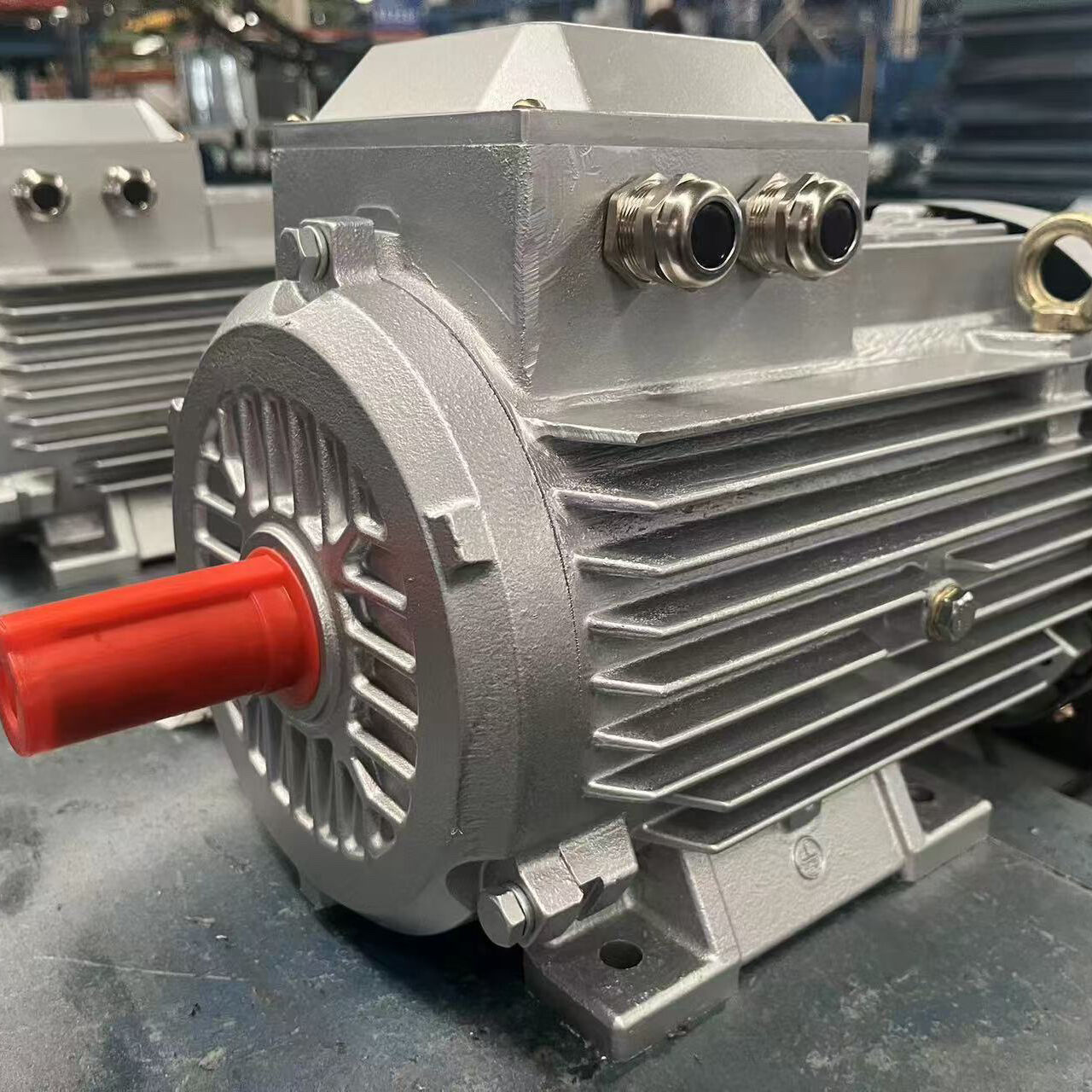

pmsm motor price

The PMSM motor price represents a significant consideration in the industrial automation and electric vehicle sectors. Permanent Magnet Synchronous Motors (PMSM) combine advanced technology with reliable performance, offering exceptional efficiency rates of up to 96%. These motors feature permanent magnets embedded in the rotor, creating a consistent magnetic field that contributes to precise speed control and optimal torque output. The price range typically varies from $200 to $2000, depending on power ratings, size specifications, and manufacturing quality. When evaluating PMSM motor prices, buyers must consider factors such as power output (ranging from 0.1kW to 100kW), operational voltage requirements, and specific application needs. The investment reflects the motor's sophisticated design, incorporating high-grade magnetic materials and precision engineering. Applications span across various industries, including electric vehicles, HVAC systems, industrial automation, and renewable energy systems. The price point often correlates with the motor's efficiency ratings, durability features, and advanced control capabilities, making it a cost-effective long-term investment for operations requiring precise motion control and energy efficiency.