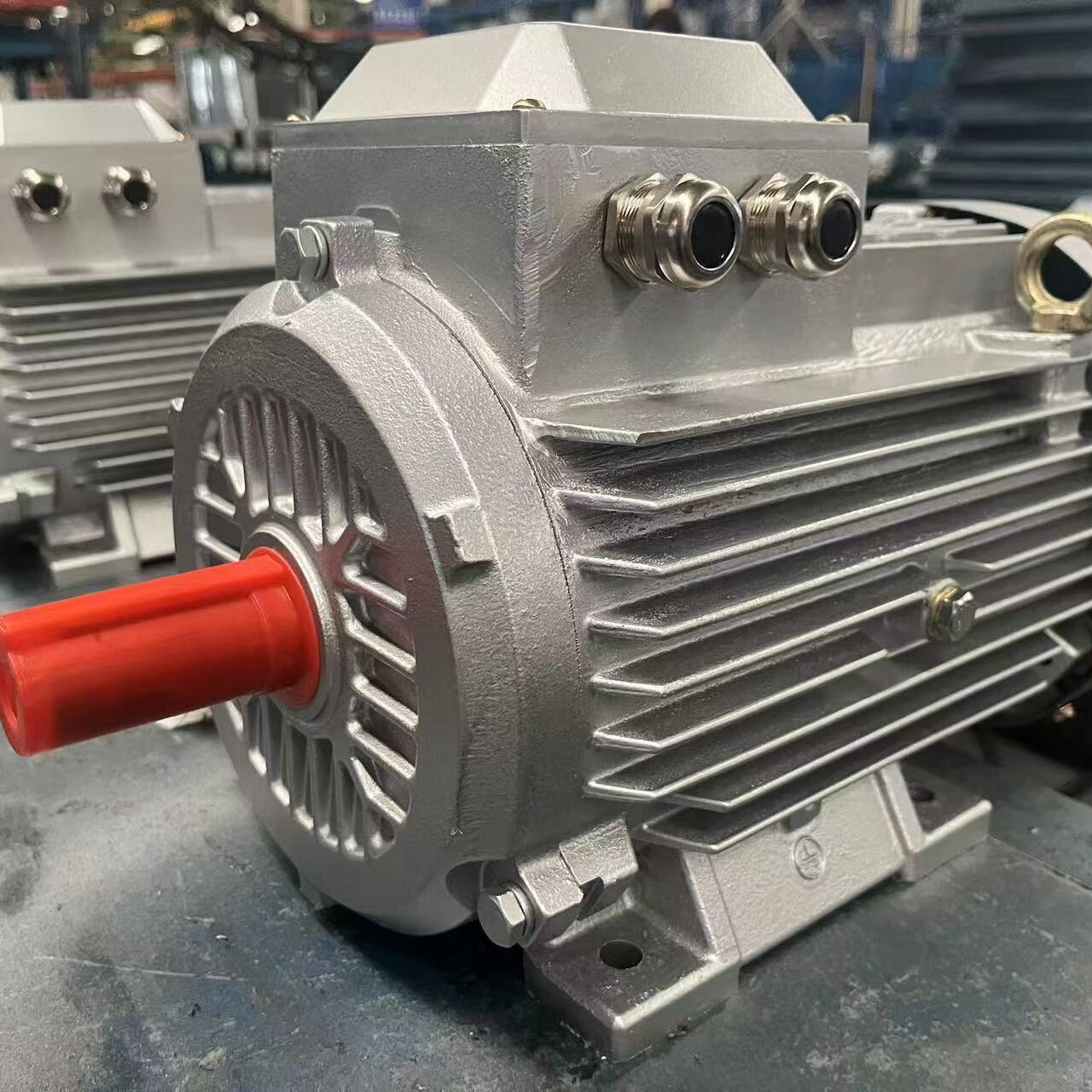

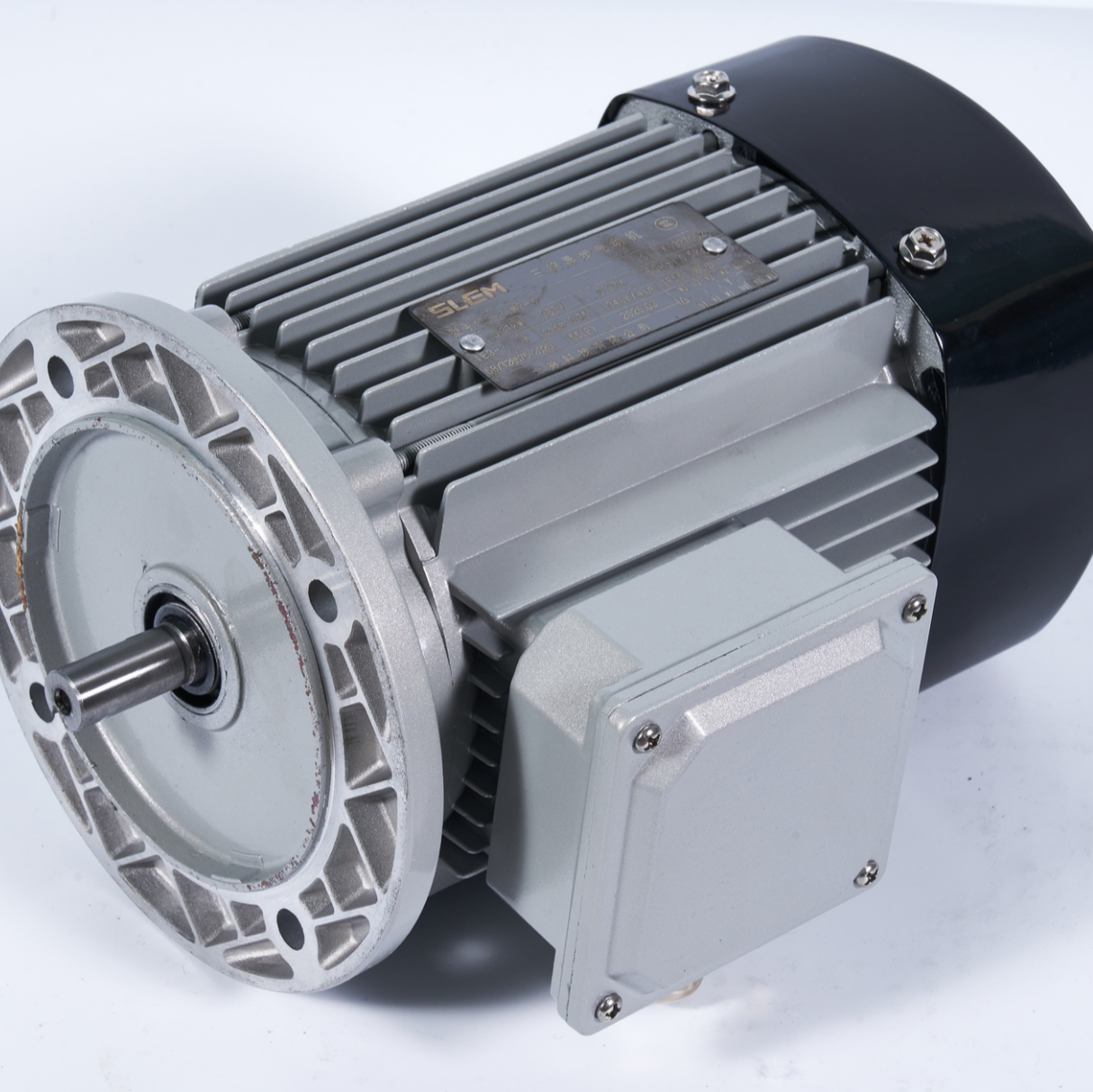

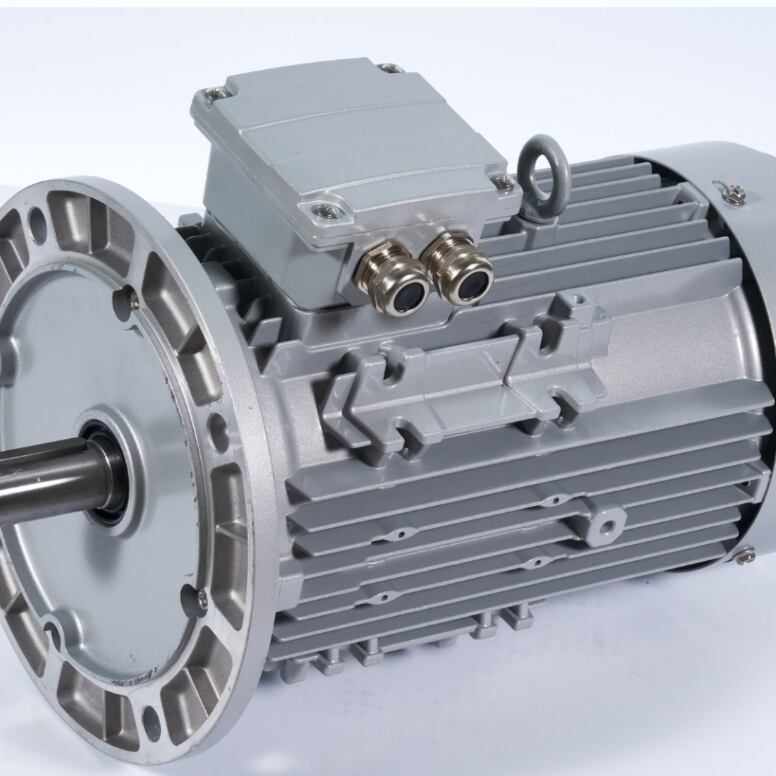

low speed motor

A low speed motor is a specialized electrical device engineered to deliver consistent power output at reduced rotational speeds. Operating typically between 10 to 500 RPM, these motors are distinguished by their ability to maintain high torque while running at slower velocities. The design incorporates advanced magnetic configurations and precise gear mechanisms to achieve optimal performance at lower speeds without sacrificing power delivery. These motors feature robust construction with enhanced bearing systems, specialized cooling mechanisms, and reinforced shaft designs to handle the increased torque demands. The technology employs sophisticated control systems that enable precise speed regulation and position control, making them ideal for applications requiring exact movement coordination. Low speed motors find extensive use across various industries, including manufacturing automation, conveyor systems, mixing equipment, and precision machinery. They are particularly valuable in processes where controlled movement and high torque are essential, such as in packaging lines, printing presses, and material handling systems. The motors special design considerations include thermal management systems, advanced lubrication methods, and protective features that ensure reliable operation under demanding conditions.