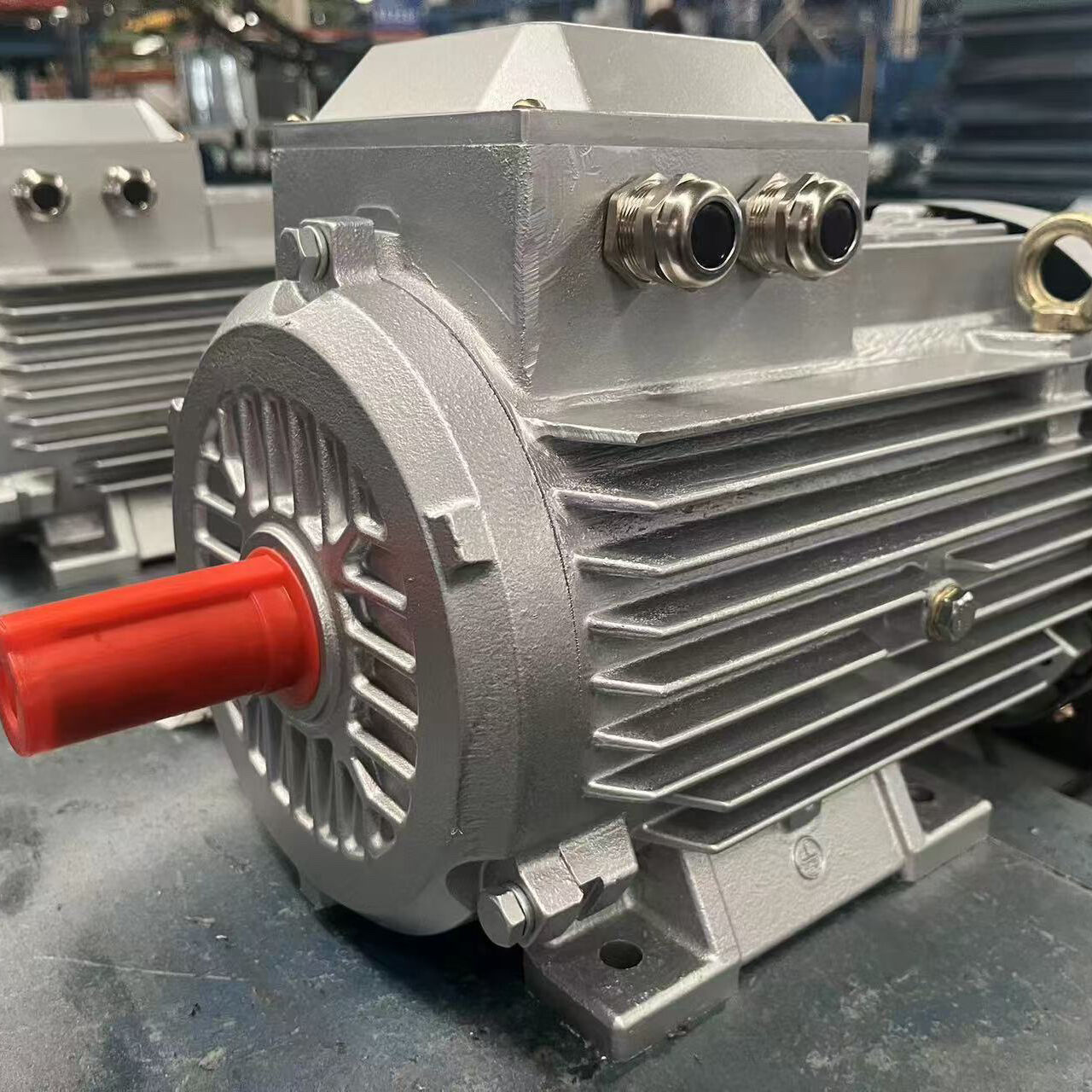

3 phase synchronous motor

A 3 phase synchronous motor is a sophisticated electrical machine that operates at a constant speed synchronized with the power supply frequency. This advanced motor consists of a stator with three-phase windings and a rotor with either permanent magnets or electromagnetic windings. The motor functions by creating a rotating magnetic field in the stator, which interacts with the rotor's magnetic field to produce continuous rotational motion. One of its defining characteristics is its ability to maintain exact synchronization with the supply frequency, regardless of load variations within its rated capacity. The motor's design incorporates advanced features such as precise speed control, high power factor correction capabilities, and excellent efficiency at rated loads. In industrial applications, 3 phase synchronous motors excel in driving heavy machinery, pumps, compressors, and conveyor systems where constant speed operation is crucial. These motors are particularly valuable in applications requiring high power output, typically ranging from several hundred to thousands of horsepower. Their ability to operate at leading power factors makes them instrumental in improving overall power system efficiency and reducing electrical operating costs in large industrial installations.