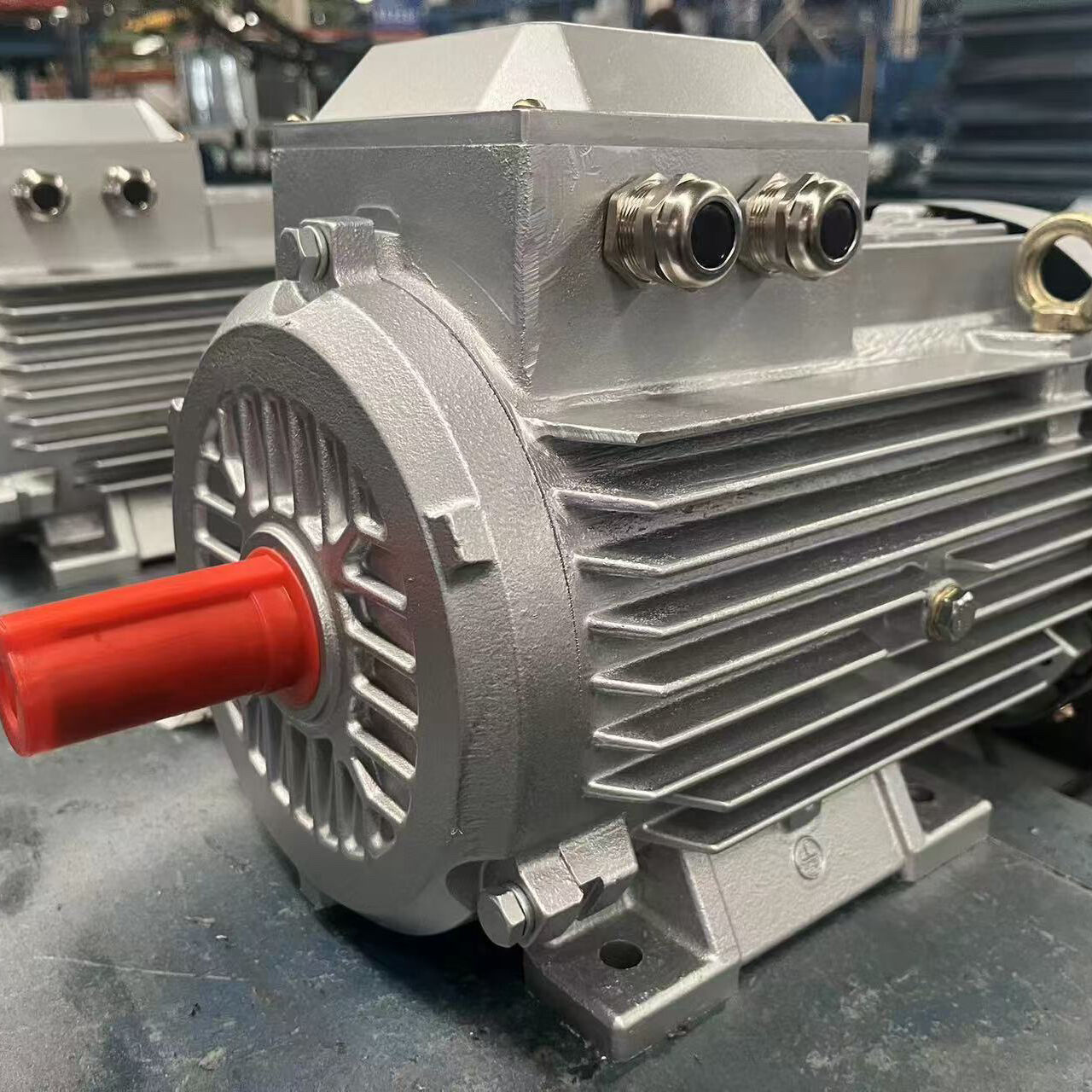

cage rotor motor

The cage rotor motor, also known as a squirrel cage motor, represents a cornerstone in industrial electric motor technology. This robust motor design features a cylindrical rotor core with embedded aluminum or copper bars connected by end rings, forming a structure resembling a cage. The rotor operates on electromagnetic induction principles, where the rotating magnetic field created by the stator windings induces current in the rotor bars, generating torque. This elegant yet simple design eliminates the need for brushes, slip rings, or complex winding patterns, making it exceptionally reliable and maintenance-friendly. The cage rotor construction allows for efficient heat dissipation and provides excellent starting torque characteristics. These motors typically operate at fixed speeds determined by the power supply frequency and the number of magnetic poles, though modern variable frequency drives can offer speed control capabilities. The cage rotor motor finds widespread application across various industries, from manufacturing and processing facilities to HVAC systems and material handling equipment. Its versatility makes it suitable for driving pumps, fans, conveyors, compressors, and numerous other industrial applications requiring reliable mechanical power.