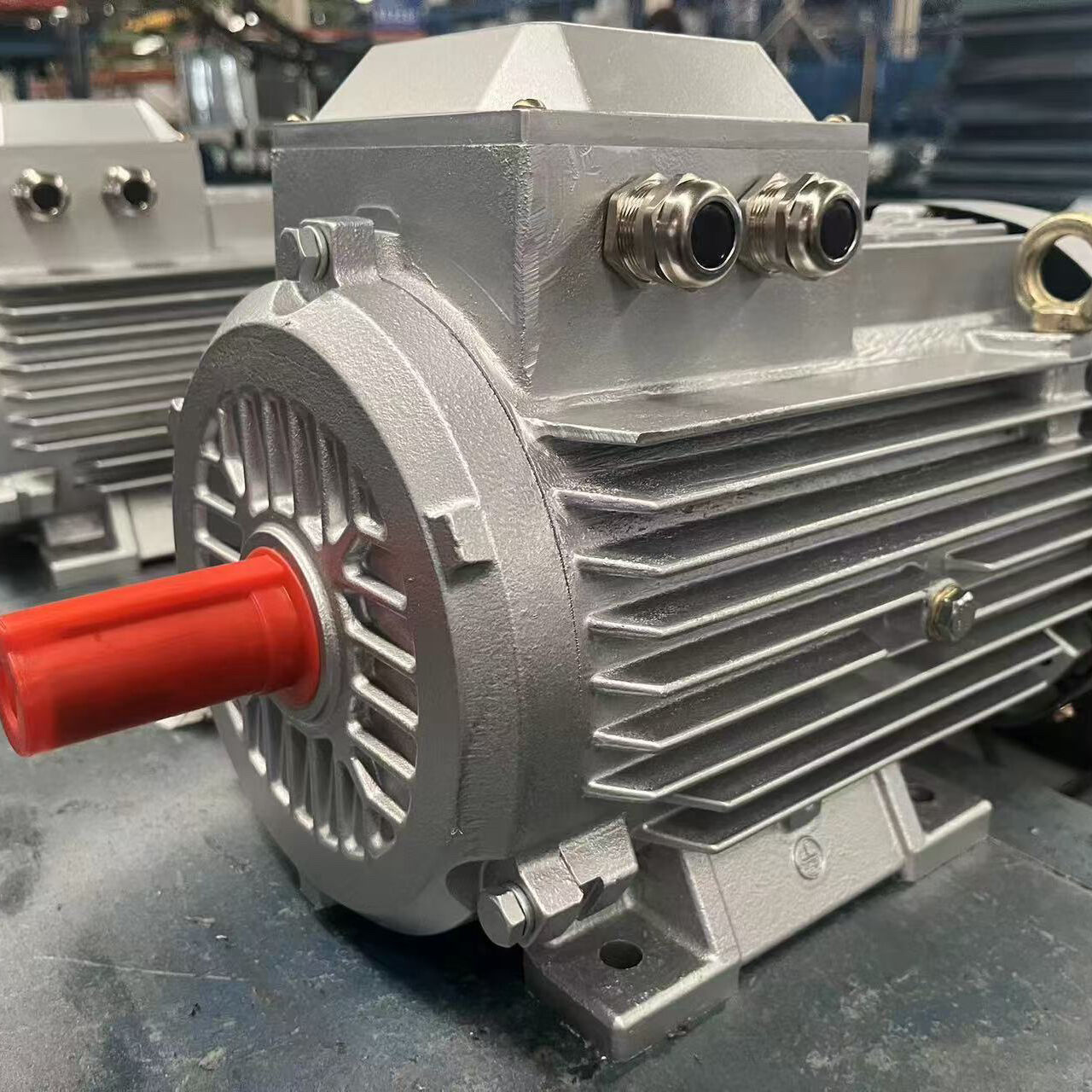

synchron servo motor

A synchron servo motor represents a sophisticated piece of electromechanical engineering that combines precise control with reliable performance. This advanced motor system operates by maintaining perfect synchronization between the rotor's mechanical speed and the magnetic field's electrical frequency, ensuring exact position control and consistent torque output. The motor incorporates feedback mechanisms, typically encoders or resolvers, that continuously monitor and adjust its position, speed, and torque. These motors excel in applications requiring precise motion control, offering exceptional accuracy down to fractions of a degree. They operate through a closed-loop control system that constantly compares the actual position with the commanded position, making immediate adjustments to maintain accuracy. The design typically features permanent magnets in the rotor and electronically controlled electromagnetic coils in the stator, enabling smooth, efficient operation across various speed ranges. Modern synchron servo motors often integrate advanced features such as thermal protection, multiple feedback options, and compatibility with various industrial communication protocols. They find extensive use in robotics, CNC machinery, automated manufacturing lines, and precision assembly equipment, where their combination of accuracy, reliability, and responsive control makes them indispensable.