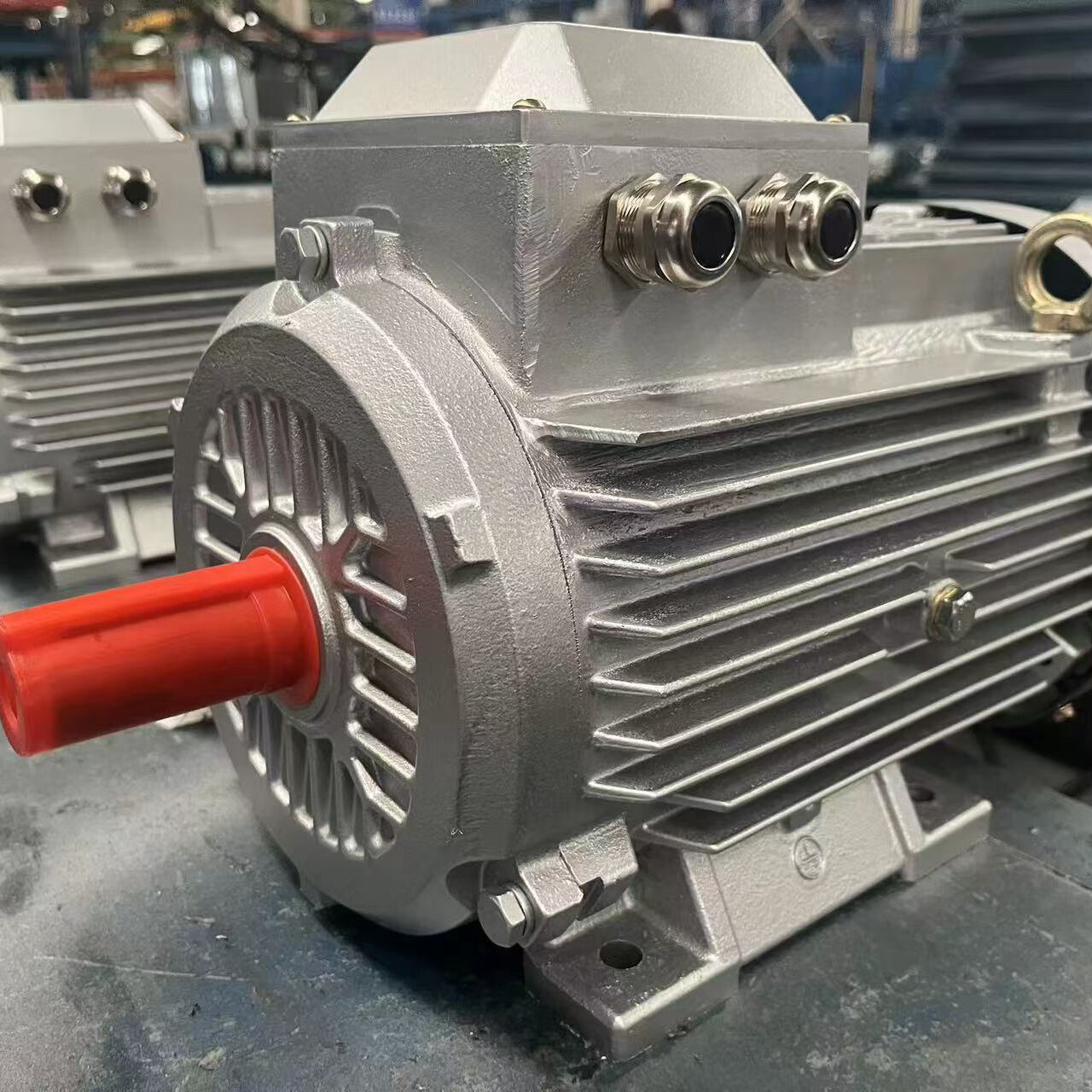

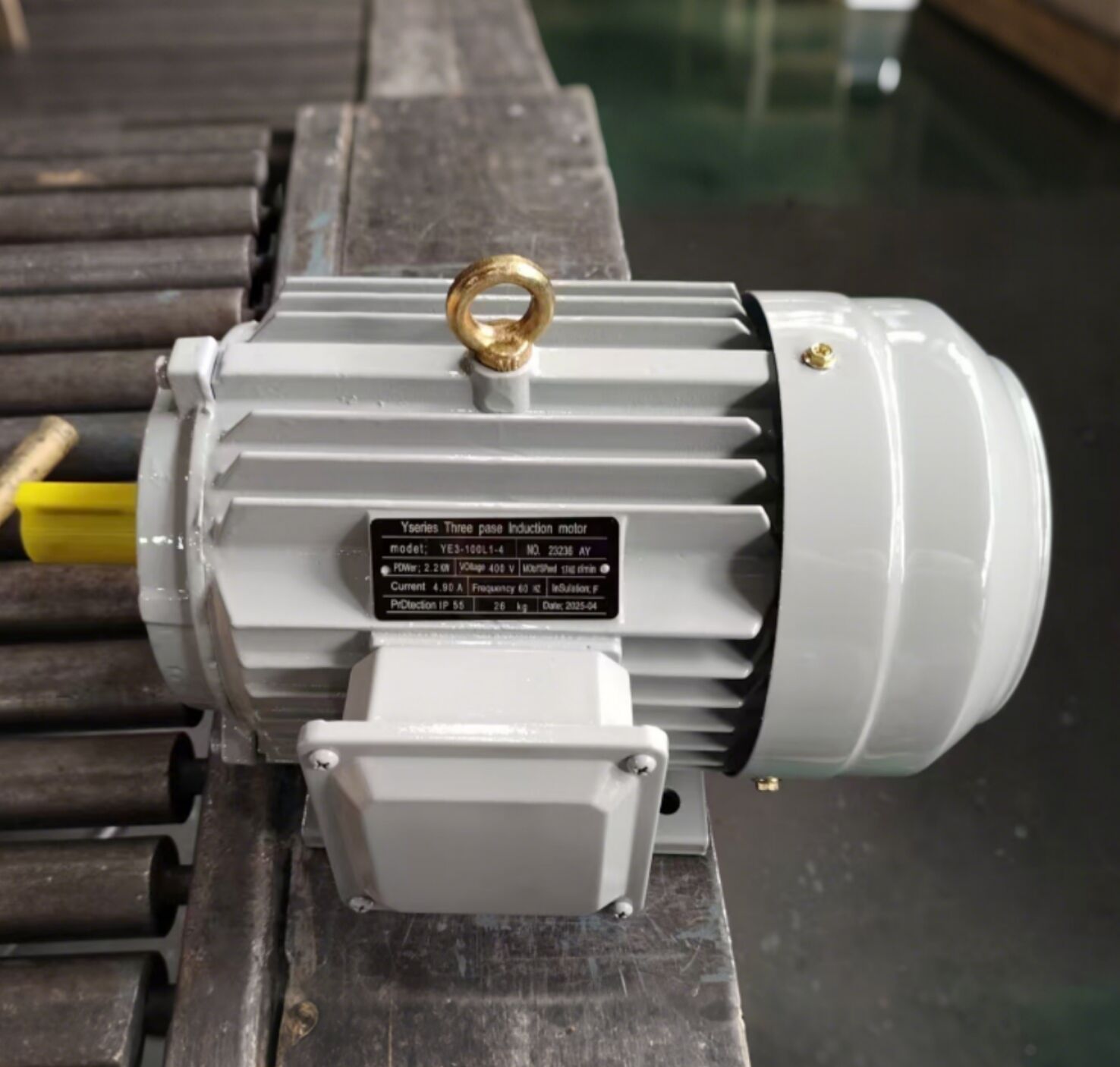

stator and rotor in induction motor

The stator and rotor are fundamental components of an induction motor, working in harmony to convert electrical energy into mechanical motion. The stator, the stationary part of the motor, consists of a steel frame housing a cylindrical core with uniformly spaced slots containing insulated windings. When connected to an AC power source, these windings create a rotating magnetic field. The rotor, the rotating component, features a cylindrical core with aluminum or copper bars embedded in a laminated steel core, forming what's known as a squirrel cage design. This ingenious arrangement allows for electromagnetic induction, where the stator's rotating magnetic field induces currents in the rotor bars, creating its own magnetic field. The interaction between these magnetic fields generates the torque necessary for rotation. The design incorporates precision engineering to maintain an optimal air gap between stator and rotor, ensuring efficient energy transfer while minimizing losses. This configuration makes induction motors highly reliable, efficient, and suitable for various industrial applications, from conveyor systems to pumps and compressors.