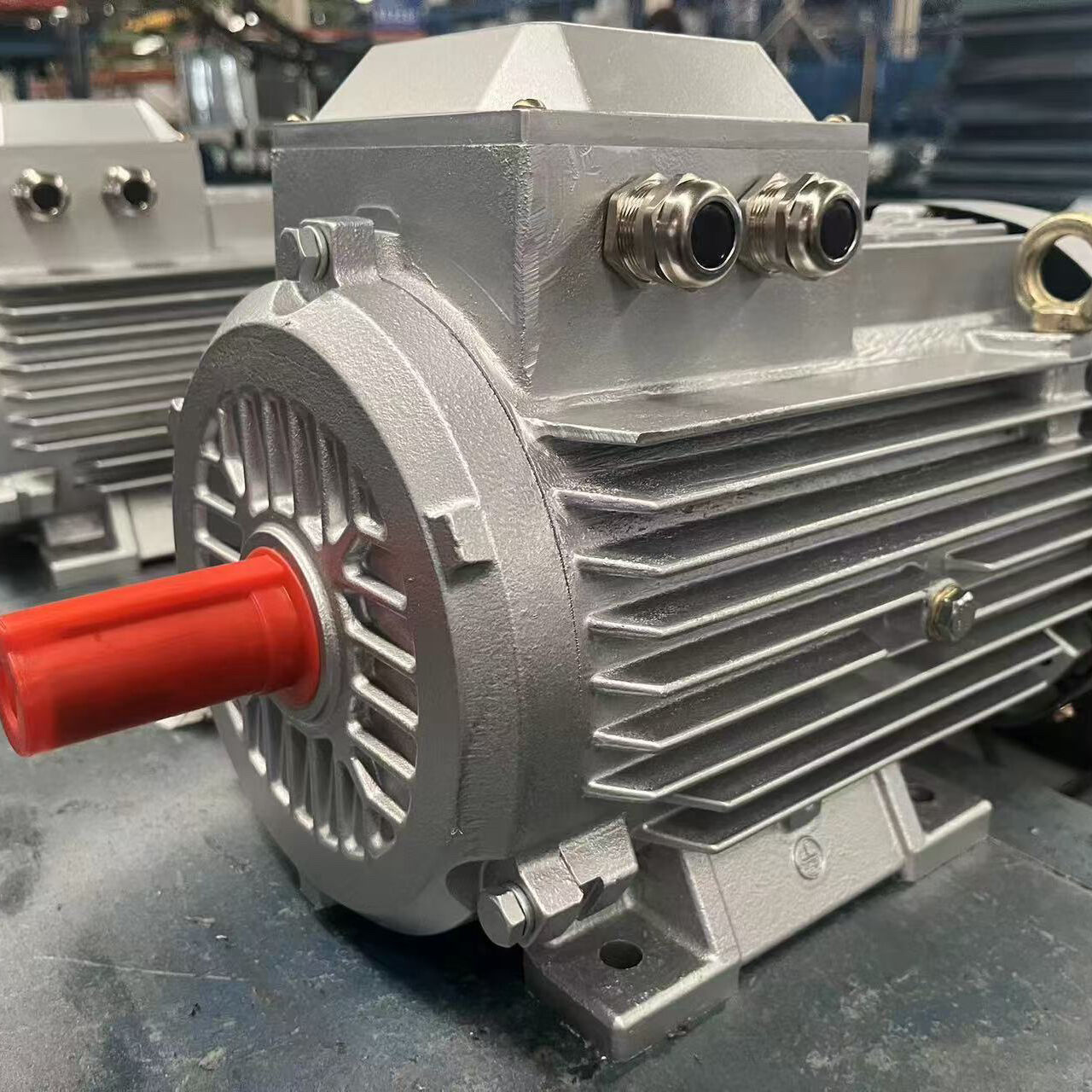

motor synchronous motor

A synchronous motor represents a sophisticated piece of electrical machinery that operates by maintaining perfect synchronization between the rotor's mechanical speed and the magnetic field's rotating speed in the stator. This advanced motor technology consists of a stator with a polyphase AC winding and a rotor equipped with either permanent magnets or DC-excited poles. The fundamental principle behind its operation involves the rotor field synchronizing precisely with the rotating magnetic field produced by the stator windings, resulting in constant speed operation regardless of load variations within its rated capacity. The motor's design enables it to maintain exact speed synchronization with the supply frequency, making it ideal for applications requiring precise speed control. In industrial settings, synchronous motors excel in high-power applications, typically ranging from several hundred kilowatts to multiple megawatts. These motors are extensively utilized in manufacturing processes, large compressors, pumps, mill drives, and other industrial applications where consistent speed and high efficiency are crucial. Modern synchronous motors often incorporate advanced control systems and power electronics, enabling sophisticated speed control and improved starting characteristics. Their ability to operate at leading power factors also makes them valuable for power factor correction in industrial electrical systems, contributing to overall system efficiency and reduced operating costs.