servo motor control system

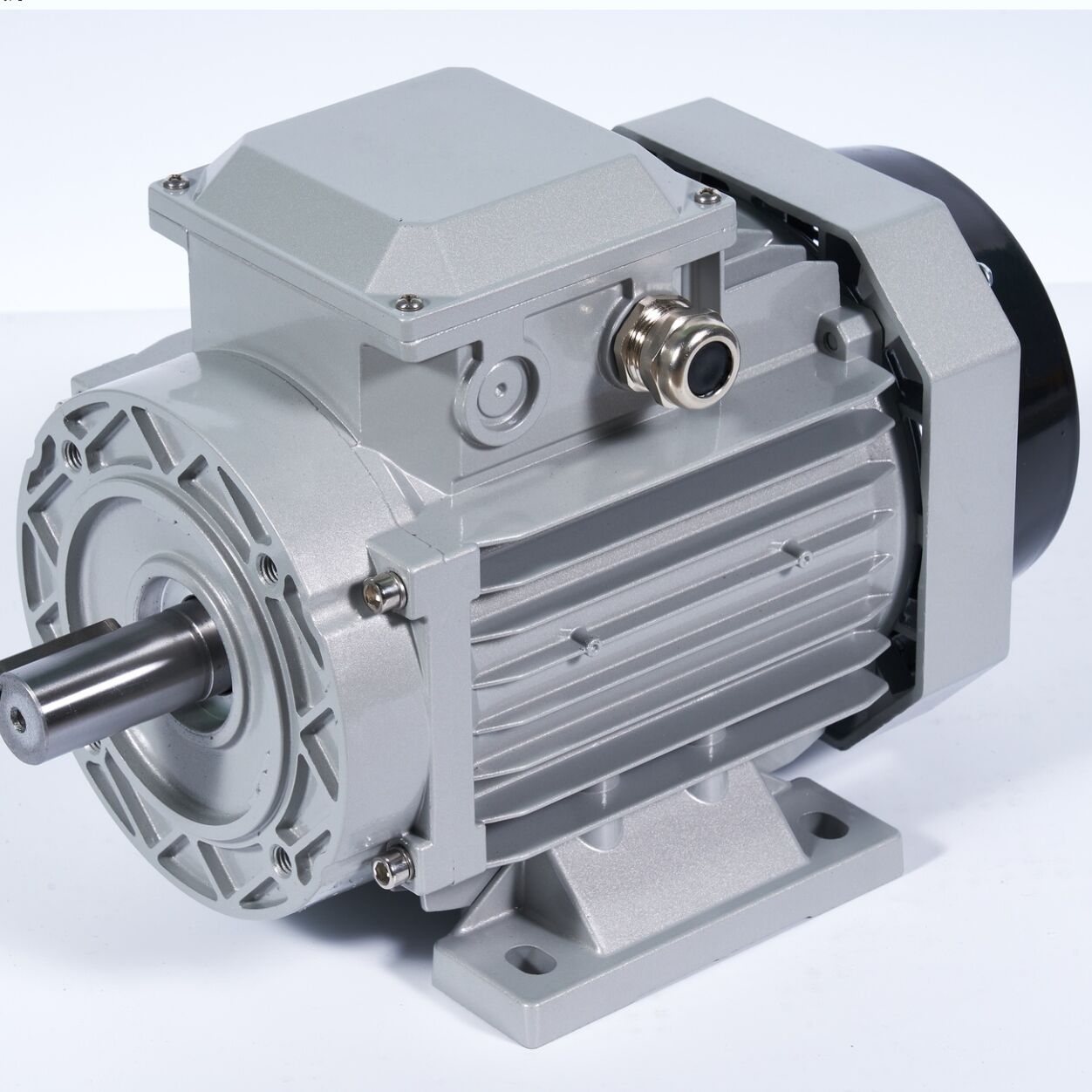

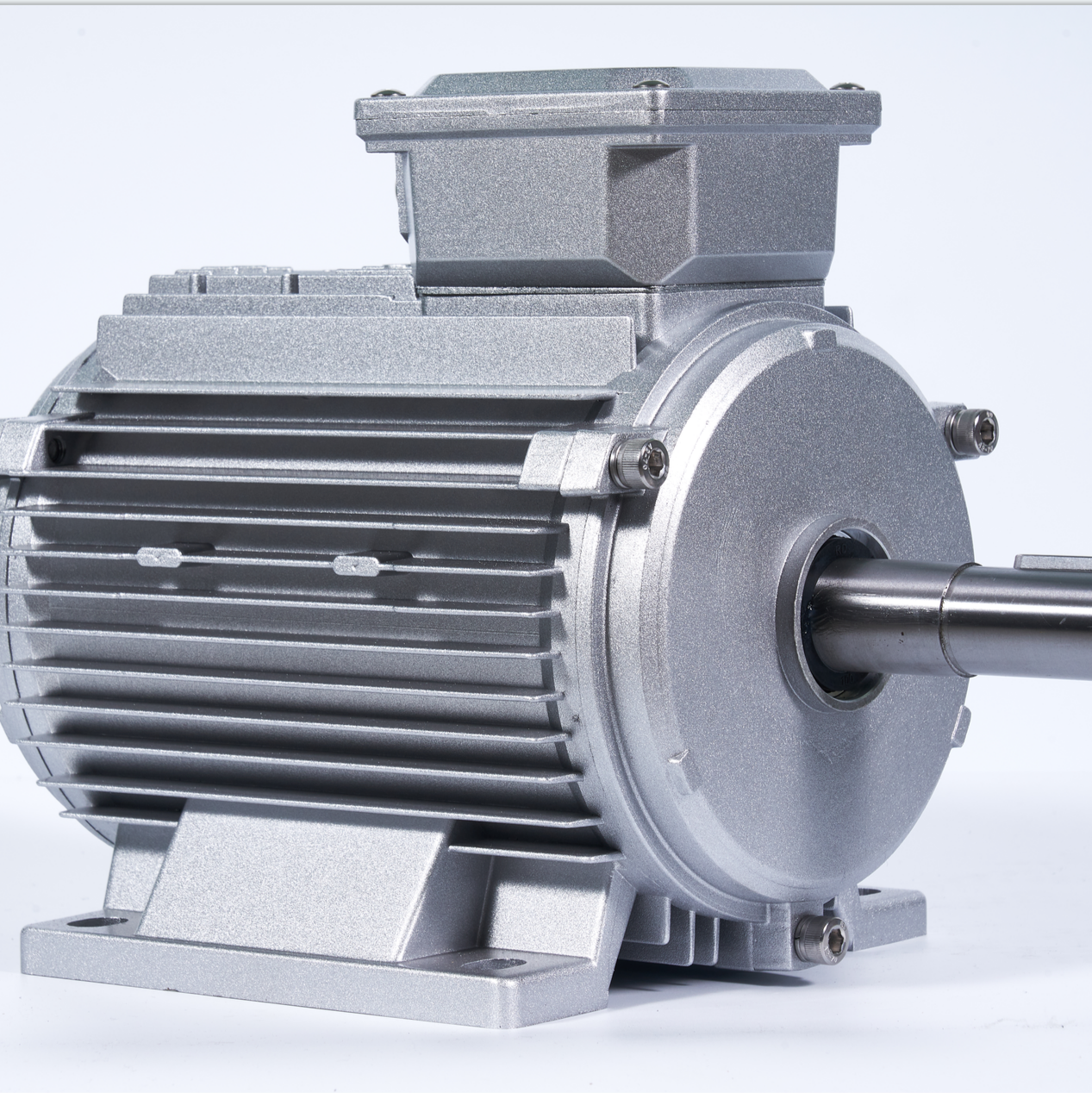

A servo motor control system represents a sophisticated motion control solution that integrates precision positioning with dynamic response capabilities. This advanced system consists of a motor, encoder, controller, and driver working in harmony to achieve accurate position, velocity, and acceleration control. The system operates through a closed-loop feedback mechanism where the encoder continuously monitors the motor's actual position and feeds this information back to the controller. The controller then compares this data with the desired position and makes instantaneous adjustments to maintain precise control. With capabilities ranging from sub-degree positioning accuracy to high-speed synchronized motion, servo motor control systems are essential in modern automation. These systems excel in applications requiring rapid position changes, consistent speed regulation, and precise torque control. They are widely deployed in industrial robotics, CNC machinery, automated manufacturing lines, and precision equipment where exact positioning and smooth motion profiles are crucial. The system's ability to handle variable loads while maintaining accuracy makes it indispensable in advanced manufacturing processes, packaging systems, and high-precision assembly operations.