Energy efficiency has become a critical concern for industrial facilities worldwide, driving the need to optimize electrical motor performance. Squirrel cage motors, widely recognized as the backbone of industrial applications, consume significant amounts of electrical energy across manufacturing plants, HVAC systems, and material handling equipment. Understanding how to maximize their efficiency not only reduces operational costs but also contributes to environmental sustainability goals. Modern industrial facilities are increasingly focused on implementing energy-saving strategies that deliver measurable returns on investment while maintaining reliable operation.

The demand for energy-efficient motor solutions continues to grow as organizations face rising electricity costs and stricter environmental regulations. Squirrel cage motors offer inherent advantages including robust construction, minimal maintenance requirements, and excellent reliability under varying load conditions. However, their energy consumption patterns can be significantly optimized through proper selection, installation, and operational practices. This comprehensive approach to motor efficiency encompasses everything from initial design considerations to ongoing maintenance protocols that ensure peak performance throughout the motor's operational lifespan.

Understanding Squirrel Cage Motor Fundamentals

Construction and Operating Principles

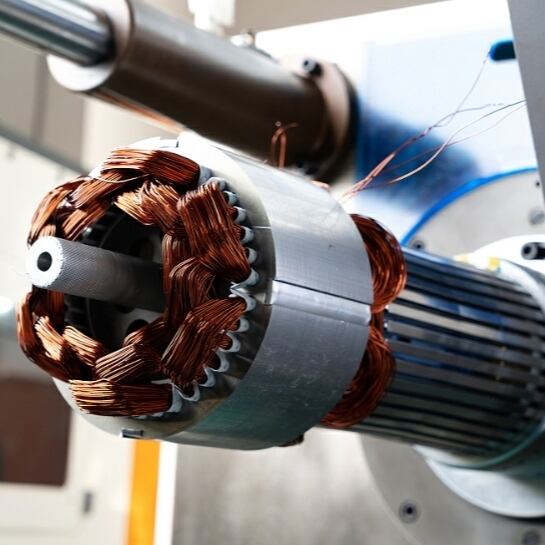

Squirrel cage motors derive their name from the distinctive rotor construction that resembles a squirrel exercise wheel. The rotor consists of aluminum or copper bars embedded in slots around the rotor core, connected by end rings that complete the electrical circuit. This simple yet effective design eliminates the need for slip rings or brushes, resulting in lower maintenance requirements and improved reliability compared to other motor types. The electromagnetic interaction between the stator's rotating magnetic field and the rotor's induced currents creates the torque necessary for mechanical operation.

The efficiency characteristics of these motors depend heavily on the quality of materials used in construction and the precision of manufacturing tolerances. Higher-grade electrical steel in the stator and rotor cores reduces magnetic losses, while optimized slot geometries minimize both electrical and mechanical losses. Modern manufacturing techniques allow for tighter air gaps between rotor and stator, which improves magnetic coupling and reduces the magnetizing current required for operation. These design improvements directly translate to enhanced energy efficiency and reduced operating temperatures.

Efficiency Classifications and Standards

International efficiency standards such as IE1, IE2, IE3, and IE4 provide clear benchmarks for motor performance evaluation. Standard efficiency motors (IE1) represent the baseline, while premium efficiency units (IE3) and super premium efficiency models (IE4) offer significantly improved performance characteristics. The efficiency improvements typically range from 2-8% between classifications, which may seem modest but translate to substantial energy savings over the motor's operational lifetime. Understanding these classifications helps facility managers make informed decisions about motor replacement and upgrade strategies.

The efficiency ratings are measured under standardized test conditions, but real-world performance can vary based on load factors, power quality, and environmental conditions. Motors operating at partial loads often experience reduced efficiency, making proper sizing crucial for optimal performance. Variable frequency drives can help maintain efficiency across different operating points, but their installation must be carefully planned to avoid introducing harmonic distortions that could negatively impact overall system efficiency.

Motor Selection and Sizing Strategies

Load Analysis and Proper Sizing

Accurate load analysis forms the foundation of efficient motor selection, requiring detailed understanding of the driven equipment's operational requirements. Oversized motors operate at reduced efficiency due to lower power factors and increased magnetic losses, while undersized units may experience premature failure due to excessive heating and stress. The optimal sizing typically involves selecting a motor that operates between 75-100% of its rated capacity during normal operation. This range ensures good efficiency while providing adequate reserve capacity for occasional peak demands or varying load conditions.

Load profiling involves analyzing the actual operating patterns throughout different production cycles, seasonal variations, and process requirements. Many facilities discover that their existing motors are significantly oversized, presenting immediate opportunities for efficiency improvements through rightsizing during replacement cycles. Modern monitoring systems can provide detailed load data that supports accurate sizing decisions, eliminating the traditional practice of applying excessive safety factors that lead to chronic motor underloading and reduced efficiency.

Environmental and Application Considerations

Environmental factors significantly influence motor efficiency and longevity, requiring careful consideration during the selection process. Temperature extremes, humidity levels, altitude, and atmospheric contamination all affect motor performance and efficiency characteristics. Motors operating in high-temperature environments may require derating or specialized cooling systems to maintain optimal efficiency levels. Similarly, high-altitude installations experience reduced air density that impacts cooling effectiveness and may necessitate further derating or enhanced ventilation systems.

Vibration levels, mounting orientations, and duty cycle requirements also influence efficiency optimization strategies. Continuous duty applications benefit from different design approaches compared to intermittent or variable duty cycles. The selection of appropriate enclosure types, bearing systems, and cooling methods must align with the specific application requirements while maximizing energy efficiency. Proper environmental matching prevents efficiency degradation and extends motor operational life, reducing total cost of ownership.

Installation and Connection Best Practices

Power Quality and Electrical Connections

Power quality significantly impacts motor efficiency, with voltage unbalances, harmonic distortions, and frequency variations all contributing to increased losses and reduced performance. Voltage unbalances as small as 2-3% can increase motor losses by 15-25%, highlighting the importance of balanced three-phase supplies and properly sized conductors. Regular power quality monitoring helps identify issues that compromise efficiency, enabling corrective actions before significant energy waste occurs. High-quality electrical connections using appropriate conductor sizes and termination methods minimize voltage drops and resistance losses.

Harmonic distortions from non-linear loads can cause additional heating and efficiency losses in squirrel cage motors. Installing harmonic filters or line reactors may be necessary in facilities with significant electronic loads or variable frequency drives. The motor's electrical installation should include proper grounding systems that minimize circulating currents and electromagnetic interference. Cable routing and separation from other electrical systems prevent induced voltages and maintain signal integrity in control circuits.

Mechanical Installation and Alignment

Precise mechanical installation directly affects motor efficiency through its impact on bearing loads, vibration levels, and overall system performance. Shaft alignment tolerances must be maintained within manufacturer specifications to prevent premature bearing wear, increased friction losses, and efficiency degradation. Laser alignment systems provide the accuracy necessary for optimal installation, while regular alignment checks ensure continued peak performance. Improper alignment can increase energy consumption by 5-15% while significantly reducing bearing and coupling life.

Foundation design and mounting practices influence vibration transmission and motor stability, both of which affect efficiency and longevity. Rigid mounting systems prevent excessive movement that can cause misalignment and bearing stress, while vibration isolation may be necessary in sensitive applications. Belt drive systems require proper tensioning and pulley alignment to minimize efficiency losses, with over-tensioning being a common cause of premature bearing failure and increased energy consumption. Direct coupling arrangements eliminate belt losses but require more precise installation and maintenance practices.

Operational Optimization Techniques

Load Management and Process Integration

Effective load management strategies maximize motor efficiency by optimizing operating points and minimizing energy waste during partial load conditions. Variable frequency drives enable precise speed control that matches motor output to actual process requirements, eliminating throttling losses and improving overall system efficiency. The energy savings potential from VFD installations can range from 20-50% in variable torque applications such as fans and pumps, making them attractive investments for efficiency improvement programs.

Process integration opportunities include coordinating multiple motor operations to minimize peak demand charges and optimize overall facility energy consumption. Sequencing controls can start motors in predetermined orders that prevent excessive inrush currents and demand spikes. Energy management systems provide real-time monitoring and control capabilities that enable responsive optimization based on production requirements and energy costs. Smart scheduling algorithms can shift non-critical loads to off-peak periods, reducing energy costs while maintaining production efficiency.

Control System Implementation

Advanced control systems offer sophisticated optimization capabilities that continuously adjust motor operation for maximum efficiency. Soft starters reduce inrush currents and mechanical stress while providing controlled acceleration that can improve overall system efficiency. Energy-optimized control algorithms automatically adjust operating parameters based on load conditions, maintaining peak efficiency across varying operational requirements. These systems can provide real-time feedback about motor performance and efficiency trends, enabling proactive maintenance and optimization decisions.

Integration with facility management systems allows coordinated control of multiple motors and associated equipment for maximum energy efficiency. Demand response capabilities enable automatic load shedding during peak rate periods or grid stress conditions. Predictive control algorithms can anticipate load changes and preemptively adjust motor operation to maintain optimal efficiency levels. The implementation of these advanced control strategies requires careful planning and commissioning to ensure proper operation and maximum energy savings.

Maintenance Programs for Sustained Efficiency

Predictive Maintenance Strategies

Predictive maintenance programs utilize advanced monitoring technologies to detect efficiency-degrading conditions before they cause significant energy waste or equipment failure. Vibration analysis can identify bearing problems, misalignment, and unbalance conditions that increase friction losses and energy consumption. Thermal imaging reveals hot spots that indicate electrical connection problems, overloading, or cooling system deficiencies. Current signature analysis provides insights into rotor bar condition, air gap variations, and other internal problems that affect motor efficiency.

Motor current analysis systems continuously monitor electrical parameters to identify trends that indicate developing problems or efficiency degradation. These systems can detect issues such as bearing wear, rotor problems, and stator winding deterioration long before they become critical. Oil analysis programs for larger motors provide detailed information about bearing condition and lubrication effectiveness, enabling optimized maintenance schedules that maintain peak efficiency. The data collected through these monitoring programs supports informed decisions about repair versus replacement that consider both immediate costs and long-term efficiency implications.

Preventive Maintenance Protocols

Systematic preventive maintenance ensures that motors continue operating at peak efficiency throughout their service life. Regular cleaning of motor exteriors and cooling passages prevents heat buildup that reduces efficiency and accelerates component degradation. Lubrication programs must follow manufacturer specifications for grease types, quantities, and intervals to minimize bearing friction while avoiding over-lubrication that increases drag losses. Electrical connection inspections identify loose or corroded connections that contribute to voltage drops and resistance losses.

Air gap measurements during major overhauls ensure that rotor-to-stator clearances remain within specifications for optimal magnetic coupling and efficiency. Winding resistance measurements help identify developing insulation problems that could affect motor efficiency and reliability. Cooling system maintenance includes fan cleaning, air filter replacement, and ventilation path clearance to maintain adequate heat removal capacity. Documentation of maintenance activities and efficiency measurements creates a performance history that supports optimization decisions and helps identify trends that require attention.

Advanced Technologies and Upgrades

Variable Frequency Drive Integration

Variable frequency drives represent one of the most effective technologies for improving motor efficiency in applications with varying load requirements. Modern VFDs incorporate advanced algorithms that automatically optimize motor operation for maximum efficiency across different speed and torque conditions. Energy optimization features adjust voltage and frequency relationships to minimize losses while maintaining required performance levels. The payback periods for VFD installations typically range from 1-3 years in appropriate applications, making them attractive investments for energy efficiency programs.

Proper VFD selection and programming are crucial for realizing maximum efficiency benefits while avoiding potential problems such as motor heating or insulation stress. Carrier frequency selection affects both efficiency and noise levels, requiring careful consideration of application requirements. Input and output filtering may be necessary to minimize harmonic distortions and electromagnetic interference that could impact efficiency or other equipment operation. Regular VFD maintenance and parameter optimization ensure continued peak performance and maximum energy savings throughout the system's operational life.

Smart Motor Technologies

Intelligent motor systems incorporate sensors, communications, and control capabilities that enable continuous efficiency optimization and predictive maintenance. Built-in monitoring systems track key parameters such as temperature, vibration, and electrical characteristics, providing real-time feedback about motor condition and performance. Wireless communication capabilities allow remote monitoring and control that supports facility-wide energy management programs. These smart systems can automatically adjust operation for optimal efficiency and alert maintenance personnel about developing problems before they impact performance.

Internet of Things (IoT) integration enables advanced analytics and machine learning algorithms that continuously optimize motor operation based on historical performance data and current operating conditions. Cloud-based monitoring services provide expert analysis and recommendations for efficiency improvements and maintenance optimization. Digital twin technologies create virtual models of motor systems that enable advanced optimization strategies and predictive maintenance programs. The implementation of these advanced technologies requires careful planning and integration with existing facility management systems to maximize their effectiveness and return on investment.

FAQ

What is the typical efficiency improvement from upgrading to premium efficiency squirrel cage motors?

Premium efficiency squirrel cage motors typically provide 2-5% efficiency improvements compared to standard efficiency units, with larger motors showing greater absolute savings. The actual energy savings depend on motor size, operating hours, and load factors, but facilities often see 15-30% reductions in motor energy consumption when combining efficient motors with proper sizing and control systems. Payback periods typically range from 1-4 years depending on operating conditions and local energy costs.

How does motor loading affect energy efficiency in squirrel cage motors?

Motor efficiency typically peaks at 75-100% of rated load, with significant efficiency drops at partial loads below 50%. Lightly loaded motors operate at reduced power factors and increased per-unit losses, making proper sizing crucial for efficiency optimization. Variable frequency drives can help maintain efficiency at reduced loads by adjusting both voltage and frequency to match actual requirements, preventing the efficiency penalties associated with constant-speed operation at partial loads.

What maintenance practices most significantly impact squirrel cage motor efficiency?

Regular cleaning of cooling passages and motor exteriors prevents overheating that reduces efficiency, while proper lubrication minimizes bearing friction losses. Maintaining tight electrical connections prevents voltage drops and resistance heating, and ensuring proper alignment eliminates mechanical losses from shaft misalignment. Predictive maintenance programs that monitor vibration, temperature, and electrical parameters help identify efficiency-degrading conditions before they become critical problems.

Can older squirrel cage motors be retrofitted to improve energy efficiency?

While complete motor replacement often provides the best efficiency improvements, several retrofit options can enhance older motor performance. Variable frequency drive installation offers significant energy savings in variable load applications, while power factor correction capacitors can improve electrical efficiency. Rewinding with higher-grade materials and optimized designs can improve efficiency by 1-3%, though the cost-effectiveness depends on motor size and expected remaining service life compared to new premium efficiency alternatives.

Table of Contents

- Understanding Squirrel Cage Motor Fundamentals

- Motor Selection and Sizing Strategies

- Installation and Connection Best Practices

- Operational Optimization Techniques

- Maintenance Programs for Sustained Efficiency

- Advanced Technologies and Upgrades

-

FAQ

- What is the typical efficiency improvement from upgrading to premium efficiency squirrel cage motors?

- How does motor loading affect energy efficiency in squirrel cage motors?

- What maintenance practices most significantly impact squirrel cage motor efficiency?

- Can older squirrel cage motors be retrofitted to improve energy efficiency?