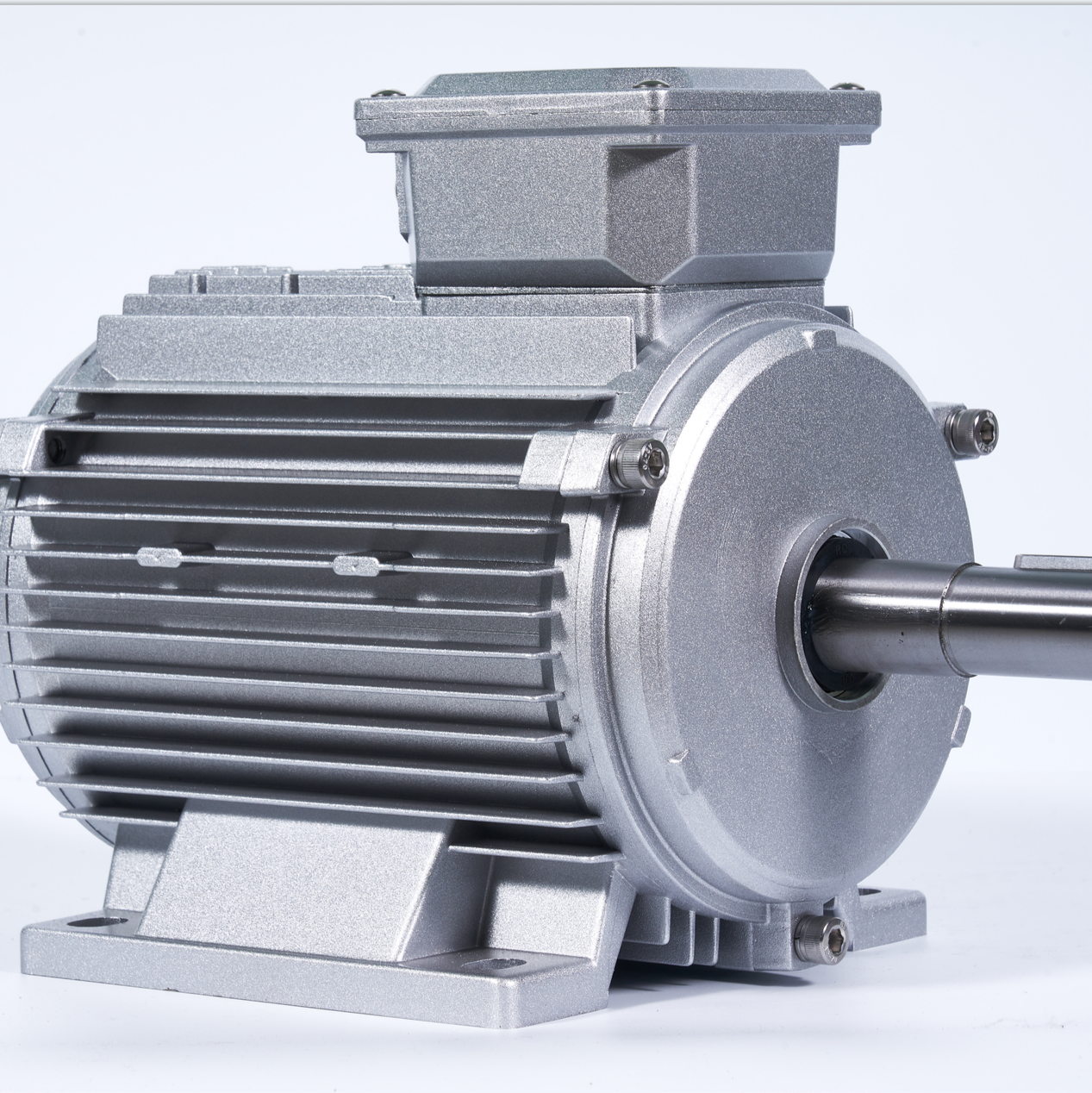

motor kafshër me tre faza

Motori me kafaz qimetësh është një element kyç në aplikimet e energjisë industriale, duke përfaqësuar një nga motorët më të përdorur elektrikë në prodhimin modern. Ky dizajn i motorit të fortë ka një strukturë të thjeshtë por efektive, të përbërë nga një stator me bobina të shpërndara dhe një rotor që përmban shufra conductuese të lidhura me unaza skaji. Statori krijon një fushë magnetike rrotulluese kur aktivizohet me energji të fazës së trefishtë, ndërsa struktura e formës së kafazit të rotori indukon rrjedhjen e rrymës, duke gjeneruar forcën elektromagnetike të nevojshme për rrotullim. Ajo që e dallon këtë motor është besueshmëria e jashtëzakonshme dhe kërkesat minimale për mirëmbajtje, falë mungesës së furçave, unazave lëvizëse apo pjesëve të komplikuara lëvizëse. Motori funksionon me furnizim standard të energjisë së fazës së trefishtë, zakonisht midis 208 deri në 480 volta, duke e bërë atë të përshtatshëm me shumicën e sistemeve industriale të energjisë. Dizajni i tij lejon konfigurime të ndryshme të shpejtësisë, nga aplikimet me një shpejtësi të vetme tek kombinimet me shpejtësi të shumëfishta të arritura përmes ndryshimit të poleve. Motori me kafaz qimetësh shkëlqen në aplikime që kërkojnë funksionim me shpejtësi konstante, si sistemet e transportuesve, pompët, ventillatorët dhe makinat e veglave. Konstruktesi i fortë i lejon të përballojë ambientet industriale të ashpra ndërkohë që mban performancë të vazhdueshme. Efikasiteti i motorit zakonisht lëviz nga 85% në 95%, varësisht nga madhësia dhe specifikimet e dizajnit, duke e bërë atë një zgjedhje të efikas në përdorimin e energjisë për aplikime të vazhdueshme.