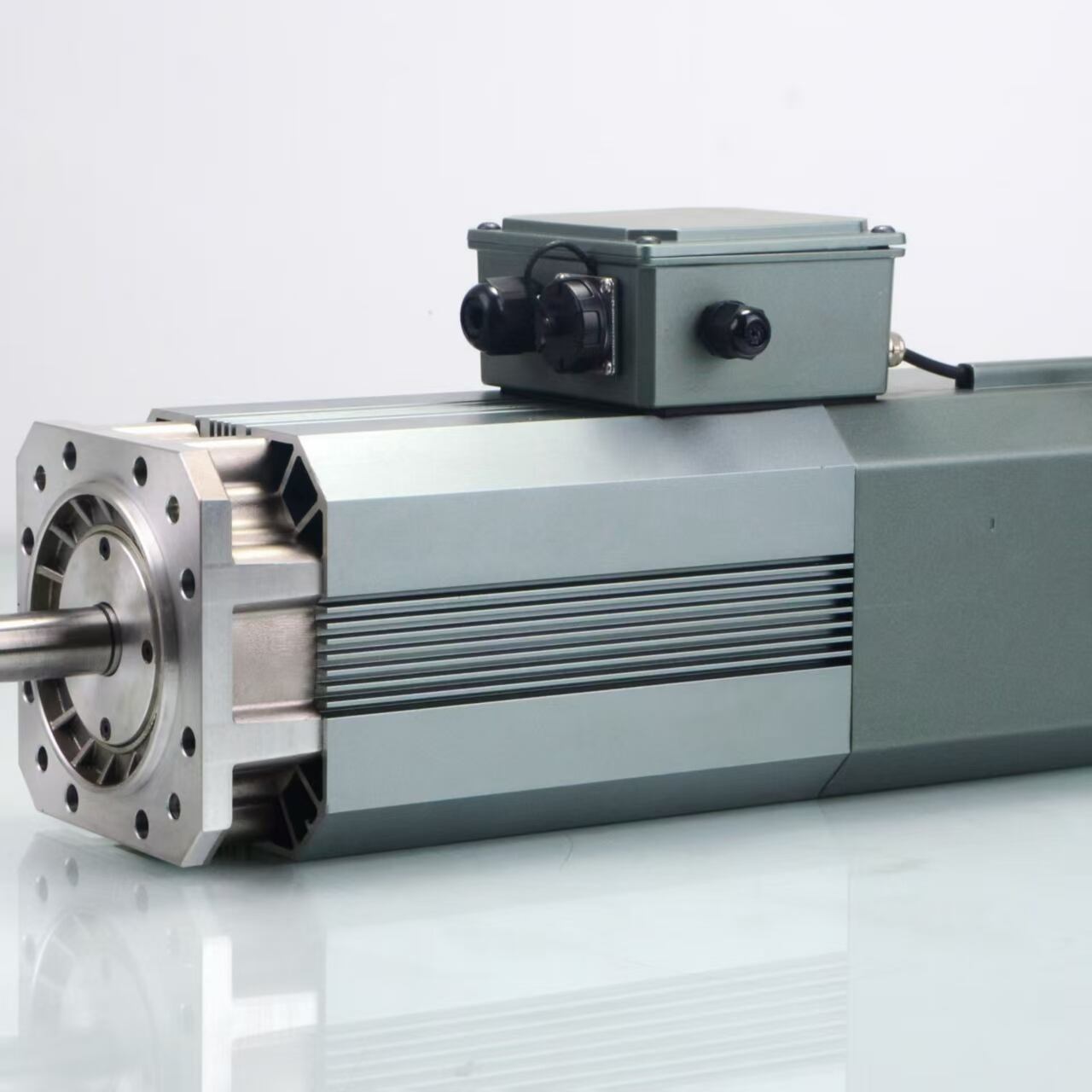

Manufacturing facilities worldwide rely on electric motors as the backbone of their production systems, and engineers consistently choose three phase motors for their superior performance characteristics. These robust electrical machines deliver exceptional efficiency, reliability, and power output that single-phase alternatives simply cannot match in demanding industrial environments. The widespread adoption of three phase motors in manufacturing stems from their ability to provide smooth, continuous torque while minimizing electrical losses and maintenance requirements.

Superior Power Delivery and Efficiency

Balanced Power Distribution

Three phase motors excel in manufacturing applications because they distribute electrical load evenly across three separate phases, creating a balanced and stable power system. This configuration eliminates the power fluctuations common in single-phase systems, resulting in smoother operation and reduced vibration. The balanced power distribution also means that three phase motors can deliver approximately 50% more power than equivalent single-phase motors using the same amount of conductor material.

Engineers appreciate how this balanced approach reduces stress on both the motor windings and the electrical infrastructure. The constant power delivery characteristic of three phase systems means that manufacturing equipment experiences less mechanical stress, leading to longer equipment life and reduced maintenance costs. This reliability factor becomes crucial in continuous production environments where unexpected downtime can cost thousands of dollars per hour.

Energy Efficiency Advantages

Manufacturing facilities face increasing pressure to reduce energy consumption and operational costs, making the efficiency of three phase motors a compelling advantage. These motors typically achieve efficiency ratings between 85% and 95%, significantly higher than single-phase counterparts. The improved efficiency translates directly into lower electricity bills and reduced environmental impact, aligning with corporate sustainability goals.

The energy savings become more pronounced in high-power applications common in manufacturing. A 50-horsepower three phase motor can save thousands of dollars annually in electricity costs compared to less efficient alternatives. Additionally, the reduced energy consumption generates less heat, which decreases cooling requirements and further enhances overall system efficiency.

Starting Characteristics and Control Flexibility

Self-Starting Capability

One of the most significant advantages that engineers value in three phase motors is their inherent self-starting ability under load conditions. Unlike single-phase motors that often require starting capacitors or auxiliary windings, three phase motors generate a rotating magnetic field immediately upon energization. This characteristic eliminates the need for complex starting circuits and reduces the number of components that could potentially fail.

The self-starting feature proves invaluable in manufacturing applications where motors must frequently start and stop or restart automatically after power interruptions. Production lines equipped with three phase motors can resume operation quickly after brief power outages, minimizing production delays and maintaining operational efficiency.

Variable Speed Control Options

Modern manufacturing processes often require precise speed control to optimize production quality and efficiency. Three phase motors integrate seamlessly with variable frequency drives (VFDs) and other speed control systems, providing engineers with exceptional flexibility in process control. This compatibility allows for smooth acceleration and deceleration profiles that protect both the motor and driven equipment from mechanical stress.

The ability to vary motor speed precisely enables manufacturing systems to adapt to different production requirements without changing mechanical components. Engineers can optimize conveyor speeds, pump flows, and fan operations to match specific process needs, resulting in improved product quality and reduced energy consumption. This flexibility becomes increasingly important as manufacturers embrace Industry 4.0 concepts and smart manufacturing technologies.

Mechanical Advantages in Industrial Applications

Torque Characteristics and Performance

Three phase motors deliver superior torque characteristics that make them ideal for heavy-duty manufacturing applications. The constant instantaneous torque provided by the three-phase configuration eliminates the torque pulsations found in single-phase systems, resulting in smoother operation and reduced wear on mechanical components. This smooth torque delivery proves essential in precision manufacturing processes where vibration and mechanical disturbances must be minimized.

The high starting torque capability of three phase motors enables them to overcome static friction and accelerate heavy loads efficiently. Manufacturing equipment such as conveyor systems, heavy-duty mixers, and large pumps benefit from this characteristic, as they can start reliably even when fully loaded. Engineers value this reliability because it reduces the risk of production interruptions and eliminates the need for complex mechanical starting aids.

Size and Weight Considerations

Space constraints in manufacturing facilities make the compact size of three phase motors a significant advantage. These motors achieve higher power densities than single-phase alternatives, meaning they can deliver more horsepower in a smaller package. This space efficiency allows engineers to design more compact machinery and optimize factory floor layouts for improved workflow and accessibility.

The reduced weight of three phase motors also simplifies installation and maintenance procedures. Lighter motors require less robust mounting structures and are easier to handle during replacement or service operations. This weight advantage becomes particularly important in applications where motors must be mounted in elevated positions or integrated into mobile equipment.

Cost-Effectiveness and Economic Benefits

Initial Investment and Installation Costs

While three phase motors may have higher initial purchase costs compared to single-phase alternatives, engineers recognize that the total cost of ownership strongly favors three-phase systems in manufacturing applications. The elimination of starting components reduces both initial costs and future maintenance expenses. Additionally, the simpler control circuits required for three phase motors often offset any premium in motor pricing.

Installation costs for three phase motors are typically lower due to their straightforward wiring requirements and reduced need for auxiliary components. The absence of starting capacitors, centrifugal switches, and other single-phase motor components simplifies installation procedures and reduces the likelihood of wiring errors. This simplification translates to faster installation times and lower labor costs for manufacturing facility upgrades.

Long-Term Operational Savings

The operational savings associated with three phase motors accumulate significantly over their service life in manufacturing environments. Reduced maintenance requirements, higher efficiency, and improved reliability combine to create substantial cost savings. Manufacturing facilities typically experience 20-30% lower maintenance costs when using three phase motors compared to single-phase alternatives in equivalent applications.

The extended service life of three phase motors further enhances their economic advantage. The balanced electrical and mechanical loading reduces stress on motor components, often resulting in service lives that exceed 20 years in properly maintained manufacturing environments. This longevity allows engineers to amortize motor costs over longer periods while maintaining consistent production capabilities.

Integration with Modern Manufacturing Systems

Automation and Control System Compatibility

Today's manufacturing environments increasingly rely on sophisticated automation systems that require precise motor control and feedback capabilities. Three phase motors integrate seamlessly with programmable logic controllers (PLCs), distributed control systems (DCS), and other industrial automation platforms. This compatibility enables engineers to implement advanced control strategies that optimize production efficiency and quality.

The standardized nature of three phase motor control interfaces simplifies integration with existing manufacturing systems. Engineers can easily incorporate these motors into established control architectures without extensive modification or custom interface development. This standardization reduces implementation time and costs while ensuring reliable operation within complex automated production lines.

Predictive Maintenance and Monitoring

Modern manufacturing facilities implement predictive maintenance strategies to minimize unplanned downtime and optimize maintenance resources. Three phase motors support advanced monitoring techniques such as vibration analysis, thermal imaging, and motor current signature analysis. These diagnostic capabilities enable maintenance teams to identify potential issues before they result in equipment failures.

The balanced operation of three phase motors makes them excellent candidates for condition monitoring systems. Anomalies in electrical parameters, vibration patterns, or thermal signatures become more apparent against the stable baseline characteristics of properly functioning three phase motors. This enhanced diagnostic capability helps manufacturing facilities transition from reactive to proactive maintenance strategies, reducing overall maintenance costs and improving equipment availability.

FAQ

What makes three phase motors more efficient than single-phase motors in manufacturing applications?

Three phase motors achieve higher efficiency through their balanced power distribution system, which eliminates the power fluctuations present in single-phase motors. The constant power delivery and reduced electrical losses result in efficiency ratings typically 10-15% higher than equivalent single-phase motors. Additionally, three phase motors require fewer auxiliary components, reducing overall system losses and improving operational efficiency in manufacturing environments.

Can existing manufacturing facilities easily upgrade from single-phase to three-phase motor systems?

Most manufacturing facilities can upgrade to three-phase motor systems, though the complexity depends on existing electrical infrastructure. Facilities with three-phase power service can implement upgrades relatively easily by replacing motors and modifying control circuits. However, facilities currently operating on single-phase power may require electrical service upgrades, which should be evaluated by qualified electrical engineers to determine cost-effectiveness and implementation requirements.

How do three phase motors improve manufacturing process control and automation capabilities?

Three phase motors offer superior process control through their compatibility with variable frequency drives and advanced control systems. The smooth torque delivery and precise speed control capabilities enable manufacturing processes to maintain consistent product quality and adapt to varying production requirements. The inherent stability of three-phase systems also reduces electrical noise that could interfere with sensitive control and monitoring equipment used in modern automated manufacturing systems.

What maintenance advantages do three phase motors provide in industrial manufacturing environments?

Three phase motors require significantly less maintenance than single-phase alternatives due to their simpler construction and balanced operation. The absence of starting components like capacitors and centrifugal switches eliminates common failure points, while the smooth electrical and mechanical operation reduces wear on bearings and other mechanical components. This results in longer service intervals, reduced maintenance costs, and improved equipment availability in demanding manufacturing applications.

Table of Contents

- Superior Power Delivery and Efficiency

- Starting Characteristics and Control Flexibility

- Mechanical Advantages in Industrial Applications

- Cost-Effectiveness and Economic Benefits

- Integration with Modern Manufacturing Systems

-

FAQ

- What makes three phase motors more efficient than single-phase motors in manufacturing applications?

- Can existing manufacturing facilities easily upgrade from single-phase to three-phase motor systems?

- How do three phase motors improve manufacturing process control and automation capabilities?

- What maintenance advantages do three phase motors provide in industrial manufacturing environments?