Understanding the Key Performance Elements of Low Speed Electric Motors

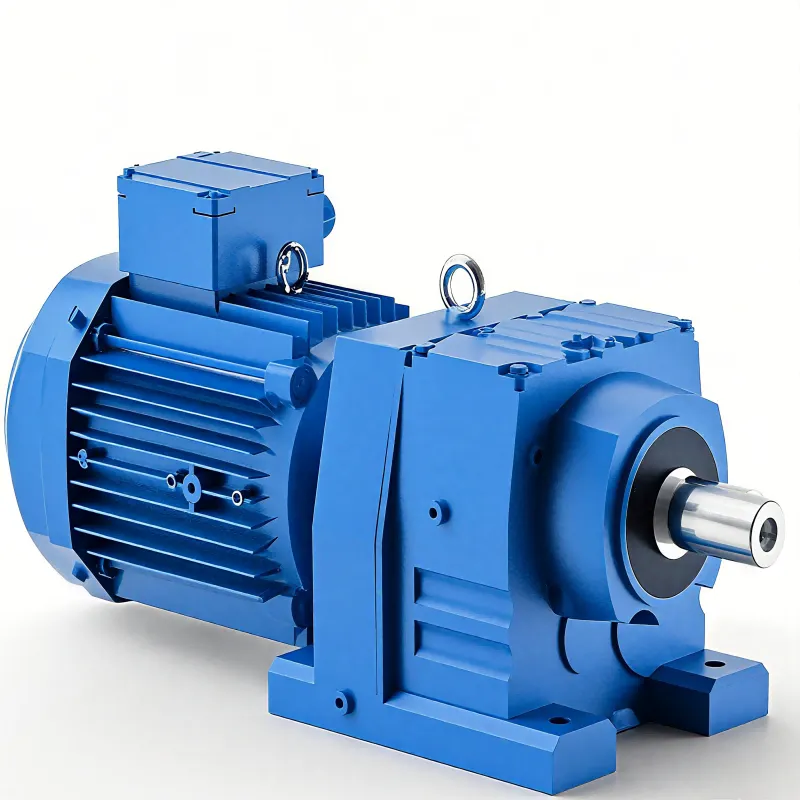

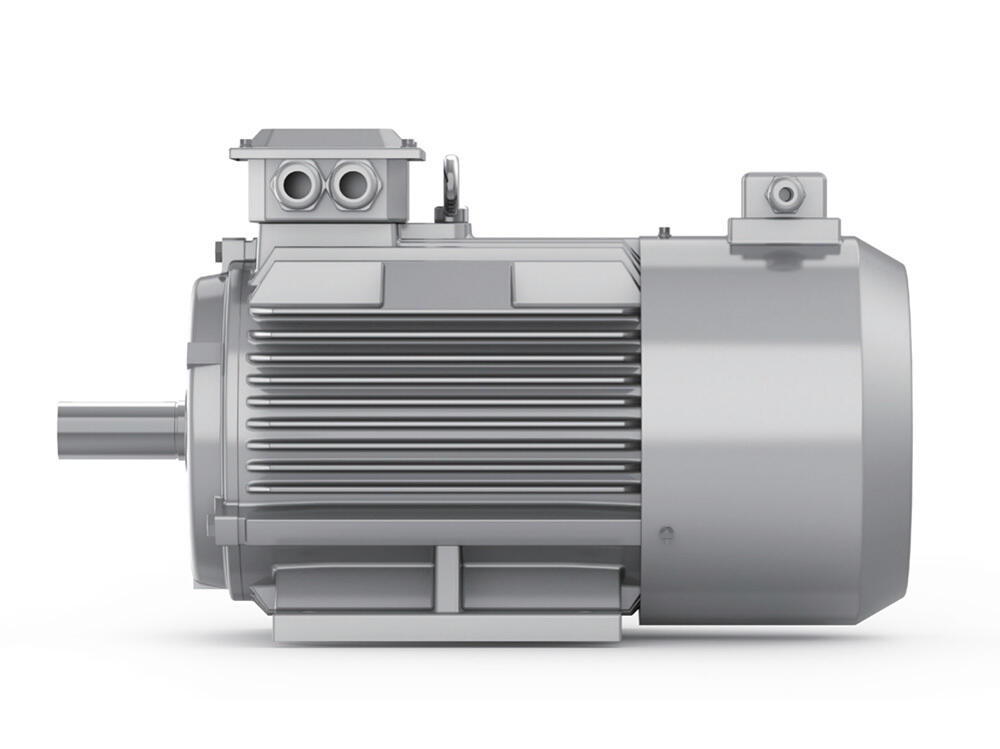

In industrial and commercial applications, low speed motors serve as critical components in numerous systems where precise control and reliable operation at reduced speeds are essential. The performance of these specialized motors depends on multiple interconnected factors that engineers and maintenance professionals must carefully consider. From environmental conditions to load characteristics, each element plays a vital role in determining how effectively a low speed motor will function in real-world applications.

Modern manufacturing and processing facilities rely heavily on low speed motor systems for applications requiring controlled movement and torque delivery. Whether it's in conveyor systems, mixing equipment, or specialized machinery, understanding these performance factors becomes crucial for optimal operation and longevity of the motor system.

Environmental and Operating Conditions

Temperature and Humidity Impact

The ambient temperature and humidity levels significantly affect how a low speed motor performs. High temperatures can lead to increased resistance in the motor windings, resulting in reduced efficiency and potential overheating. Conversely, extremely cold environments may affect the viscosity of lubricants and cause mechanical stress on motor components.

Humidity presents its own set of challenges, particularly in environments where moisture levels fluctuate dramatically. Excessive moisture can lead to condensation within the motor housing, potentially causing electrical shorts or accelerated corrosion of vital components. Proper ventilation and appropriate IP-rated enclosures become essential in managing these environmental factors.

Dust and Contaminants

Industrial environments often contain airborne particles that can severely impact a low speed motor's performance. Dust accumulation on cooling fins reduces heat dissipation efficiency, while fine particles can infiltrate bearings and other moving parts, increasing friction and wear. Regular maintenance schedules must account for these environmental challenges to ensure sustained performance.

The presence of chemical contaminants can also accelerate the degradation of motor components, particularly in processing facilities where corrosive substances are present. Specialized protective coatings and sealed designs help mitigate these risks, but regular monitoring remains crucial.

Mechanical Load Characteristics

Starting Load Requirements

The initial torque required to overcome static friction and inertia significantly influences a low speed motor's performance. Heavy starting loads can stress the motor's components and affect its lifespan. Proper sizing and selection of motor specifications must account for these starting conditions to ensure reliable operation.

Variable load applications present additional challenges, as the motor must maintain consistent performance despite fluctuating demand. Advanced control systems and proper motor selection become crucial in managing these dynamic load conditions effectively.

Continuous Operating Load

The sustained load during normal operation directly affects motor efficiency and heat generation. Operating a low speed motor consistently near its maximum rated capacity can lead to increased wear and reduced service life. Understanding the duty cycle and implementing appropriate cooling solutions helps maintain optimal performance under continuous load conditions.

Load variations during operation can create additional stress on motor components. Proper monitoring systems and predictive maintenance protocols help identify potential issues before they affect performance significantly.

Electrical Power Quality

Voltage Stability

Fluctuations in supply voltage can dramatically impact the performance of a low speed motor. Undervoltage conditions may result in increased current draw and potential overheating, while overvoltage situations can stress insulation and other electrical components. Voltage regulation and power conditioning equipment often become necessary in environments with unstable power supplies.

Power factor considerations also play a crucial role, particularly in industrial settings where multiple motors operate simultaneously. Proper power factor correction helps maintain efficient operation and prevents unnecessary strain on the electrical system.

Harmonic Distortion

Modern variable frequency drives, while providing excellent speed control, can introduce harmonic distortion into the power supply. These harmonics may cause additional heating in the motor windings and reduce overall efficiency. Implementing appropriate filtering solutions and selecting compatible drive systems helps minimize these effects.

Regular monitoring of power quality parameters ensures early detection of potential issues that could affect motor performance. Advanced diagnostic tools and power quality analyzers play a vital role in maintaining optimal operating conditions.

Maintenance and Service Factors

Lubrication Requirements

Proper lubrication is essential for the smooth operation of low speed motors, particularly in bearing systems. The type, quantity, and frequency of lubrication directly impact performance and service life. Regular inspection and maintenance schedules must account for operating conditions and environmental factors that affect lubricant degradation.

Different applications may require specialized lubricants based on speed, load, and environmental conditions. Developing and following a comprehensive lubrication program helps prevent premature wear and maintains optimal performance.

Alignment and Balance

Precise alignment between the motor and driven equipment is crucial for optimal performance. Misalignment can lead to increased vibration, accelerated wear, and reduced efficiency. Regular monitoring and adjustment of alignment parameters help maintain proper operation and prevent premature component failure.

Balance issues in rotating components can create additional stress on bearings and other motor parts. Implementing vibration monitoring programs and conducting regular balance checks helps identify and correct potential problems before they affect performance significantly.

Frequently Asked Questions

How does temperature affect low speed motor performance?

Temperature impacts low speed motor performance by affecting winding resistance, lubricant viscosity, and overall efficiency. High temperatures can lead to reduced power output and accelerated component wear, while low temperatures may affect starting torque and mechanical operation. Maintaining appropriate operating temperatures through proper ventilation and cooling systems is essential for optimal performance.

What role does power quality play in motor operation?

Power quality significantly influences low speed motor performance through voltage stability, harmonic content, and power factor. Poor power quality can result in increased heating, reduced efficiency, and potential damage to motor components. Installing appropriate power conditioning equipment and monitoring systems helps maintain reliable operation.

How often should low speed motors be maintained?

Maintenance frequency depends on operating conditions, environment, and application requirements. Generally, low speed motors should undergo regular inspection and maintenance at intervals determined by factors such as duty cycle, environmental exposure, and criticality of the application. A comprehensive maintenance program typically includes monthly visual inspections, quarterly vibration analysis, and annual detailed assessments.