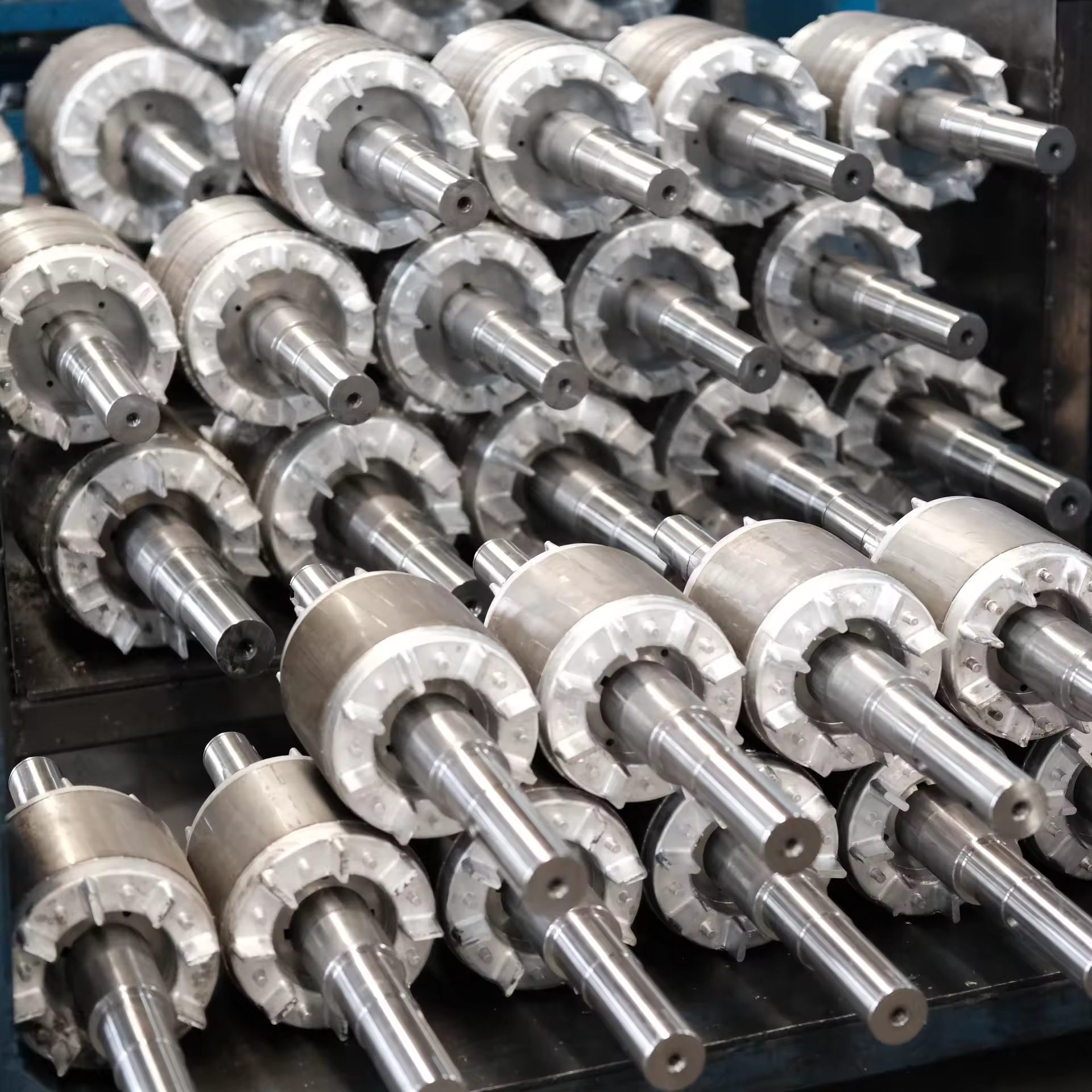

motor rotor stator

A motor rotor stator is a fundamental component in electric motors, comprising two essential parts: the stationary stator and the rotating rotor. The stator consists of a steel frame that houses electromagnetic windings or permanent magnets, creating a magnetic field when energized. The rotor, positioned inside the stator, contains its own set of windings or magnetic elements that interact with the stator's magnetic field to produce rotational motion. This electromagnetic interaction is the core principle behind electric motor operation. The design and construction of motor rotor stators have evolved significantly, incorporating advanced materials and precision engineering to enhance performance. Modern motor rotor stators feature optimized air gap dimensions between components, sophisticated lamination techniques to reduce energy losses, and improved cooling systems for thermal management. They are integral to various applications, from industrial machinery and household appliances to electric vehicles and renewable energy systems. The efficiency of a motor largely depends on the quality and design of its rotor stator assembly, which determines factors such as torque output, speed control, and energy consumption.