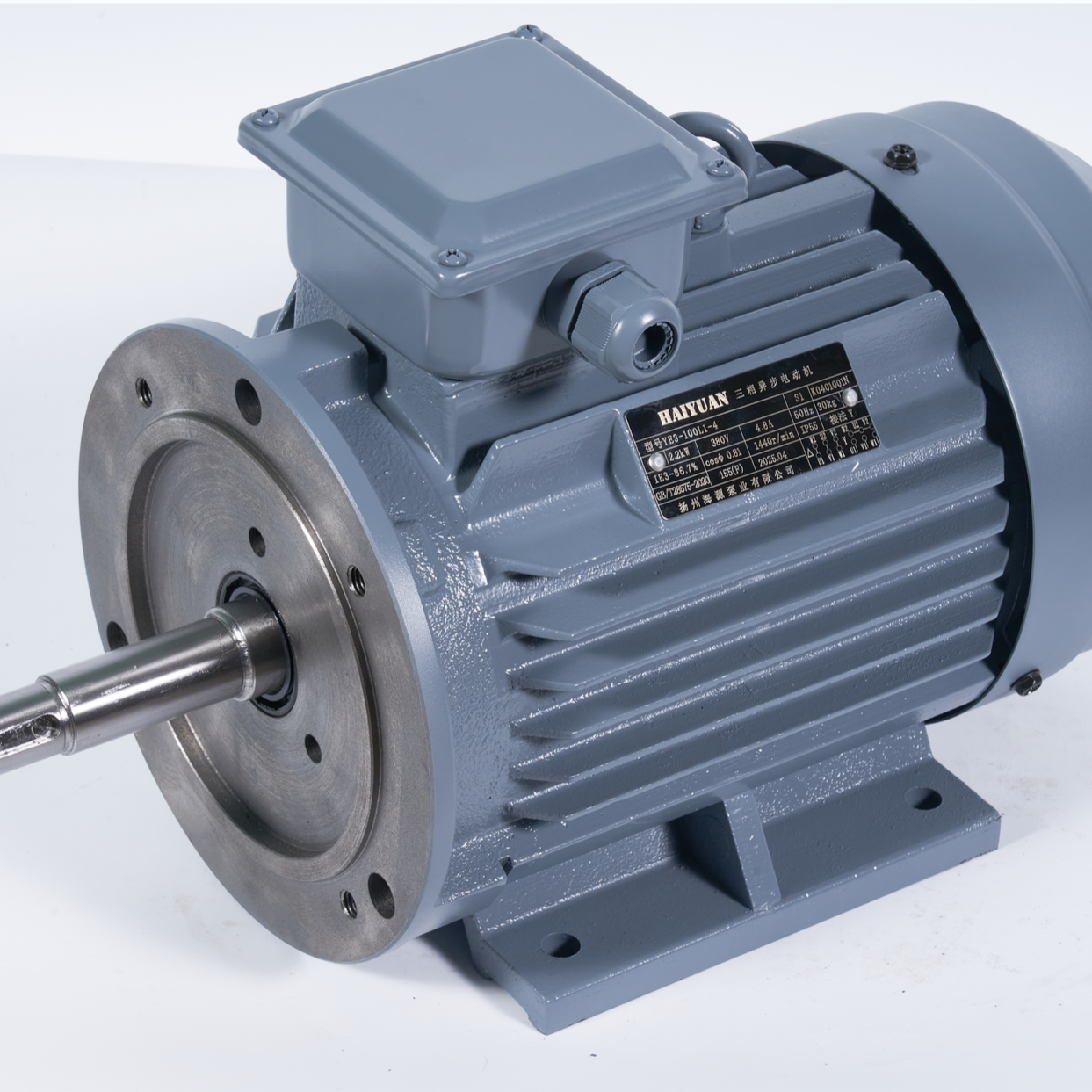

stator and rotor

The stator and rotor are fundamental components in electrical machines, working together to convert electrical energy into mechanical energy or vice versa. The stator, being the stationary part of the system, typically consists of a steel frame that houses wound coils of wire forming an electromagnet. These windings are carefully designed to create a rotating magnetic field when energized. The rotor, as the name suggests, is the rotating component that interacts with the stator's magnetic field. It can be constructed with either permanent magnets or electromagnetic windings, depending on the application. In motors, the stator's magnetic field induces motion in the rotor, while in generators, the rotor's movement through the stator's magnetic field generates electricity. This dynamic interaction is essential in various applications, from industrial motors to power generation facilities. Modern stator and rotor designs incorporate advanced materials and precise engineering to maximize efficiency and performance. The technology features sophisticated cooling systems, optimized magnetic circuits, and precise balancing to ensure smooth operation at various speeds. These components are crucial in electric vehicles, wind turbines, industrial machinery, and countless other applications where reliable electromechanical energy conversion is required.