Revolutionizing Industrial Power: The Evolution of Modern Electric Motors

The landscape of industrial power systems is undergoing a remarkable transformation, driven by groundbreaking advances in high voltage motor technology. These innovations are reshaping manufacturing processes, enhancing energy efficiency, and setting new standards for industrial performance. As industries worldwide embrace digital transformation, the evolution of high voltage motors stands at the forefront of this technological revolution, promising unprecedented levels of control, efficiency, and reliability.

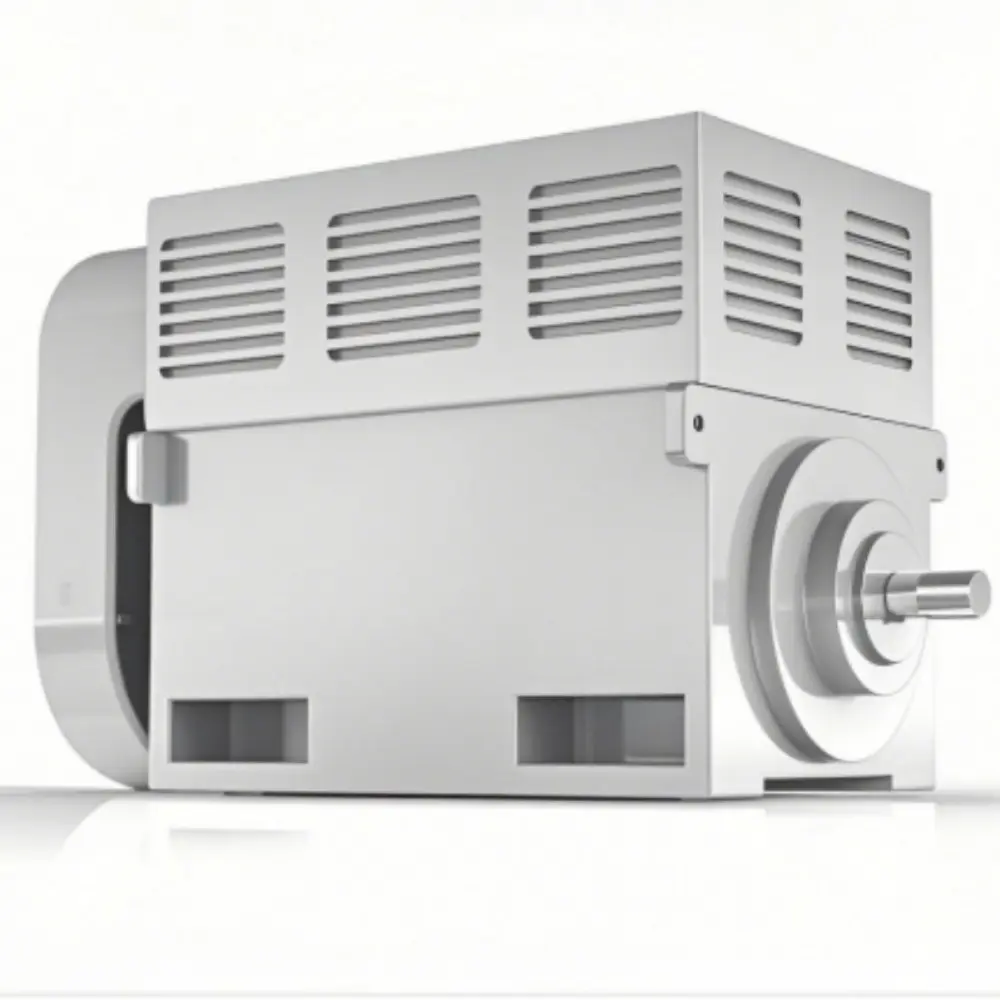

Today's high voltage motor technology represents a quantum leap forward from the conventional systems of the past. With the integration of smart sensors, advanced materials, and sophisticated control systems, modern electric motors are not just more powerful - they're smarter, more sustainable, and more adaptable to complex industrial demands.

Smart Integration and Digital Controls

Advanced Monitoring Systems

The integration of smart sensors and monitoring capabilities has revolutionized how high voltage motor technology operates in industrial settings. Modern motors now feature sophisticated sensor arrays that continuously monitor temperature, vibration, current, and voltage parameters in real-time. This constant surveillance enables predictive maintenance strategies, dramatically reducing unexpected downtime and extending motor life spans.

Digital twin technology has emerged as a game-changing innovation in motor monitoring. These virtual replicas of physical motors allow engineers to simulate operating conditions, predict potential failures, and optimize performance parameters without risking actual hardware. The implementation of such advanced monitoring systems has resulted in maintenance cost reductions of up to 30% while improving overall system reliability.

Intelligent Control Interfaces

Modern high voltage motor technology incorporates advanced control interfaces that enable precise speed regulation and torque control. These systems utilize sophisticated algorithms and machine learning capabilities to optimize motor performance based on real-time operating conditions. The integration of Industrial Internet of Things (IIoT) platforms allows for seamless communication between motors and other plant systems, creating a more coordinated and efficient operation.

Remote monitoring and control capabilities have become standard features in contemporary motor systems. Engineers can now adjust motor parameters, diagnose issues, and implement solutions from anywhere in the world, significantly reducing response times and improving operational efficiency.

Enhanced Efficiency and Sustainability Features

Advanced Materials and Construction

The development of new materials has significantly improved the efficiency of high voltage motor technology. Manufacturers are now utilizing advanced magnetic materials and innovative lamination techniques that minimize energy losses and improve motor performance. Silicon carbide (SiC) and gallium nitride (GaN) components are being incorporated into motor designs, offering superior thermal properties and higher switching frequencies.

Novel cooling systems, including advanced liquid cooling solutions and hybrid air-liquid systems, are enabling motors to operate at higher power densities while maintaining optimal temperature levels. These innovations have led to more compact designs without compromising performance or reliability.

Energy Recovery and Regeneration

Modern high voltage motor technology increasingly incorporates energy recovery systems that capture and reuse braking energy. This regenerative capability can significantly reduce overall energy consumption in applications with frequent start-stop cycles or variable load conditions. Some systems have demonstrated energy savings of up to 40% compared to conventional motors.

The integration of sophisticated power electronics allows for better power factor correction and harmonic distortion management, resulting in cleaner power consumption and reduced stress on electrical infrastructure. These improvements contribute to both environmental sustainability and operational cost reduction.

Variable Speed Applications and Load Management

Adaptive Speed Control

Advanced variable frequency drives (VFDs) have revolutionized how high voltage motor technology handles varying load conditions. Modern systems can automatically adjust motor speed and torque output to match exact process requirements, eliminating energy waste from oversized motors running at constant speeds. These adaptive control systems can respond to load changes in milliseconds, ensuring optimal performance under all operating conditions.

The implementation of sensorless control algorithms has further enhanced motor performance while reducing system complexity and cost. These sophisticated control methods can accurately estimate motor speed and position without physical sensors, improving reliability while maintaining precise control.

Dynamic Load Optimization

Recent innovations in high voltage motor technology include advanced load management systems that can handle rapid changes in demand while maintaining stability. These systems utilize predictive algorithms to anticipate load variations and adjust motor parameters accordingly, preventing voltage dips and ensuring smooth operation even under challenging conditions.

The integration of artificial intelligence has enabled more sophisticated load balancing capabilities, allowing multiple motors to work in harmony while optimizing overall system efficiency. This coordinated approach has proven particularly valuable in complex industrial applications where multiple drives must work together seamlessly.

Frequently Asked Questions

How do smart sensors improve motor reliability?

Smart sensors in high voltage motor technology continuously monitor critical parameters such as temperature, vibration, and electrical characteristics. This real-time monitoring enables predictive maintenance, early fault detection, and optimal performance adjustment, significantly reducing unexpected failures and extending motor lifespan.

What are the primary benefits of modern variable frequency drives?

Modern VFDs offer precise speed control, improved energy efficiency, reduced mechanical stress, and better power factor correction. They enable soft starting and stopping, which extends equipment life and reduces maintenance requirements while providing significant energy savings through optimized motor operation.

How does regenerative braking technology work in industrial motors?

Regenerative braking in high voltage motor technology converts mechanical energy during deceleration into electrical energy, which can be fed back into the power system or stored for later use. This technology significantly improves system efficiency, particularly in applications with frequent stopping and starting cycles.