Principios Fundamentales del Ajuste de Velocidad del Motor: VFDs vs. Reductores

Comprensión de la Tecnología de Arranque Suave en VFDs

La tecnología de arranque suave en VFDs ha revolucionado la forma en que se inician los motores. Esta tecnología hace posible la aceleración gradual; el hecho de que la carga mecánica durante el arranque del motor se reduzca considerablemente también significa una vida útil más larga para los equipos mecánicos. La tecnología de arranque suave con reducción de voltaje disminuye la corriente de inserción, diseñada específicamente para reducir la demanda de corriente máxima del sistema eléctrico. Es especialmente importante en aplicaciones donde un movimiento repentino pueda causar daños, como en sistemas de bandas transportadoras o bombas, en donde se requiere un manejo suave de materiales o fluidos.

Tecnología de conversión de frecuencia para regulación de velocidad

La tecnología de conversión de frecuencia VFD, al cambiar la frecuencia de la alimentación eléctrica, es un mecanismo avanzado para controlar la velocidad del motor. Este proceso constituye un factor fundamental para controlar indirectamente la velocidad y eficiencia del motor, proporcionando un control preciso de la velocidad de rotación, lo cual es útil para la automatización de procesos en la fabricación. La argumentación a favor de implementar esta tecnología es sólida, ya que los datos muestran que los VFD pueden ahorrar el 50 % o más de la energía consumida por los sistemas en algunas aplicaciones. El ahorro masivo de energía no solo reduce los costos operativos, sino que también apoya el esfuerzo general de sostenibilidad de una empresa.

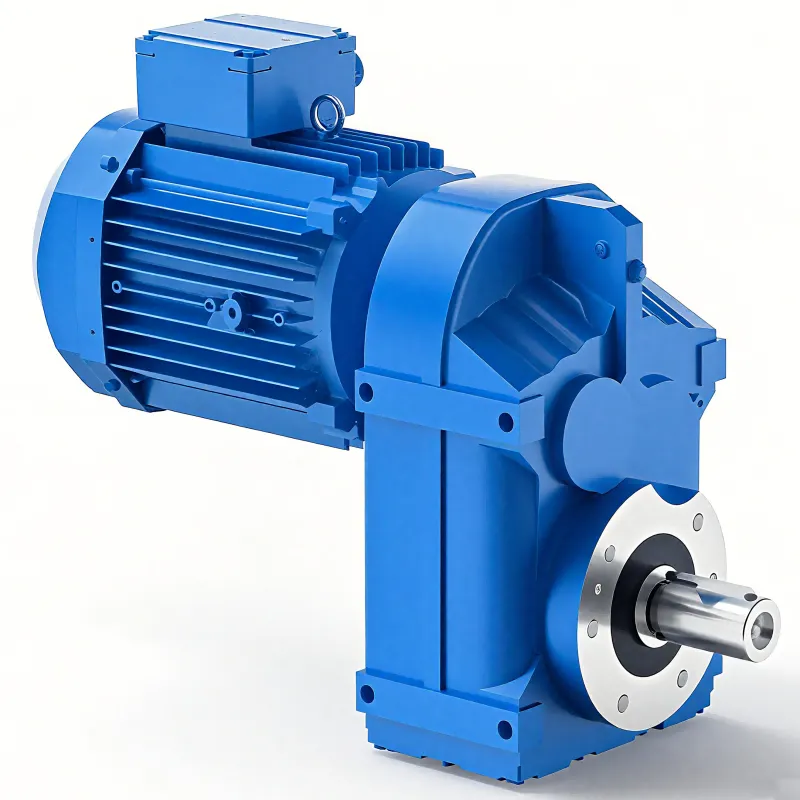

Control de Velocidad Mecánica en Reductores de Velocidad

Los reductores de engranajes tienen un medio mecánico sencillo para ajustar la velocidad de rotación de un motor, y esto normalmente garantiza un ajuste del output fácil y repetible, así como un aumento del par de salida según la relación de engranaje. Los reductores de engranajes tienen menos componentes que los variadores de frecuencia (VFDs) y no requieren el mantenimiento que estos últimos necesitan, por lo tanto son más adecuados para aplicaciones donde hay mucho trabajo (carga) con necesidad de durabilidad y fiabilidad. Sus configuraciones ofrecen una RPM Máxima de operación, proporcionando aplicación flexibilidad a través de las líneas industriales. Esta flexibilidad asegura que los reductores de engranajes puedan ser utilizados para satisfacer distintas características de rendimiento manteniendo la eficiencia en cualquier tipo de carga.

VFDs vs. Reductores: Dinámica de Par y Potencia

Aplicaciones de Par Constante vs. Par Variable

La clave para elegir el sistema de transmisión adecuado radica en conocer la diferencia entre par constante y par variable. Las bandas transportadoras, por ejemplo, se benefician muy bien de los variadores de frecuencia (VFD) utilizados en aplicaciones de par constante. Esto cumple con los requisitos de una rápida respuesta ante cambios de carga, lo que puede mantener la estabilidad del trabajo y ahorrar energía. Mientras tanto, aplicaciones de par variable como ventiladores, bombas y similares se desempeñan mejor con sistemas que proporcionen una gama de ajustes de rendimiento para operar con máxima eficiencia. El requisito específico de par de la aplicación probablemente determine la elección entre estos sistemas.

Relación RPM-Caballo de Fuerza en Sistemas Mecánicos

La conexión entre RPM (Revoluciones Por Minuto) y caballos de fuerza es muy básica cuando se trata del funcionamiento del motor. Esta relación interdependiente afecta la forma y el funcionamiento óptimo de los sistemas mecánicos. La mayoría de los fabricantes ofrecen gráficos que muestran comparaciones entre RPM y caballos de fuerza, lo cual también es útil para el usuario final al elegir las máquinas adecuadas. Cuando esta relación es bien conocida, se puede lograr el máximo aprovechamiento posible del motor, y ni los motores estarán en marcha en vacío, ni serán cargados con una dimensión incorrecta, lo cual generaría pérdidas de eficiencia.

Preservación del Flujo Magnético en Motores de Frecuencia

Los variadores de frecuencia tienen el potencial de controlar motores de manera muy eficiente utilizando el flujo magnético. Se identifican niveles ideales de flujo magnético para garantizar que no se pierda más energía de la necesaria, logrando así un desempeño óptimo del sistema. La investigación ha demostrado que la retención eficiente del flujo puede extender significativamente la vida útil de un motor. Esta ilustración del comportamiento magnético destaca la importancia de los variadores de frecuencia en la mejora del rendimiento, así como en el aumento de la vida útil y la confiabilidad de los sistemas de motores.

Capacidades de Control de Proceso en la Regulación de Velocidad

Integración de IIoT en Sistemas VFD Modernos

Los sistemas de variadores de frecuencia (VFD) hoy en día están equipados con tecnología IIoT inteligente, lo cual hace posible aumentar considerablemente sus funcionalidades. Gracias a la IIoT (Industrial Internet of Things), los VFD cuentan con capacidades de monitoreo remoto, permitiendo el análisis de datos en tiempo real. Este servicio posibilita realizar ajustes proactivos al sistema para incrementar la eficiencia operativa. Informes industriales muestran que cuando la IIoT se integra en los sistemas VFD, la producción puede mejorar hasta en un 30%, demostrando el gran potencial de la IIoT para la Automatización Industrial.

Desacoplamiento Velocidad-Torque en Reductores Mecánicos

Los reductores mecánicos destacan en el desacoplamiento velocidad-torque, ofreciendo un control independiente sobre la velocidad y la carga, lo que mejora la adaptabilidad. Este principio permite a los reductores mantener un rendimiento consistente bajo condiciones de carga variables. La capacidad de manipular el par de forma independiente de la velocidad es crucial para mantener la fiabilidad del proceso en diversas aplicaciones industriales.

Mantenimiento Predictivo a través del Control de Frecuencia

Los algoritmos de control de frecuencia son especialmente útiles en el mantenimiento predictivo, en donde se analizan datos de desempeño para prever necesidades de reparación. Esta estrategia reduce significativamente el tiempo de inactividad y los costos para las empresas. En un estudio sobre estrategias de mantenimiento predictivo, este tipo de práctica puede ahorrar un cuarto de los costos de mantenimiento, demostrando su atractivo económico.

Componentes principales y mecanismos de ahorro de energía

Arquitectura de potencia Rectificador-DC Bus-Inversor

La configuración rectificador-bus de CC-inversor es el bloque básico de los Variadores de Frecuencia (VFD) y permite convertir CA a CC y CC a CA, lo cual es fundamental para el funcionamiento del VFD. Esta arquitectura es importante para mejorar la eficiencia energética al reducir las pérdidas de energía debidas a la conversión de potencia. Estos sistemas también pueden eliminar muchas de las ineficiencias presentes en la mayoría de los entornos industriales cuando se diseñan adecuadamente. El análisis y optimización de esta estructura son necesarios para diseñar aplicaciones más dedicadas y eficaces. A través de la optimización orientada a la eficiencia, podemos reducir drásticamente los costos operativos y, en última instancia, mejorar la productividad en los procesos industriales.

Ajuste Dinámico de Carga para Eficiencia Energética

[La coincidencia dinámica de carga, el concepto clave en los sistemas modernos de VFD, es una técnica para variar la potencia dinámicamente con el fin de satisfacer requisitos específicos de carga. De esta manera, mejora considerablemente el ahorro de energía y reduce el desperdicio energético en condiciones variables de carga. Sitios que han adoptado esta técnica han experimentado ahorros energéticos de hasta un 20%, demostrando que esta estrategia es un éxito. Vale la pena mencionarlo, pero esta práctica sirve no solo para cumplir objetivos de sostenibilidad, al eliminar el desperdicio de energía, sino que asegura que el rendimiento de nuestros sistemas esté en su máxima eficiencia operativa el 100% del tiempo. La coincidencia dinámica de carga puede lograr ahorros significativos de costos y mejoras en eficiencia.

Pérdidas Hidráulicas en la Reducción de Velocidad Mecánica

El mecanismo de pérdida hidráulica de los MSR desempeña un papel importante en la mejora del rendimiento general de los sistemas. Estas pérdidas provocan, si no se mantienen bajo control, grandes pérdidas de energía. Los buenos diseños se centran en reducir estas pérdidas porque pueden tener un gran efecto sobre el rendimiento general de la turbina. Se acepta generalmente que es posible ahorrar más del 15 por ciento de energía optimizando los sistemas mecánicos para minimizar las pérdidas hidráulicas. Esto hace que el diseño y desarrollo de reductores mecánicos de velocidad sean más eficientes al controlar adecuadamente el sistema para no perder energía. Mitigando las pérdidas hidráulicas, tenemos la oportunidad de promover operaciones más eficientes y económicas en una amplia gama de aplicaciones industriales.

Seleccionar el Sistema de Control de Velocidad del Motor Adecuado

Análisis de Requisitos de Viscosidad y Par

Conocer la viscosidad de los fluidos con los que trabaja es fundamental para determinar la mejor opción de control de velocidad del motor. El requisito de par necesario para el funcionamiento lo controla la viscosidad, lo cual indirectamente define la selección entre un variador de frecuencia (VFD) y un reductor. Diversas aplicaciones presentan comportamientos diferentes en cuanto a viscosidad, por lo tanto se requiere una selección detallada para asegurar que el sistema elegido pueda proporcionar el par necesario de manera eficiente y sin consumir energía en exceso. La estimación realizada por expertos es clave en esta etapa para garantizar que las características del motor sean compatibles con las condiciones del sistema. Esto elimina cualquier inconveniente y maximiza el rendimiento de todas sus aplicaciones.

Ancho de banda de potencia vs. Ventaja mecánica

El equilibrio entre el ancho de banda de potencia y la ventaja mecánica es fundamental para un diseño eficiente del sistema de control del motor. El ancho de banda de potencia designa la cantidad de potencia que un sistema puede manejar eficientemente, mientras que la ventaja mecánica se puede decir que es la multiplicación de fuerza por el sistema. Dicho equilibrio óptimo afecta aspectos importantes del sistema, tales como los tiempos de respuesta del sistema, el rango de velocidad del sistema y la eficiencia general del sistema de control de velocidad del motor. En comparaciones a menudo se menciona que los variadores de frecuencia (VFD) generalmente tienen anchos de banda más amplios que los sistemas mecánicos convencionales, lo cual sugiere mayor flexibilidad para diferentes aplicaciones. Por lo tanto, comprender estas propiedades guiará el diseño de sistemas que equilibren efectividad y eficiencia.

Comparación de costo durante el ciclo de vida: VFD vs Caja de engranajes

Un análisis de costos del ciclo de vida completo entre variadores de frecuencia (VFD) y cajas de engranajes puede ser útil para comprender las consecuencias financieras de cada uno a largo plazo. El retorno de la inversión puede ser un poco más largo, pero en su mayor parte, esto se debe al costo adicional inicial de un VFD (porque un VFD no consume energía, simplemente la gestiona). Fuentes dentro de la industria suelen indicar que al elegir VFDs en lugar de cajas de engranajes estándar es posible ahorrar hasta un 40 % en costos del ciclo de vida. Esto ocurre porque los VFD son sistemas operativos flexibles y ahorradores de energía que generan ahorros significativos en gastos de mantenimiento y consumo energético. Considerar los costos del ciclo de vida puede ayudar a las empresas a tomar decisiones inteligentes que maximicen el rendimiento y el presupuesto.

Sección de Preguntas Frecuentes

¿Cuál es el papel de la tecnología de arranque suave en los VFDs?

La tecnología de arranque suave en CIFV permite una aceleración gradual, reduciendo el impacto mecánico y extendiendo la vida útil del equipo al minimizar la corriente de entrada. Esto es especialmente útil en operaciones delicadas como sistemas de transporte y bombas.

¿Cómo impacta la tecnología de conversión de frecuencia en el consumo de energía?

La tecnología de conversión de frecuencia ayuda a regular la velocidad del motor alterando la frecuencia de entrada, reduciendo el consumo de energía hasta en un 50% en ciertas aplicaciones, lo que disminuye los costos operativos y apoya los esfuerzos de sostenibilidad.

¿Por qué elegir reductores de velocidad sobre CIFV para ciertas aplicaciones?

Los reductores de velocidad ofrecen simplicidad, fiabilidad y menor mantenimiento que los CIFV, haciéndolos ideales para aplicaciones de carga pesada donde la durabilidad es crucial.

¿Cómo mejora la integración de la tecnología IIoT los VFD?

La integración de la tecnología IIoT en los VFD permite el monitoreo remoto, el análisis de datos en tiempo real y ajustes proactivos, mejorando la eficiencia operativa y aumentando la producción.

¿Cómo puede mejorar la eficiencia energética el emparejamiento dinámico de carga en sistemas VFD?

El emparejamiento dinámico de carga ajusta la potencia en tiempo real para cumplir con los requisitos de carga, mejorando significativamente la eficiencia energética y reduciendo el consumo de energía innecesario.

Tabla de Contenido

- Principios Fundamentales del Ajuste de Velocidad del Motor: VFDs vs. Reductores

- VFDs vs. Reductores: Dinámica de Par y Potencia

- Capacidades de Control de Proceso en la Regulación de Velocidad

- Componentes principales y mecanismos de ahorro de energía

- Seleccionar el Sistema de Control de Velocidad del Motor Adecuado

-

Sección de Preguntas Frecuentes

- ¿Cuál es el papel de la tecnología de arranque suave en los VFDs?

- ¿Cómo impacta la tecnología de conversión de frecuencia en el consumo de energía?

- ¿Por qué elegir reductores de velocidad sobre CIFV para ciertas aplicaciones?

- ¿Cómo mejora la integración de la tecnología IIoT los VFD?

- ¿Cómo puede mejorar la eficiencia energética el emparejamiento dinámico de carga en sistemas VFD?