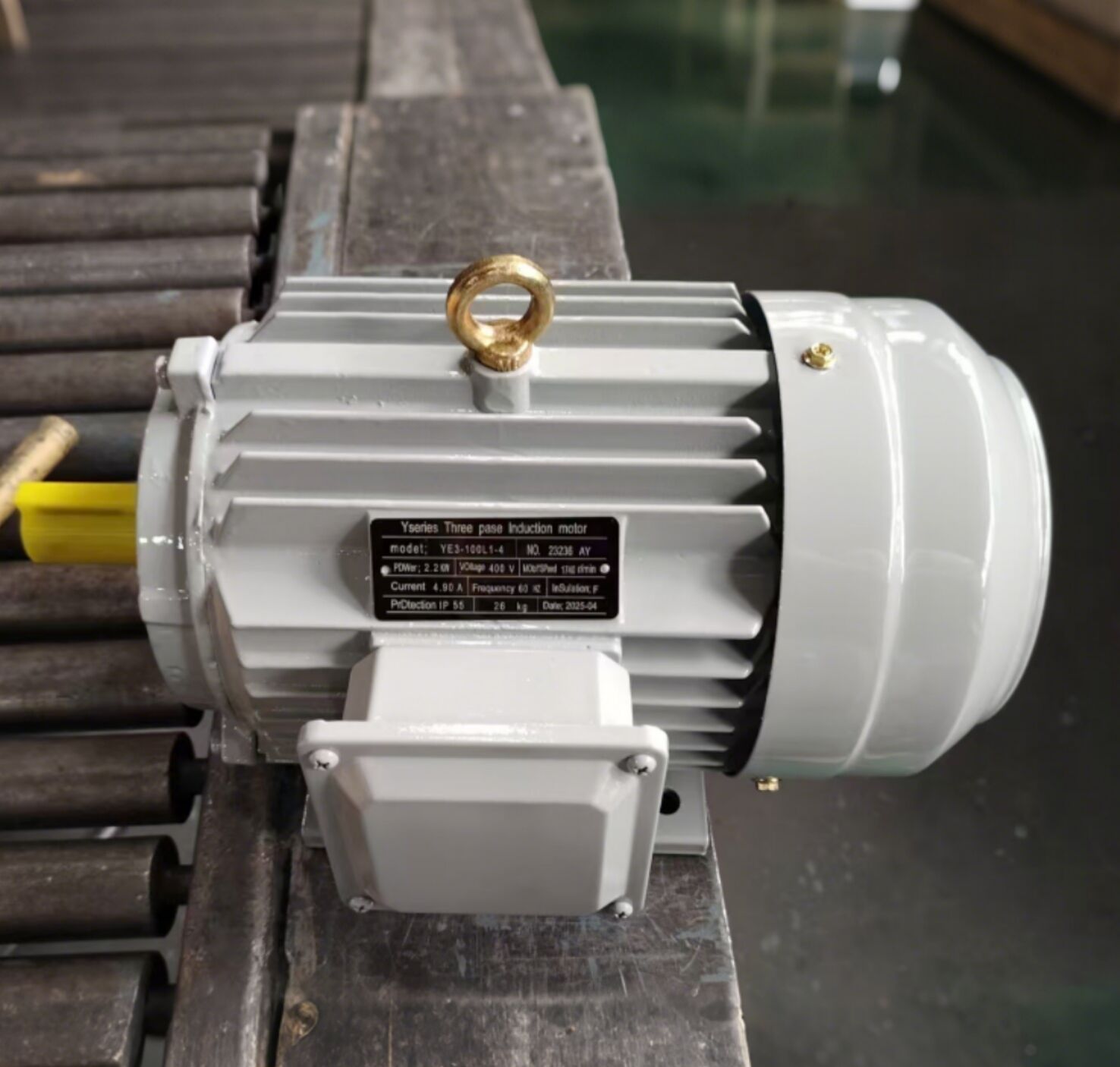

customized stator and rotor

The customized stator and rotor represent pinnacle engineering in electric motor technology, serving as crucial components that define motor performance and efficiency. These precision-engineered elements work in perfect synchronization, with the stator functioning as the stationary component housing the electromagnetic assembly, while the rotor serves as the rotating element that generates mechanical power. Through advanced manufacturing processes, these components can be tailored to specific applications, offering optimized electromagnetic properties, enhanced thermal management, and superior mechanical stability. The customization process encompasses various aspects, including material selection, lamination design, winding configurations, and cooling system integration. Modern manufacturing techniques enable the incorporation of advanced features such as specialized slot geometries, optimized air gaps, and innovative insulation systems. These customized components find applications across diverse industries, from high-precision manufacturing equipment to renewable energy systems, electric vehicles, and industrial automation. The ability to fine-tune these components ensures optimal performance in specific operating conditions, whether it's high-speed applications, heavy-duty industrial processes, or environments requiring precise motion control.