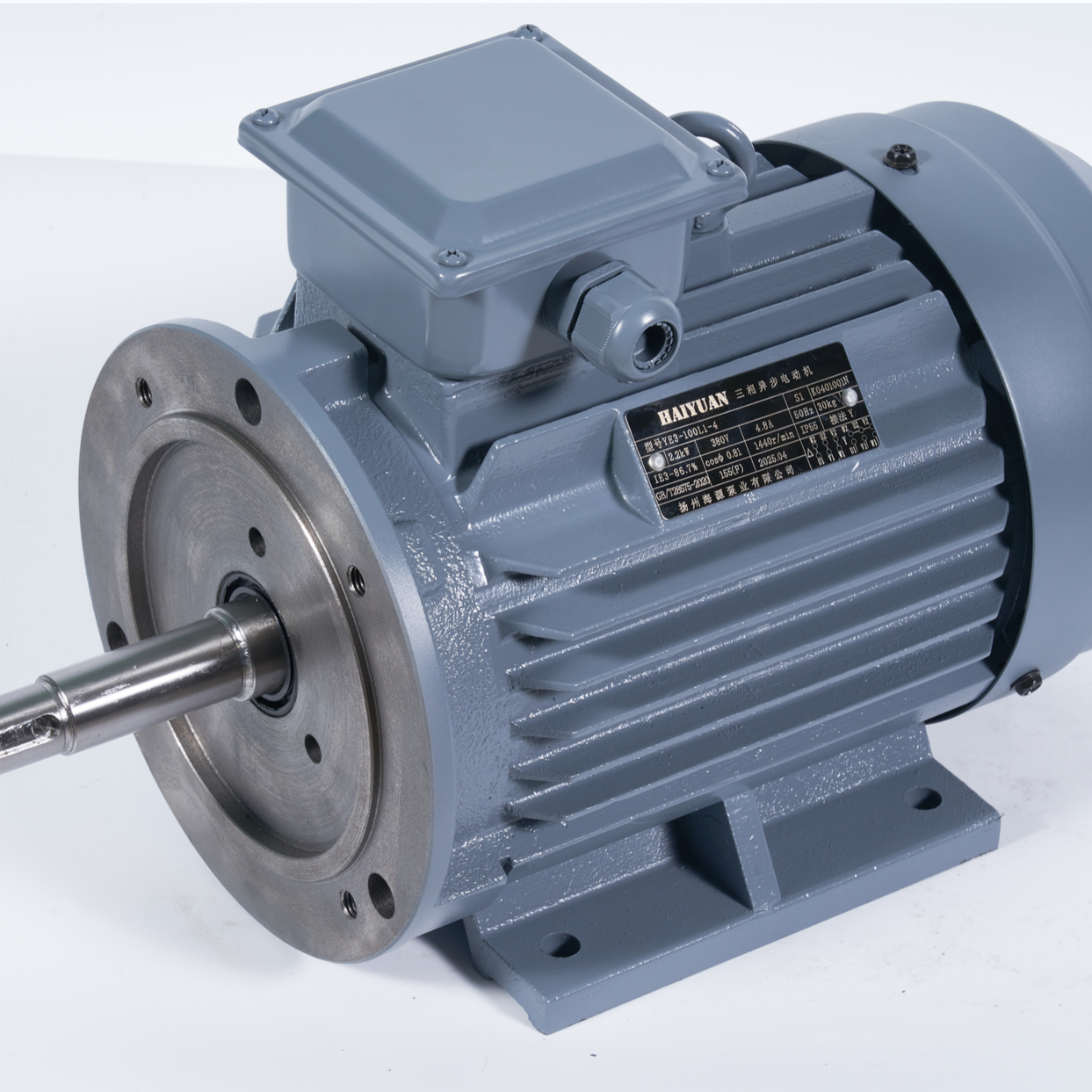

squirrel cage induction rotor

The squirrel cage induction rotor stands as a fundamental component in modern electric motors, characterized by its unique construction and reliable performance. This innovative design consists of a cylindrical laminated core with embedded aluminum or copper bars that run parallel to the shaft, connected by end rings to form a cage-like structure. The rotor operates on the principle of electromagnetic induction, where the rotating magnetic field from the stator induces current in the rotor bars, creating a magnetic field that interacts with the stator field to produce torque. The design's simplicity belies its technological sophistication, as the carefully calculated positioning of the rotor bars and the selection of materials directly influence motor efficiency and performance characteristics. In industrial applications, these rotors demonstrate exceptional durability due to their solid construction, requiring minimal maintenance while delivering consistent performance across various operating conditions. The squirrel cage design has become the industry standard for induction motors, powering everything from manufacturing equipment to HVAC systems, thanks to its cost-effective production methods and reliable operation. This rotor type excels in applications requiring constant speed operation, offering smooth acceleration and the ability to handle varying loads without significant performance degradation.