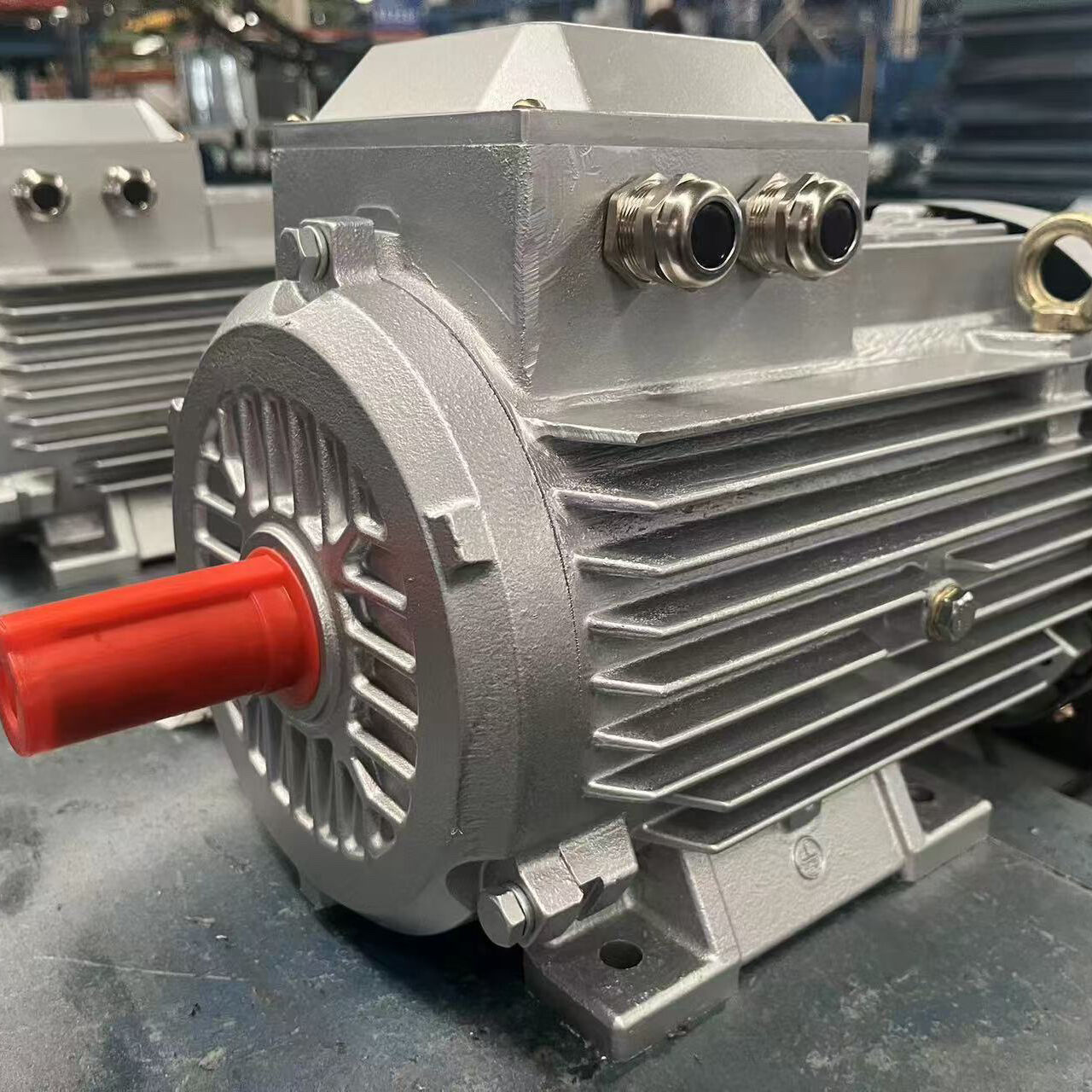

synchronous speed induction motor

A synchronous speed induction motor represents a sophisticated electrical machine that operates at a constant speed synchronized with the power supply frequency. This advanced motor combines the reliability of traditional induction motors with the precise speed control of synchronous motors. The rotor speed matches exactly with the rotating magnetic field produced by the stator, eliminating the characteristic slip found in conventional induction motors. These motors typically consist of a squirrel cage rotor design with additional features that enable synchronous operation. The motor starts as a regular induction motor and, once near synchronous speed, locks into step with the supply frequency. This technological marvel finds extensive applications in industrial processes requiring constant speed operation, such as conveyor systems, pumps, and precision manufacturing equipment. The motor's ability to maintain exact speed regardless of load variations within its rating makes it invaluable in applications where precise speed control is crucial. Modern designs incorporate advanced materials and construction techniques, ensuring high efficiency and reliability while minimizing maintenance requirements. The synchronous speed operation also contributes to improved power factor correction, making these motors increasingly popular in energy-conscious industrial applications.