रिड्यूसर मोटर्स को समझें: मुख्य कार्य और महत्व

मैकेनिकल सिस्टम में मूलभूत भूमिका

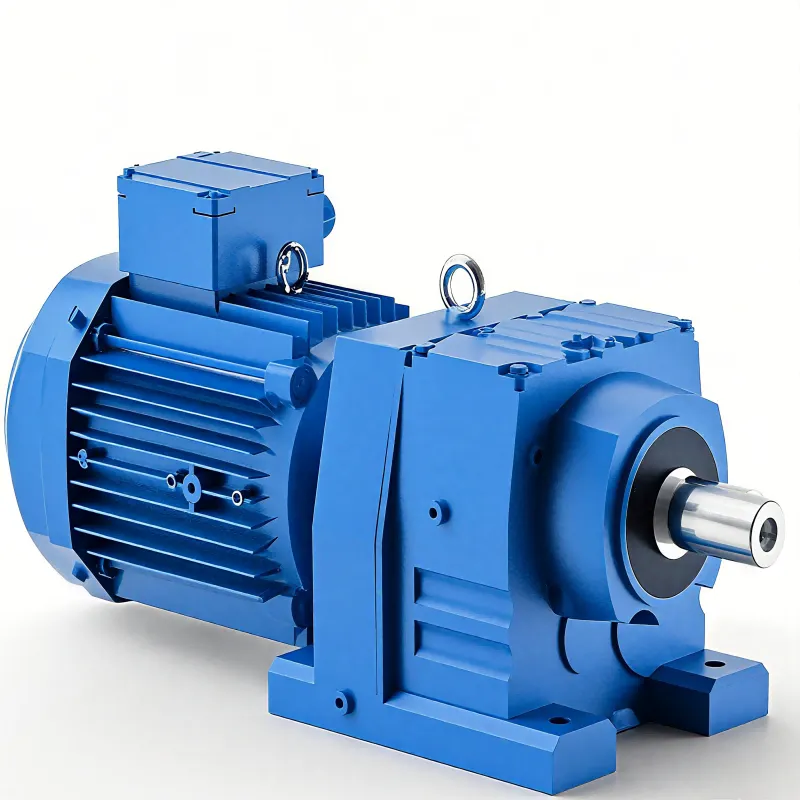

रिड्यूसर मोटर्स सभी प्रकार के यांत्रिक सिस्टमों में एक बहुत महत्वपूर्ण भूमिका निभाती हैं। ये मोटर्स इस बात को नियंत्रित करके कि चीजें कितनी तेजी से चलती हैं और किस प्रकार का बल उत्पन्न करती हैं, दक्षता और प्रदर्शन में सुधार करने में मदद करती हैं। ये मोटर्स उन औद्योगिक स्थापनाओं के लिए लगभग अनिवार्य हैं, जहां सब कुछ सही तरीके से काम करना बहुत महत्वपूर्ण होता है। अधिकांश कारखानों में बिना इनके सब कुछ सुचारु रूप से नहीं चल पाता। कुछ उद्योग सांख्यिकीय आंकड़ों के अनुसार, उचित ढंग से स्थापित की गई रिड्यूसर मोटर्स मशीनों को लगभग 30% अधिक कुशलता से काम कर सकती हैं, जिसी कारण इंजीनियर इन पर बहुत ध्यान देते हैं। जब हम अपने आसपास के सामान्य उपकरणों पर नज़र डालते हैं, तो ये मोटर्स मशीन को शक्ति प्रदान करने वाले भागों और वास्तविक कार्य करने वाले भागों के बीच की कड़ी के रूप में काम करती हैं। यह संबंध यह सुनिश्चित करता है कि सब कुछ लगातार दिन-प्रतिदिन सुचारु रूप से काम करे और समय के साथ अनावश्यक क्षति को भी रोकने में मदद करे।

रिड्यूसर मोटर कैसे टॉक़ और चाल को बदलते हैं

रिड्यूसर मोटर्स गियर अनुपात बदलकर आउटपुट गति और टॉर्क को समायोजित करते हैं, जिससे मशीनें विभिन्न कार्यों के लिए बेहतर ढंग से काम कर सकें। इंजीनियरों को यह समझने की आवश्यकता होती है कि टॉर्क और गति में परिवर्तन कैसे एक साथ काम करते हैं जब वे सभी प्रकार के भार और गति के साथ काम करने वाले सिस्टम की डिज़ाइन करते हैं। जब गियर सही ढंग से सेट होते हैं, तो मोटर्स अधिक कुशलता से चलते हैं और अधिक समय तक चलते हैं, विशेष रूप से जब बदलते कार्यभार का सामना करना पड़ता है। यहां ध्यान देने वाली मुख्य संख्या रिडक्शन अनुपात है, क्योंकि यह मोटर के शक्ति आउटपुट और समग्र प्रदर्शन को सीधे प्रभावित करता है। उचित सेटअप के साथ, ये मोटर्स चाहे बुनियादी उपकरण हों या जटिल कारखानों के सिस्टम जिन्हें टॉर्क की सही मात्रा और नियंत्रित गति की आवश्यकता होती है, सबकुछ सुचारु रूप से चलाते रहते हैं।

अधिकतम प्रदर्शन के लिए महत्वपूर्ण चयन पैरामीटर

ऊर्जा आवश्यकताएँ और मोटर संगतता

मैकेनिकल एप्लीकेशन के लिए रिड्यूसर मोटर्स का चयन करते समय, सबसे पहले बिजली की आवश्यकताओं की जांच करना आवश्यक होता है। यह प्रक्रिया मूल रूप से यह सुनिश्चित करना है कि मोटर की बिजली विनिर्देश उपलब्ध नियंत्रण प्रणालियों के साथ ठीक से काम करे ताकि सब कुछ विश्वसनीय रूप से चले। यह सही करना महत्वपूर्ण है क्योंकि यदि बिजली की रेटिंग मेल नहीं खाती है, तो यह भविष्य में समस्याएं पैदा करती है। असंगत मोटर्स अक्सर अक्षमतापूर्वक काम करती हैं और जल्दी खराब हो जाती हैं, जिसके बारे में अधिकांश मोटर निर्माता किसी भी पूछने वाले को बताएंगे। यह देखें कि क्या होता है जब कोई ऐसा व्यक्ति मोटर स्थापित करता है जिसके पीछे पर्याप्त शक्ति नहीं है - यह अक्सर ओवरहीट हो जाती है या बिना जरूरत के बिजली की खपत करती है। किसी विशेष मोटर पर सहमति बनाने से पहले, स्मार्ट तकनीशियन हमेशा तीन मुख्य बातों की जांच करते हैं: बिजली कहां से आ रही है, कितने वोल्टेज स्तर की आवश्यकता है, और पूरे सिस्टम को वास्तव में कितनी ऊर्जा की खपत होती है। इस तरह के प्रारंभिक मूल्यांकन से औद्योगिक विभिन्न स्थानों पर ऑपरेशन सुचारु रूप से चलते हैं और उपकरणों का जीवनकाल बढ़ता है।

गति अनुपात और कुशलता पर विचार

रिड्यूसर मोटर्स के मामले में, गति अनुपात यह निर्धारित करने में प्रमुख भूमिका निभाता है कि वे विभिन्न प्रकार के भारों के साथ कैसे प्रदर्शन करते हैं, विशेष रूप से। इस अनुपात को सही ढंग से प्राप्त करना टॉर्क आउटपुट में बड़ा अंतर लाता है, जिससे उपकरणों को संचालन के दौरान ऊर्जा बचाने में मदद मिलती है। उदाहरण के लिए, विनिर्माण संयंत्रों पर विचार करें, जहां 10% बेहतर दक्षता जैसे छोटे सुधार से समय के साथ वास्तविक बचत हो सकती है, विशेष रूप से उन मशीनों पर जो पारियों के दौरान लगातार चलती रहती हैं। हालांकि, सही गति अनुपात का चयन कुछ ऐसा नहीं है जिसे जल्दबाजी में किया जाना चाहिए। इसके लिए आवश्यक है कि व्यवस्था को प्रतिदिन किस प्रकार के कार्यभार का सामना करना पड़ता है, इसका अवलोकन किया जाए। इंजीनियरों को यह निर्धारित करने की आवश्यकता होती है कि न केवल मशीन को वर्तमान में क्या आवश्यकता है, बल्कि भविष्य की स्थितियों की भी भविष्यवाणी करनी चाहिए ताकि मोटर बिजली बर्बाद न करे या अप्रत्याशित तनाव के तहत संघर्ष करे।

टॉक घनत्व और संचालन सीमाएँ

टॉर्क घनत्व मूल रूप से यह बताता है कि मोटर अपने भौतिक आयामों और वजन की तुलना में कितना मरोड़ बल उत्पन्न कर सकती है। यह माप यह निर्धारित करने में एक महत्वपूर्ण भूमिका निभाती है कि क्या किसी विशेष कार्य के लिए मोटर अच्छी तरह से काम करेगी या नहीं। सिस्टम डिज़ाइन करते समय, इंजीनियरों को यह जानना आवश्यक होता है कि मोटर वास्तव में क्या संभाल सकती है, इससे पहले कि चीजें गलत होने लगें। मोटरों पर भार अधिक होने से अपेक्षाकृत जल्दी खराबी होती है और इसके परिणामस्वरूप भविष्य में मरम्मत पर अधिक धन खर्च करना पड़ता है। अधिकांश उद्योगों में मोटरों के चयन और उनके प्रतिस्थापन की योजना बनाने के लिए विभिन्न प्रकार के उपकरणों के लिए स्वीकार्य टॉर्क स्तरों के बारे में निर्धारित दिशानिर्देश होते हैं। वास्तविक दुनिया के आंकड़ों को देखने से पता चलता है कि इन सिफारिश की गई सीमाओं के भीतर रहने से मोटरों के लंबे समय तक चलने के साथ-साथ बिजली के बिलों में कमी आती है। दिन-प्रतिदिन मशीनरी चलाने वाले किसी भी व्यक्ति के लिए यह सही तरीके से निर्धारित करना वैसे तो खर्च पर नियंत्रण रखने के लिए बहुत महत्वपूर्ण है, साथ ही कार्यप्रवाह के लिए भी।

अक्ष अनुक्रमण: सह-अक्षीय, समानांतर, या लম्बवत

रिड्यूसर मोटर में शॉफ्ट कैसे बैठती है, यह विभिन्न यांत्रिक व्यवस्थाओं में फिट होने के मामले में बहुत मायने रखता है। उचित अभिविन्यास सुनिश्चित करने से आंतरिक घटकों पर दबाव कम होता है और स्थापना काफी आसान हो जाती है। सीमित जगह के लिए कोएक्सियल व्यवस्था अच्छी काम करती है क्योंकि वे कम जगह लेती हैं, जबकि समानांतर विन्यास इंजीनियरों को कार्यात्मक रूप से चीजों को एक साथ फिट करने के अधिक विकल्प प्रदान करते हैं। किसी भी यांत्रिक प्रणाली को तैयार करते समय, शॉफ्ट की स्थिति के बारे में सोचना समग्र प्रदर्शन में सुधार करने में मदद करता है। दक्षता और स्थायित्व के लिए उचित संरेखण भी तार्किक है। गलत तरीके से संरेखित मोटर्स का अधिक समय तक उपयोग करने पर अतिरिक्त तनाव के कारण जल्दी पहनने का कारण होता है, जिससे उनके बदलने की आवश्यकता पड़ती है।

रिडিযूसर मोटर के प्रकार और उनके अनुप्रयोग

ग्रहीय गियर मोटर: उच्च-टोक प्रसिद्धि

जब एप्लिकेशन को उच्च टॉर्क के साथ-साथ कॉम्पैक्ट डिज़ाइन की आवश्यकता होती है, तो प्लैनेटरी गियर मोटर्स वास्तव में उत्कृष्ट प्रदर्शन करती हैं। ये मोटर्स सीमित जगह में शक्तिशाली क्षमता रखती हैं और सटीक नियंत्रण बनाए रखती हैं, जिससे वे ऐसी स्थितियों के लिए आदर्श बन जाती हैं, जहां हर इंच मायने रखता है। फैक्ट्री के फर्श पर उद्योग रोबोट्स से लेकर पैकेजिंग लाइनों में कन्वेयर बेल्ट तक, निर्माता इन मोटरों पर भरोसा करते हैं क्योंकि ये संकीर्ण स्थानों में बेहतर ढंग से काम करती हैं। कुछ अध्ययनों में दिखाया गया है कि ये सिस्टम व्यवहारिक रूप से 90% से अधिक दक्षता दर्ज करते हैं, जिसका अर्थ है कि कंपनियां समय के साथ अपने ऊर्जा बिलों पर पैसा बचा सकती हैं। इन्हें खास क्या बनाता है? गियर्स की विशेष व्यवस्था लोड को कई बिंदुओं पर समान रूप से वितरित करती है, इसलिए घटक जल्दी खराब नहीं होते। यह डिज़ाइन विशेषता उन कठोर परिचालन स्थितियों में विशेष मूल्य रखती है, जहां विश्वसनीयता सबसे अधिक मायने रखती है।

वर्म गियर मोटर्स: सुरक्षा और उच्च-अनुपात समाधान

वॉर्म गियर मोटर्स उच्च अनुपात वाले समाधान प्रदान करने में अलग दिखते हैं क्योंकि इनमें यह उपयोगी स्व-ताला लगाने की सुविधा होती है जो विभिन्न अनुप्रयोगों में चीजों को सुरक्षित रखती है। इन मोटर्स को इतना उपयोगी बनाने वाली बात यह है कि ये वापसीय गति को रोक सकती हैं, जिसका अर्थ है कि ये लिफ्टों और कन्वेयर बेल्ट जैसी जगहों पर बहुत अच्छा काम करती हैं जहां सब कुछ सुरक्षित रखना सबसे महत्वपूर्ण होता है। इंजीनियरों ने बार-बार देखा है कि ये गियर अनुपात में भारी कमी को कैसे संभाल सकते हैं, जो बड़ी औद्योगिक मशीनरी के लिए बहुत महत्वपूर्ण है जिसे गंभीर शक्ति संचरण की आवश्यकता होती है। जब कंपनियां अन्य विकल्पों की तुलना में वॉर्म गियर मोटर्स का चुनाव करती हैं, तो आमतौर पर यह दुर्घटनाओं के विरुद्ध अतिरिक्त सुरक्षा परत प्राप्त करने के लिए होता है, विशेष रूप से तब जब भी भार होता है जो यदि उचित ढंग से नियंत्रित न किया जाए, तो समस्याएं पैदा कर सकता है।

गियर ट्रेन मोटर: लागत-कुशल ऊर्जा परिवहन

शक्ति संचरण विकल्पों के अवलोकन के समय, गियर ट्रेन मोटर्स अपनी सरलता और बजट-अनुकूलता के कारण एक विश्वसनीय विकल्प के रूप में उभरते हैं। इन मोटरों की मूलभूत बनावट के कारण ये न्यूनतम रखरखाव के साथ विश्वसनीय ढंग से काम करती हैं, जिससे विभिन्न औद्योगिक स्थितियों में इनका उपयोग उपयुक्त रहता है। संख्याओं पर गौर करने से पता चलता है कि कंपनियां गियर ट्रेन सिस्टम चुनकर शुरुआत में ही धन बचा सकती हैं, साथ ही ये काफी लंबे समय तक चलते हैं और बदलने की आवश्यकता नहीं होती। कई मध्यम श्रेणी की मशीनें वास्तव में इन मोटरों पर निर्भर करती हैं क्योंकि ये अधिक जटिल विकल्पों के अतिरिक्त विशेषताओं के बिना ही काम पूरा कर लेती हैं। कारखानों के प्रबंधकों को यह बात पसंद आती है कि इन प्रणालियों को समय के साथ बनाए रखना कितना आसान है, जिससे संचालन निर्बाध रूप से चलता रहता है और भविष्य में अप्रत्याशित खराबी या महंगी मरम्मत की समस्याएं नहीं आतीं।

बेवल गियर मोटर: कोणीय पावर स्थानांतरण

जब हमें किसी कोण पर शक्ति स्थानांतरित करने की आवश्यकता होती है, तब कोणीय गियर मोटर्स बहुत अच्छा काम करते हैं, जिससे शक्ति की दिशा बदलने की आवश्यकता होने पर लगभग अनिवार्य बन जाते हैं। किसी भी कारखाने के फर्श के चारों ओर देखो और ये गियर हर जगह दिखाई देते हैं, विशेष रूप से कन्वेयर बेल्ट सिस्टम में और कारों के अंदर जहां स्थान सीमित है और कोणों का बहुत महत्व है। इंजीनियरों के अनुसार, जब गति को विभिन्न दिशाओं में स्थानांतरित किया जाता है, तो ये गियर वास्तव में काफी हद तक दक्षता में वृद्धि करते हैं। जब कोणीय गियर मोटर का चयन करते हैं, तो इसे वास्तविक कार्य की आवश्यकताओं के अनुरूप मिलाना बहुत महत्वपूर्ण है। इसे सही करने से समग्र बेहतर सटीकता और ऐसी प्रणालियां होती हैं, जो बिना किसी समस्या के चलती रहती हैं, जिससे अधिकांश ऑपरेशन के लिए लंबे समय में समय और धन की बचत होती है।

बोझ क्षमता और ड्यूटी साइकिल की मांगों को मिलाना

ऑपरेशनल टोक़ आवश्यकताओं की गणना

वास्तविक अनुप्रयोगों में मोटर्स द्वारा निर्धारित कार्य करने की क्षमता सुनिश्चित करने के लिए संचालन के लिए सही टॉर्क संख्या प्राप्त करना बहुत महत्वपूर्ण है। टॉर्क आवश्यकताओं का पता लगाते समय, इंजीनियरों को कई कारकों पर विचार करने की आवश्यकता होती है, जिसमें भार का वजन, त्वरण की आवश्यकता की दर, साथ ही सिस्टम घटकों में घर्षण से होने वाले ऊर्जा नुकसान शामिल हैं। अधिकांश क्षेत्र मैनुअल मानक सूत्रों में ये मान डालकर वास्तविक कार्य स्थितियों के तहत मोटर के प्रदर्शन का एक वास्तविक अनुमान लगाने का सुझाव देते हैं। टॉर्क विनिर्देशों पर अच्छा अभिलेखन रखने से अप्रत्याशित समस्याओं के उबरने में होने वाली परेशानियों को रोकने में मदद मिलती है, इसके अलावा यह मोटर्स के लंबे समय तक चलने में भी सहायता करता है, जिससे उनकी मरम्मत या प्रतिस्थापन की आवश्यकता कम पड़ती है। भविष्य में समस्या निवारन की आवश्यकता पड़ने पर समय और धन बचाने के लिए वर्तमान में एक साधारण लॉगबुक प्रविष्टि काफी हद तक उपयोगी होती है, बजाय इसके कि असफलता के बाद प्रतिक्रिया करने के।

निरंतर बनाम अनियमित कर्तव्य परिस्थितियाँ

जब निरंतर बनाम अनियमित कार्य के लिए मोटर का चयन करने का समय आता है, तो सही काम को सही ढंग से करने में इसका बहुत अंतर होता है। निरंतर चलने वाली मोटर्स को पूरे दिन स्थिर भार का सामना करना पड़ता है, इसलिए गर्मी के संचयन की समस्याओं पर नज़र रखना बेहद जरूरी होता है। अनियमित कार्य वाली मोटर्स के साथ स्थितियां अलग होती हैं, क्योंकि ये अपने संचालन चक्र के दौरान बदलते हुए भारों का सामना करती हैं, जिसका अर्थ है कि विनिर्देशों की सावधानीपूर्वक जांच करना आवश्यक हो जाता है। उद्योग के आंकड़े यह दर्शाते हैं कि कार्य चक्र के गलत प्रकार का चयन करने से बाद के चरणों में कई समस्याएं उत्पन्न होती हैं, जैसे प्रदर्शन में कमी और मोटर के जीवनकाल में कमी। जब इंजीनियर मोटरों का उनके निर्धारित कार्य चक्र के साथ उचित मिलान करते हैं, तो वे मशीनों के भीतर चीजों को सुचारु रूप से चलाने में सक्षम होते हैं, बदले में प्रतिस्थापन पर धन बचाते हैं और सामान्य रूप से उपकरणों के जीवनकाल को बढ़ा देते हैं ताकि मरम्मत या प्रतिस्थापन की आवश्यकता न पड़े।

अतिभार का मोटर की लंबी उम्र पर प्रभाव

औद्योगिक स्थितियों में रिड्यूसर मोटर्स पर बहुत अधिक भार डालना वास्तव में उन समस्याओं में से एक है जिसे हम बहुत अक्सर देखते हैं। जब ये मोटर्स बहुत अधिक टॉर्क के तहत चलते हैं, तो वे भीतर से बाहर की ओर टूटना शुरू कर देते हैं, गर्म हो जाते हैं, और अंततः महंगी मरम्मत या बदले जाने वाले भागों की आवश्यकता होती है। कुछ क्षेत्र डेटा दर्शाता है कि डिज़ाइन विनिर्देशों से अधिक धकेले गए मोटर्स अपनी आयु का केवल आधा ही भाग तय कर पाते हैं। इसलिए उपकरण की आयु के लिए निर्माता के दिशानिर्देशों का पालन करना बहुत महत्वपूर्ण है। यहाँ टॉर्क सेंसर जैसी चीजों की स्थापना करना उचित है। कई विनिर्माण संयंत्रों ने पाया है कि टॉर्क स्तरों पर नज़र रखने से इन अधिकांश समस्याओं को बड़ी परेशानी बनने से पहले रोका जा सकता है। छोटे संचालन के लिए विशेष रूप से, इस प्रकार की रोकथाम रखरखाव से अप्रत्याशित खराबी और उत्पादन हानि से बचकर लंबे समय में पैसे बचाती है।

इंस्टॉलेशन कारक: स्पेस की सीमा और माउंटिंग

स्थानिक सीमाओं का मूल्यांकन

रिड्यूसर मोटर्स के चयन और स्थापना करते समय, उपलब्ध जगह की जांच करना बहुत महत्वपूर्ण है ताकि सब कुछ वहां मौजूद अन्य चीजों के साथ ठीक से फिट हो सके। मोटर को कहां लगाना है, इसकी सटीक जांच करने से सुनिश्चित होता है कि स्थापित करने के बाद वह सही ढंग से काम करे। खरीदने से पहले विनिर्देशों की जांच कर लेने से बाद में समस्याओं से बचा जा सकता है, जब भाग ठीक से मेल नहीं खाते और मरम्मत करनी पड़ती है। जगह की समस्याएं अक्सर यह तय करती हैं कि किस प्रकार की मोटर का चयन किया जाए, जिससे इंजीनियरों को डिज़ाइन और वास्तविक स्थापना कार्य कैसे करना है, इस दृष्टिकोण को आकार देता है। संकुचित गियर मोटर्स ज्यादातर स्थानों पर ठीक रहती हैं क्योंकि वे कम जगह लेती हैं और फिर भी काम की पूर्ति करती हैं, जिससे अधिकांश तकनीशियनों के लिए स्थापना सुचारु रूप से हो जाती है।

शाफ्ट संरेखण और कॉन्फिगरेशन की चुनौतियां

सही शॉफ्ट संरेखण प्राप्त करना इस बात पर निर्भर करता है कि मशीनरी के माध्यम से गति कितनी अच्छी तरह से स्थानांतरित होती है और घटकों के पहनावे को कम किया जाता है। जब चीजें संरेखित नहीं होती हैं, तो हमें समस्याएं दिखाई देने लगती हैं, जैसे कम दक्षता से लेकर अधिक बिजली के बिल तक और यहां तक कि मोटर्स का अकाल मृत्यु भी। अधिकांश अनुभवी तकनीशियन किसी भी व्यक्ति को बताएंगे कि अच्छे संरेखण उपकरणों में निवेश करना और नियमित रखरखाव अनुसूचियों का पालन करना समय के साथ सब कुछ सुचारु रूप से चलाने में मदद करता है। और उन माउंटिंग सेटअप को भी मत भूलिए, वे वास्तव में उस विशेष की मांगों के अनुरूप होने की आवश्यकता होती है यदि हम दिन-प्रतिदिन विश्वसनीय संचालन चाहते हैं। अनुप्रयोग इन संरेखण समस्याओं को ठीक करना केवल एक अच्छी बात नहीं है, यह वास्तव में मोटर के जीवनकाल को काफी हद तक बढ़ाता है, साथ ही बाद में महंगी टूट-फूट मरम्मत पर धन बचाता है।

कम्पैक्ट सेटअप में थर्मल प्रबंधन

जब कॉम्पैक्ट सिस्टम के साथ काम किया जाता है, तो मोटर्स के ओवरहीट होने से बचने के लिए ऊष्मा के प्रबंधन का विशेष ध्यान रखना महत्वपूर्ण होता है, जो उनके प्रदर्शन और सेवा आयु को गंभीर रूप से प्रभावित कर सकता है। अच्छे थर्मल प्रबंधन की शुरुआत घटकों की व्यवस्था के स्थान और सिस्टम डिज़ाइन में उपयोग की जाने वाली ऊष्मा अपव्यय विधियों से होती है। अध्ययनों से पता चलता है कि मोटर्स को उनके इष्टतम संचालन तापमान पर रखने से अप्रत्याशित खराबी को रोकने में मदद मिलती है और वास्तव में क्षेत्र में उनकी सेवा आयु बढ़ जाती है। विशेष रूप से रिड्यूसर मोटर्स के लिए, सीमित स्थान उपलब्ध होने पर हीट सिंक्स या छोटे पंखों जैसी शीतलन विशेषताओं को जोड़ना बहुत महत्वपूर्ण होता है। सही शीतलन दृष्टिकोण इन मोटर्स को स्वीकार्य तापमान सीमाओं के भीतर सुरक्षित रूप से चलाता रहता है, जिसका अर्थ है बेहतर दैनिक विश्वसनीयता और अंततः समय के साथ धन की बचत, भले ही प्रारंभिक निवेश लागतें अधिक हों।

सामान्य प्रश्न अनुभाग

रिड्यूसर मोटर क्या हैं और क्यों ये यांत्रिक प्रणालियों में महत्वपूर्ण हैं?

रिड्यूसर मोटर प्रतिसाद और टोक़्यू को सटीक गियर अनुपात के माध्यम से बदलने वाले घटक हैं, जो यांत्रिक प्रणालियों में कुशलता और प्रदर्शन में सुधार करते हैं। ये मशीनों के भीतर उत्पादकता को बढ़ाने और स्थिरता को कम करने के लिए महत्वपूर्ण हैं।

गियर अनुपात में रिड्यूसर मोटर के प्रदर्शन पर क्या प्रभाव पड़ता है?

गियर अनुपात यह निर्धारित करते हैं कि रिड्यूसर मोटर कैसे गति और टोक़्यू को समायोजित करते हैं, इससे उनकी क्षमता को विशिष्ट कार्यों और भारों को संभालने में सीधा प्रभाव पड़ता है। सही गियर अनुपात कुशलता में महत्वपूर्ण बढ़ोतरी कर सकता है और विविध परिस्थितियों के तहत मोटर की आयु बढ़ा सकता है।

एक मोटर के लिए उपयुक्त गति अनुपात का चयन करते समय क्या ध्यान में रखना चाहिए?

सही गति अनुपात का चयन अपेक्षित संचालन परिस्थितियों की गणना, भार आवश्यकताओं का मूल्यांकन और मोटर के संचालन की परिस्थितियों का अनुमान लगाना शामिल है। यह अधिकतम प्रदर्शन और ऊर्जा संरक्षण को सुनिश्चित करने में मदद करता है।

बिजली की आवश्यकताओं और मोटर संगतता का मूल्यांकन करना क्यों महत्वपूर्ण है?

बिजली की आवश्यकताओं का मूल्यांकन करना और मौजूदा प्रणालियों के साथ संगतता का यकीन करना अप्रभावीता, अधिक ऊष्मा उत्पादन, और अधिक ऊर्जा खपत से बचने के लिए आवश्यक है, जो प्रणाली की उम्र कम कर सकती है।

रिड्यूसर मोटर में शाफ्ट संरेखण से संबंधित क्या चुनौतियाँ हैं?

गलत शाफ्ट संरेखण अप्रभावीता, बढ़ी हुई ऊर्जा खपत, और संभावित मोटर विफलताओं का कारण बन सकता है। संरेखण उपकरणों का उपयोग करना और नियमित जाँचें करना मदद करता है मोटर की जिंदगी बढ़ाने और प्रदर्शन को अधिकतम करने में।

विषय सूची

- रिड्यूसर मोटर्स को समझें: मुख्य कार्य और महत्व

- अधिकतम प्रदर्शन के लिए महत्वपूर्ण चयन पैरामीटर

- रिडিযूसर मोटर के प्रकार और उनके अनुप्रयोग

- बोझ क्षमता और ड्यूटी साइकिल की मांगों को मिलाना

- इंस्टॉलेशन कारक: स्पेस की सीमा और माउंटिंग

-

सामान्य प्रश्न अनुभाग

- रिड्यूसर मोटर क्या हैं और क्यों ये यांत्रिक प्रणालियों में महत्वपूर्ण हैं?

- गियर अनुपात में रिड्यूसर मोटर के प्रदर्शन पर क्या प्रभाव पड़ता है?

- एक मोटर के लिए उपयुक्त गति अनुपात का चयन करते समय क्या ध्यान में रखना चाहिए?

- बिजली की आवश्यकताओं और मोटर संगतता का मूल्यांकन करना क्यों महत्वपूर्ण है?

- रिड्यूसर मोटर में शाफ्ट संरेखण से संबंधित क्या चुनौतियाँ हैं?