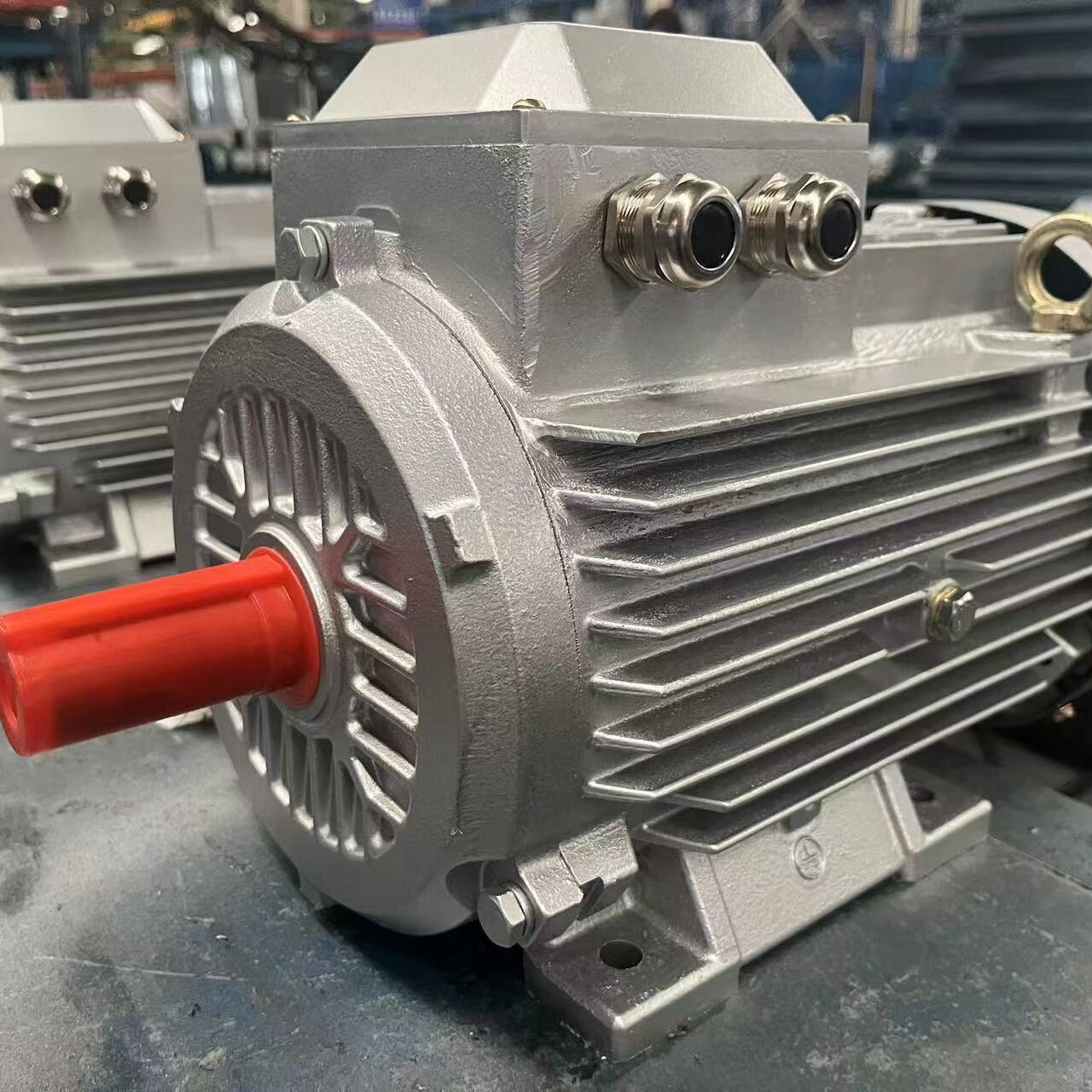

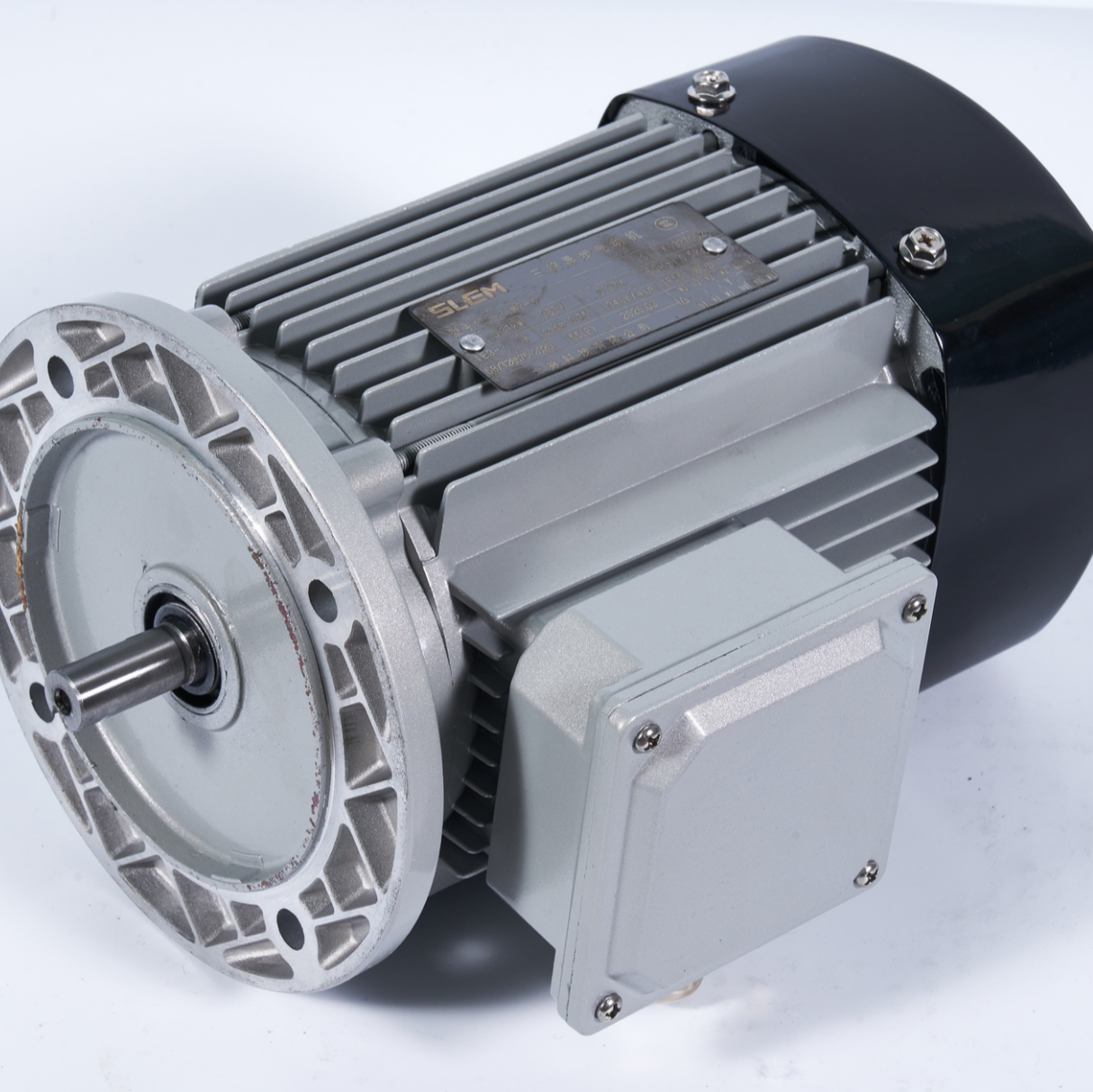

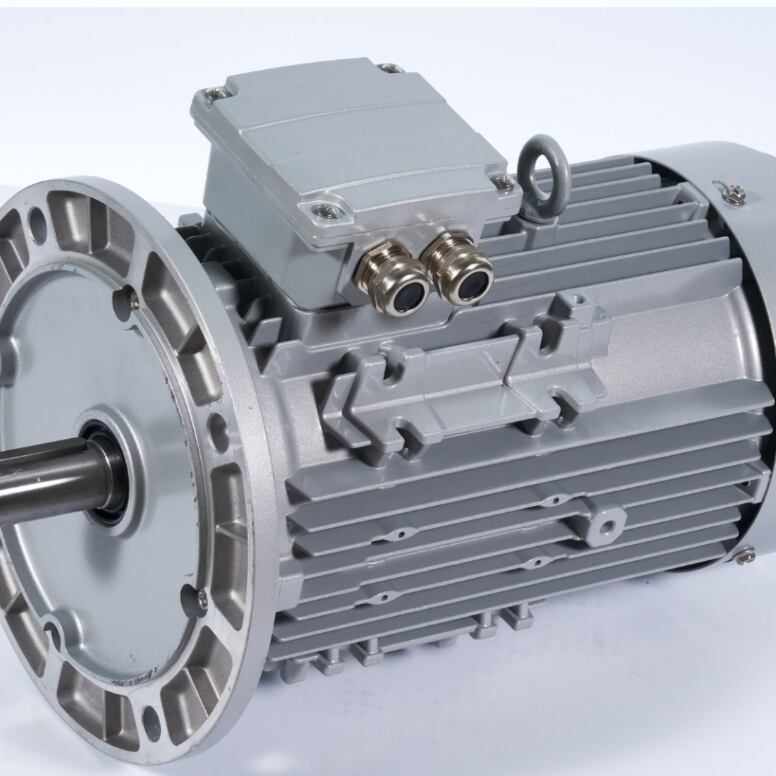

low rpm motor

A low RPM motor, also known as a low-speed motor, is an essential piece of machinery designed to operate efficiently at reduced rotational speeds. These motors typically run at speeds below 1000 RPM, making them ideal for applications requiring precise control and steady torque output. The technology behind low RPM motors incorporates advanced engineering principles to deliver consistent performance while maintaining energy efficiency. These motors feature robust construction with high-grade materials, ensuring durability and reliability in various operating conditions. The design typically includes enhanced bearing systems, specialized winding configurations, and optimized magnetic circuits to achieve smooth operation at lower speeds without sacrificing torque capacity. Low RPM motors find widespread use across multiple industries, from manufacturing and processing equipment to renewable energy systems. They are particularly valuable in applications such as conveyor systems, mixing equipment, and precision machinery where controlled, steady movement is crucial. The motors excel in situations requiring high torque at low speeds, eliminating the need for complex gear reduction systems in many cases. Modern low RPM motors often incorporate smart features like temperature monitoring, speed control capabilities, and protection against overload conditions, making them both versatile and reliable for long-term operation.