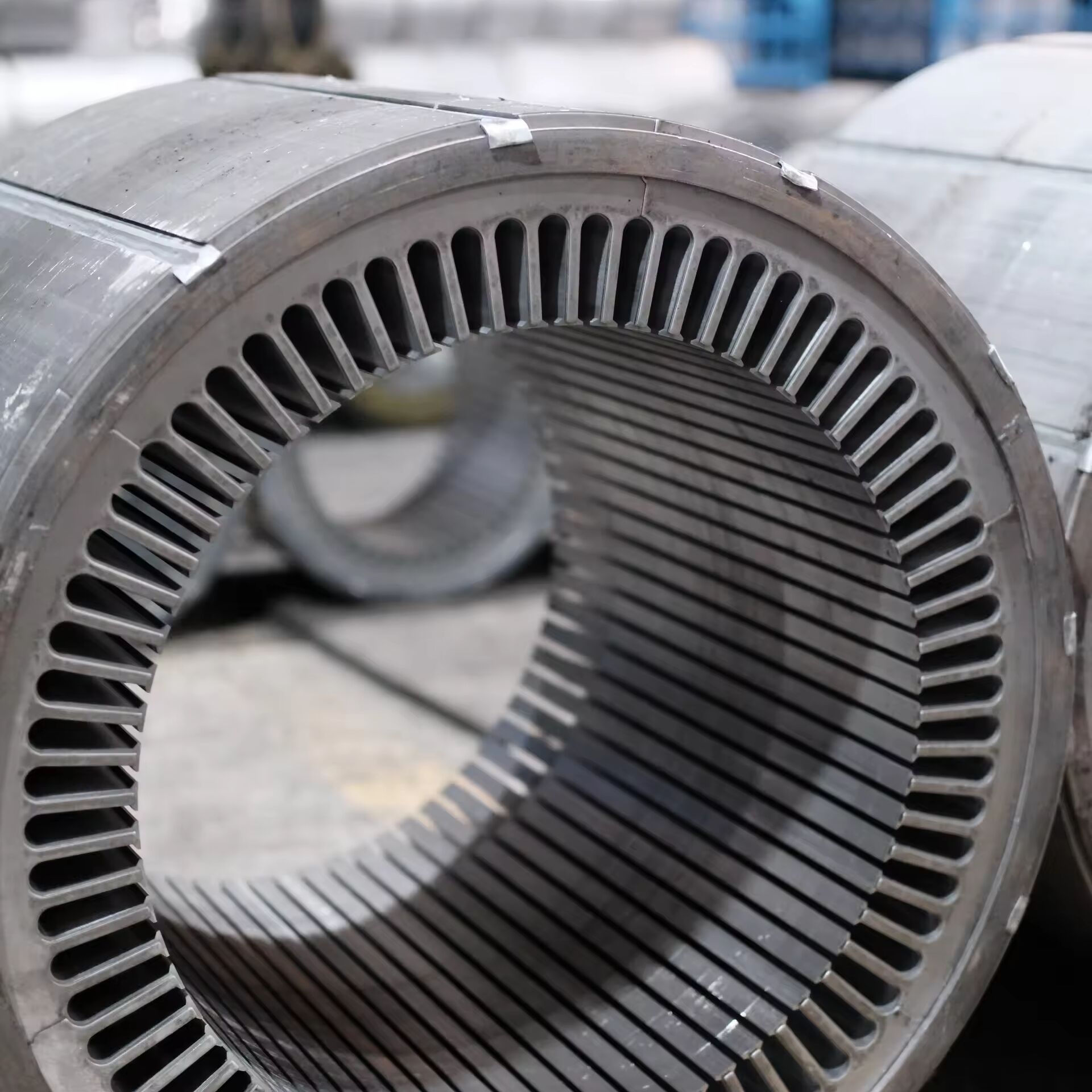

double squirrel cage induction motor

The double squirrel cage induction motor represents a significant advancement in electric motor technology, featuring two distinct rotor cages that work in harmony to deliver optimal performance across various operating conditions. The outer cage, constructed with higher resistance materials, provides excellent starting torque, while the inner cage, made of lower resistance materials, ensures efficient running performance at normal operating speeds. This unique design enables the motor to handle heavy starting loads while maintaining high efficiency during normal operation. The motor's construction includes specially designed conductor bars and end rings that facilitate the distribution of current between the two cages based on motor speed and load conditions. During startup, the majority of current flows through the outer cage due to higher reactance in the inner cage, resulting in increased starting torque. As the motor approaches its operating speed, current naturally shifts to the inner cage, providing superior running efficiency. This sophisticated design makes double squirrel cage induction motors particularly well-suited for applications requiring high starting torque and variable load conditions, such as conveyors, crushers, compressors, and heavy machinery in industrial settings. The motor's robust construction and reliable performance have made it a preferred choice in demanding industrial environments where both high starting torque and efficient continuous operation are essential.