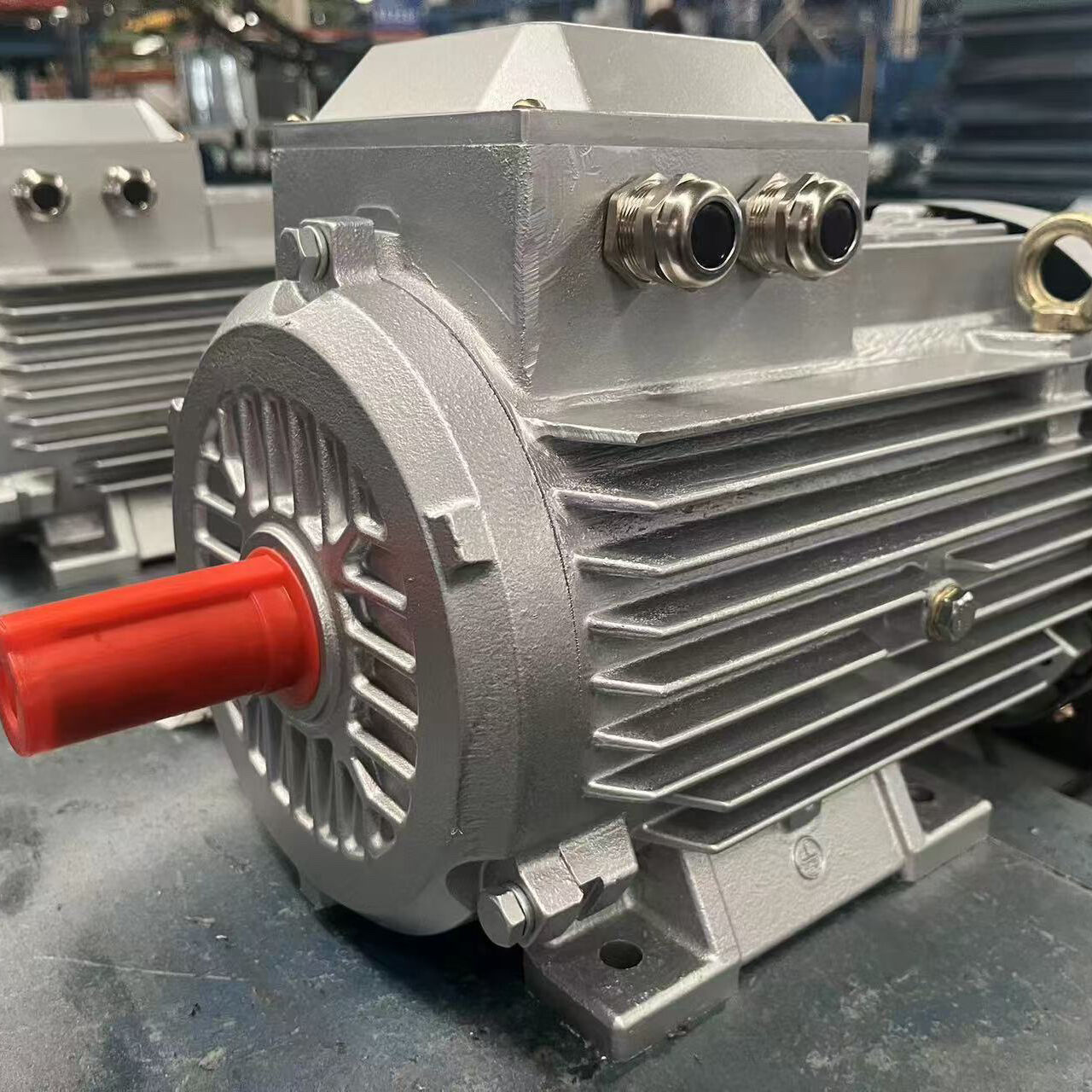

sync motor

A synchronous motor, commonly known as a sync motor, is an advanced electrical machine that operates by maintaining precise speed synchronization with the frequency of its power supply. This sophisticated device consists of a stator that generates a rotating magnetic field and a rotor that turns at the same speed as the field, ensuring perfect synchronization. The motor's ability to maintain constant speed regardless of load variations makes it invaluable in numerous industrial applications. Sync motors excel in applications requiring precise speed control, such as industrial manufacturing, conveyor systems, and processing equipment. The technology behind sync motors incorporates advanced electromagnetic principles, utilizing either permanent magnets or electromagnetic windings to create the necessary magnetic fields. Modern sync motors often feature enhanced control systems, allowing for variable speed operation through frequency converters and sophisticated feedback mechanisms. These motors are available in various power ratings, from fractional horsepower units to large industrial machines capable of delivering thousands of horsepower. Their design incorporates robust bearing systems, thermal management features, and protective enclosures to ensure reliable operation in demanding environments.