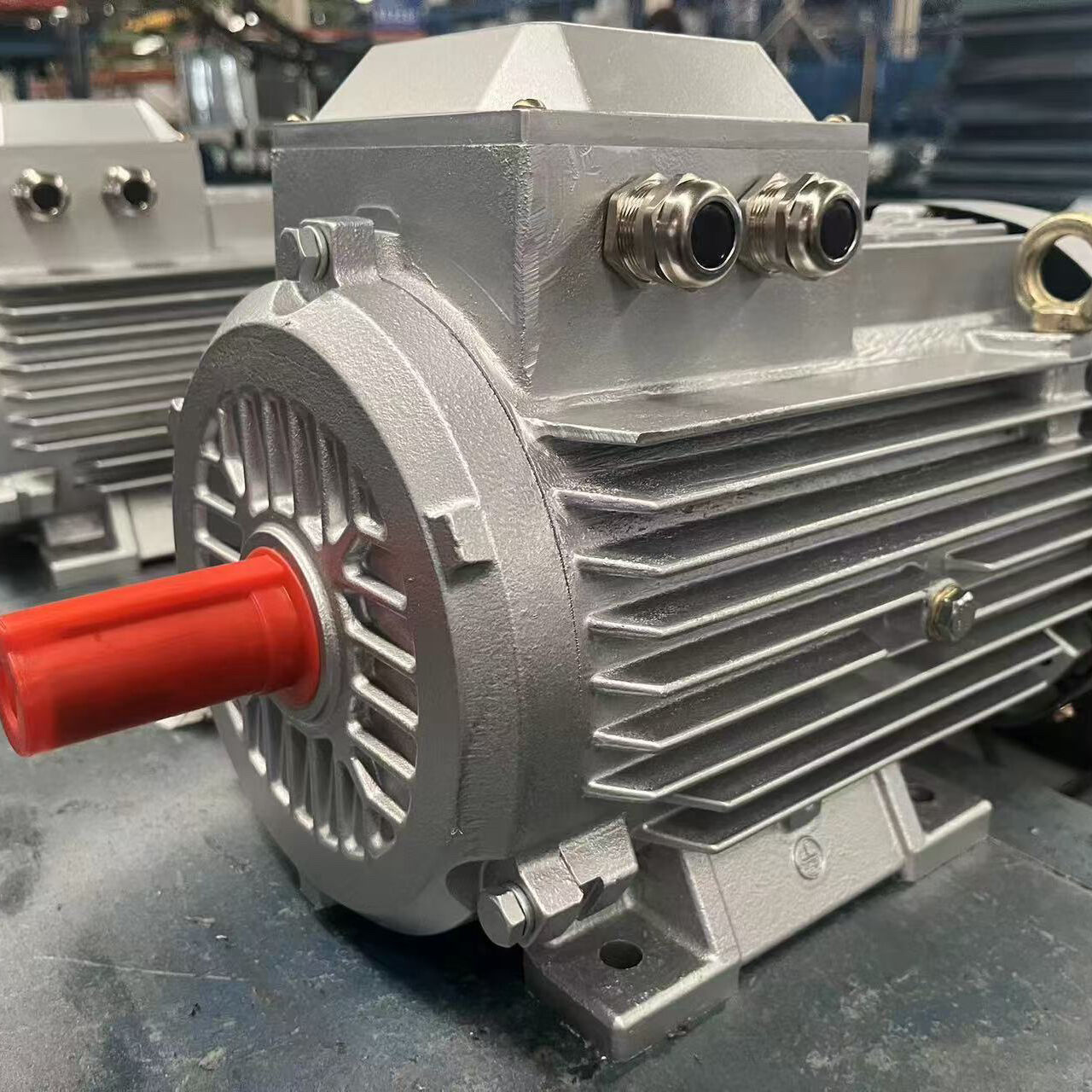

ac synchronous motor

An AC synchronous motor is a sophisticated electrical device that operates by synchronizing rotor rotation with the frequency of the supplied alternating current. This advanced motor consists of a stator containing windings that create a rotating magnetic field and a rotor equipped with either permanent magnets or electromagnets. The motor maintains constant speed regardless of load variations, making it ideal for applications requiring precise speed control. The rotor rotates at the same speed as the rotating magnetic field, which is determined by the frequency of the power supply and the number of magnetic poles in the motor. These motors excel in high-power industrial applications, offering superior efficiency and precise speed control. They are particularly valuable in manufacturing processes, large compressors, pumps, and conveyor systems where consistent speed is crucial. The motor's ability to maintain synchronous speed under varying loads, combined with its high power factor and efficiency ratings, makes it an essential component in modern industrial automation. Additionally, these motors can operate in both motoring and generating modes, providing flexibility in applications where energy recovery is beneficial.