Rozumienie reduktorów motorowych: Podstawowe funkcje i znaczenie

Podstawowa rola w systemach mechanicznych

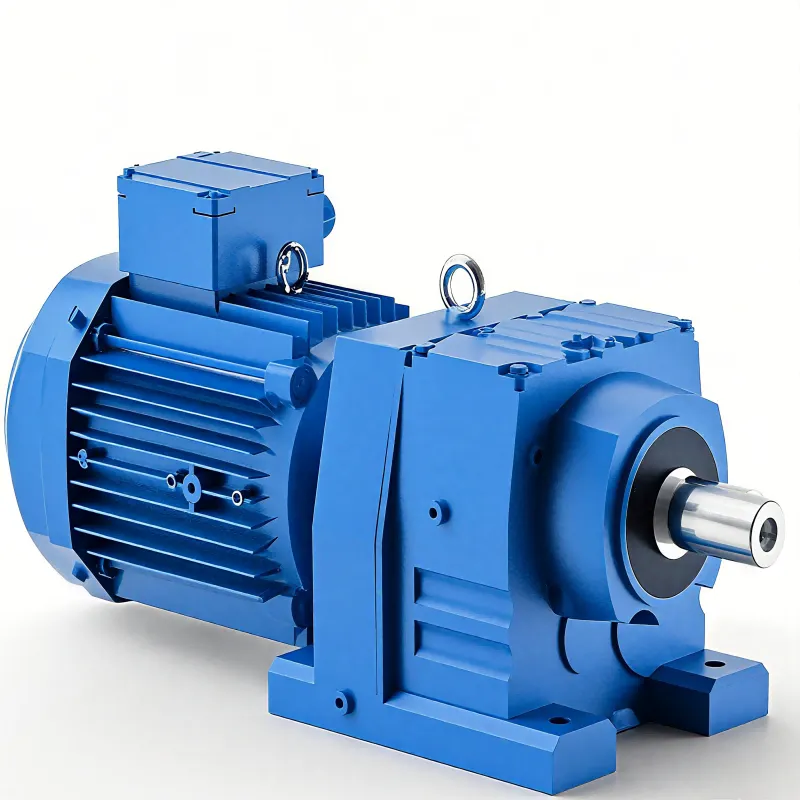

Silniki reduktorowe odgrywają bardzo ważną rolę w różnych rodzajach systemów mechanicznych. Pomagają zwiększyć efektywność i wydajność, kontrolując prędkość poruszania się elementów oraz rodzaj generowanej siły. Te silniki są niemalże nieodzowne w każdej instalacji przemysłowej, gdzie istotne jest dokładne dopasowanie parametrów. Większość fabryk nie funkcjonowałaby sprawnie bez ich udziału w utrzymaniu całości. Zgodnie z niektórymi danymi branżowymi, prawidłowo zamontowane silniki reduktorowe mogą rzeczywiście poprawić pracę maszyn o około 30%, dlatego inżynierowie poświęcają im tak dużą uwagę. Patrząc na typowe urządzenia wokół nas, te silniki pełnią w zasadzie rolę połączenia między źródłem zasilania maszyny a jej bezpośrednimi elementami roboczymi. To połączenie zapewnia sprawną pracę każdego dnia oraz pomaga zapobiegać niepotrzebnemu zużyciu na przestrzeni czasu.

Jak silniki redukcyjne modyfikują moment obrotowy i prędkość

Silniki reduktorowe dostosowują prędkość i moment obrotowy wyjściowy poprzez zmianę przełożeń, umożliwiając maszynom lepsze funkcjonowanie w różnych zastosowaniach. Inżynierowie muszą zrozumieć, jak zmiany momentu i prędkości współdziałają ze sobą podczas projektowania systemów, które radzą sobie z różnorodnymi obciążeniami i prędkościami. Gdy przełożenia są prawidłowo dobrane, silniki pracują bardziej efektywnie i mają dłuższą trwałość, zwłaszcza przy zmiennych warunkach pracy. Główne parametry do śledzenia to stosunek redukcji, ponieważ ma on bezpośredni wpływ na moc wyjściową silnika oraz na ogólną wydajność. Dzięki odpowiedniemu doborowi, silniki te umożliwiają płynną pracę zarówno w przypadku podstawowego sprzętu, jak i skomplikowanych systemów fabrycznych wymagających precyzyjnie dobranego momentu obrotowego i kontrolowanej prędkości.

Kluczowe Parametry Wyboru dla Optymalnej Wydajności

Wymagania Mocy i Zgodność Silnika

Podczas doboru silników reduktorowych do zastosowań mechanicznych pierwszym krokiem jest sprawdzenie wymagań dotyczących mocy. Ten proces polega w zasadzie na upewnieniu się, że parametry mocy silnika dobrze współdziałają z istniejącymi systemami sterowania, aby wszystko działało niezawodnie. Poprawne dobranie parametrów ma znaczenie, ponieważ niezgodność wartości mocy prowadzi do problemów w przyszłości. Silniki, które nie są odpowiednio dobrane, często pracują mniej wydajnie i szybciej się zużywają, o czym wiele producentów silników chętnie informuje zainteresowanych. Warto przyjrzeć się sytuacji, gdy ktoś zainstaluje silnik o zbyt niskiej mocy – zazwyczaj się przegrzewa lub niepotrzebnie zużywa dużo energii. Zanim zdecyduje się na konkretny silnik, inteligentni technicy zawsze sprawdzają trzy podstawowe kwestie: skąd pochodzi zasilanie, jakie napięcie jest potrzebne i ile energii rzeczywiście zużywa cały system. Taka wstępna ocena pomaga utrzymać płynny przebieg operacji i wydłużyć okres eksploatacji urządzeń w różnych środowiskach przemysłowych.

Współczynnik prędkości i zagadnienia dotyczące efektywności

W przypadku silników reduktorowych stosunek prędkości odgrywa kluczową rolę w określaniu ich skuteczności działania, zwłaszcza przy różnych rodzajach obciążeń. Dobranie właściwego stosunku znacząco wpływa na moment obrotowy, co pomaga urządzeniom oszczędzać energię podczas pracy. Weźmy na przykład zakłady produkcyjne, gdzie nawet niewielka poprawa, taka jak 10-procentowa efektywność, może przekładać się na rzeczywiste oszczędności finansowe w dłuższym horyzoncie czasowym, szczególnie w przypadku maszyn pracujących bez przerwy przez całe zmiany. Dobierając odpowiedni stosunek prędkości, nie należy się jednak spieszyć. Wymaga to analizy rodzaju obciążeń, z jakimi system boryka się na co dzień. Inżynierowie muszą określić nie tylko aktualne potrzeby maszyny, ale także przewidywać przyszłe warunki pracy, aby silnik nie tracił energii lub nie ulegał przeciążeniu w nieprzewidzianych sytuacjach.

Gęstość momentu obrotowego i granice działania

Gęstość momentu obrotowego wskazuje, jaką siłę obrotową silnik może wygenerować w porównaniu do jego wymiarów fizycznych i masy. Ten parametr odgrywa dużą rolę w ocenie, czy silnik będzie dobrze sprawował się w konkretnym zadaniu. Projektanci systemów muszą znać dokładne możliwości silnika, zanim dojdzie do jego przeciążenia i problemów. Przeciążanie silników prowadzi do szybszych uszkodzeń i wyższych kosztów napraw w przyszłości. Większość branż ustaliła wytyczne dotyczące dopuszczalnych poziomów momentu obrotowego dla różnych typów urządzeń przy doborze silników i planowaniu ich wymiany. Analiza danych z praktyki wskazuje, że przestrzeganie zalecanych zakresów znacznie wydłuża żywotność silników i obniża koszty energii elektrycznej. Dla osób zarządzających maszynami na co dzień, prawidłowy dobór ma kluczowe znaczenie zarówno dla oszczędności, jak i dla sprawnego przebiegu pracy.

Orientacja wału: Koaksjalna, Równoległa lub Prostopadła

Położenie wału w silniku reduktorowym ma duże znaczenie przy dopasowywaniu do różnych układów mechanicznych. Poprawne ustawienie zmniejsza obciążenie elementów wewnętrznych i ułatwia montaż. Układy współosiowe dobrze sprawdzają się w ciasnych przestrzeniach, ponieważ zajmują mniej miejsca, natomiast konfiguracje równoległe dają inżynierom więcej możliwości funkcjonalnego dopasowania elementów. Projektując każdy układ mechaniczny, warto zastanowić się nad położeniem wału, aby osiągnąć lepszą wydajność ogólnie. Odpowiednia równoległość to także rozsądny wybór pod względem efektywności i trwałości. Źle wyjustowane silniki ulegają szybszemu zużyciu, ponieważ ich ruchome części są narażone na dodatkowe naprężenia w czasie pracy, co skraca ich żywotność i zwiększa konieczność wcześniejszej wymiany.

Rodzaje silników redukcyjnych i ich zastosowania

Silniki planetarne: precyzyjna moc obrotowa

Gdy aplikacje wymagają zarówno dużego momentu obrotowego, jak i kompaktowej konstrukcji, silniki z przekładnią planetarną naprawdę się wyróżniają. Te silniki dostarczają dużą moc w niewielkiej przestrzeni, zachowując jednocześnie precyzyjną kontrolę, co czyni je idealnym wyborem w sytuacjach, gdzie każdy cal ma znaczenie. Od przemysłowych robotów na hali produkcyjnej po taśmy transportowe w liniach pakujących – producenci polegają na tych silnikach, ponieważ lepiej sprawdzają się w ograniczonej przestrzeni. Niektóre badania wykazują, że te systemy osiągają sprawność powyżej 90% w praktyce, co oznacza, że firmy oszczędzają na rachunkach za energię w dłuższej perspektywie czasowej. Co je wyróżnia? Specjalne ułożenie przekładni równomiernie rozkłada obciążenie na wiele punktów, dzięki czemu komponenty nie ulegają tak szybkiemu zużyciu. Ten aspekt konstrukcyjny staje się szczególnie istotny w trudnych warunkach eksploatacyjnych, gdzie niezawodność ma kluczowe znaczenie.

Silniki biegunkowe śrubowe: Bezpieczeństwo i rozwiązania o wysokim współczynniku zmiany prędkości

Silniki do przekładni ślimakowych wyróżniają się, gdy chodzi o dostarczanie rozwiązań o wysokim przełożeniu, ponieważ są wyposażone w przydatną funkcję samohamowności, która zapewnia bezpieczeństwo w różnych zastosowaniach. To, co czyni te silniki tak przydatnymi, to ich zdolność do zapobiegania ruchowi zwrotnemu, co oznacza, że doskonale sprawdzają się w miejscach takich jak windy i taśmy transportowe, gdzie zabezpieczenie wszystkiego ma pierwszorzędne znaczenie. Inżynierowie wielokrotnie przekonywali się, jak dobrze te przekładnie radzą sobie z dużymi redukcjami przełożeń – coś szczególnie ważnego dla dużych maszyn przemysłowych, które wymagają skutecznego przekazywania mocy. Gdy firmy wybierają silniki przekładni ślimakowych zamiast innych opcji, zwykle sprowadza się to do chęci uzyskania dodatkowego poziomu ochrony przed wypadkami, zwłaszcza w sytuacjach, gdy istnieje ryzyko związane z niekontrolowanym obciążeniem.

Silniki zębatkowe: kosztowna transmisja mocy

Oglądając opcje transmisji mocy, silniki z przekładnią zazębiającą wyróżniają się jako solidny wybór ze względu na swoją prostotę i przyjazność dla budżetu. Ich podstawowa konstrukcja oznacza, że te silniki zazwyczaj działają niezawodnie przy minimalnym konserwacji, co czyni je odpowiednimi dla różnych zastosowań przemysłowych. Spojrzenie na liczby pokazuje, że firmy mogą zaoszczędzić pieniądze na starcie wybierając systemy przekładni zazębiających, które ponadto charakteryzują się dużą trwałością przed koniecznością wymiany. Wiele maszyn o średnim obciążeniu faktycznie polega na tych silnikach, ponieważ skutecznie wykonują one swoje zadanie bez dodatkowych funkcji bardziej skomplikowanych alternatyw. Menedżerowie fabryk doceniają, jak łatwe jest utrzymanie tych systemów w czasie, umożliwiając płynne przebieganie operacji bez nieoczekiwanych przestojów czy kosztownych napraw w przyszłości.

Silniki z przekładnią stożkową: kątowy przekaz mocy

Zębate przekładnie stożkowe działają naprawdę dobrze, gdy trzeba przenieść moc pod kątem, co czyni je niemal nieodzownymi wszędzie tam, gdzie zmienia się kierunek przekazywania mocy. Spójrz na dowolnej hali fabrycznej – zębatki te pojawiają się wszędzie, zwłaszcza w systemach taśmociągów i w samochodach, gdzie liczy się ograniczona przestrzeń i istotne są kąty. Według relacji inżynierów, zębatki te znacznie podnoszą efektywność przy przekazywaniu ruchu pomiędzy różnymi kierunkami. Dobierając przekładnię stożkową, dopasowanie jej do konkretnego zadania jest niezwykle ważne. Uzyskanie tego oznacza większą dokładność i systemy działające bez zarzutu, co w dłuższej perspektywie pozwala zaoszczędzić czas i pieniądze dla większości operacji.

Dopasowywanie pojemności obciążeniowej i wymagań cyklu pracy

Obliczanie wymagań dotyczących momentu obrotowego w pracy

Uzyskanie właściwych wartości momentu obrotowego dla operacji odgrywa ogromną rolę, jeśli chcemy, aby silniki rzeczywiście radziły sobie z tym, do czego są przeznaczone w praktycznych zastosowaniach. Przy ustalaniu wymagań dotyczących momentu obrotowego inżynierowie muszą wziąć pod uwagę kilka czynników, w tym wielkość obciążenia, szybkość przyspieszania oraz uwzględnić wszelkie drobne straty energii wynikające z tarcia w poszczególnych elementach systemu. Większość podręczników technicznych zaleca podstawianie tych wartości do standardowych wzorów, aby uzyskać realistyczne wyobrażenie o tym, jak dobrze silnik będzie działał w warunkach rzeczywistych. Dokładne odnotowywanie specyfikacji momentu obrotowego pomaga uniknąć problemów w przyszłości, gdy pojawią się nieoczekiwane trudności, a także przedłuża żywotność silników, zanim zajdzie potrzeba ich wymiany lub naprawy. Proste wpisy w dzienniku serwisowym dziś pozwalają zaoszczędzić czas i pieniądze jutro, gdy konieczna staje się diagnostyka, zamiast reagować dopiero po wystąpieniu awarii.

Scenariusze ciągłe kontra przerywane

Znajomość momentu, kiedy należy wybrać silnik do pracy ciągłej w porównaniu z pracą okresową, ma kluczowe znaczenie, aby dobrze wykonać zadanie. Silniki pracujące w sposób ciągły muszą radzić sobie z ustalonymi obciążeniami przez cały dzień, dlatego szczególnie ważne jest zwracanie uwagi na problemy związane z nagromadzeniem ciepła. Sytuacja wygląda inaczej w przypadku silników do pracy okresowej – często napotykają one zmienne obciążenia w trakcie cyklu pracy, co oznacza, że dokładne analizowanie specyfikacji staje się konieczne. Dane branżowe wskazują, że wybór niewłaściwego typu cyklu pracy skutkuje wieloma problemami w przyszłości, zarówno pod względem spadku wydajności, jak i skrócenia okresu eksploatacji silnika. Gdy inżynierowie poprawnie dobiorą silniki do odpowiednich cykli pracy, osiągają one gładki przebieg procesów w maszynach, oszczędzają koszty wymiany oraz przedłużają ogólny czas użytkowania urządzeń zanim zajdzie potrzeba ich naprawy lub wymiany.

Wpływ przegrzania na długość życia silnika

Zbyt duży obciążenie silników reduktorowych to jeden z problemów, które dość często pojawiają się w środowiskach przemysłowych. Kiedy te silniki pracują z zbyt dużym momentem obrotowym, zaczynają się z wewnątrz niszczyć, ogrzewać i ostatecznie wymagają kosztownego naprawienia lub wymiany części. Niektóre dane z terenu wskazują, że silniki pracujące poza swoimi parametrami projektowymi mogą działać nawet o połowę krócej, niż powinny. Dlatego tak ważne jest przestrzeganie wytycznych producenta pod względem trwałości urządzeń. W tym miejscu sensowne jest zastosowanie czujników momentu obrotowego. Wiele zakładów produkcyjnych zauważyło, że monitorowanie poziomu momentu obrotowego pomaga zapobiec większości tych problemów zanim staną się poważnymi kłopotami. Szczególnie dla mniejszych operacji tego typu utrzymanie zapobiegawcze pozwala zaoszczędzić pieniądze na dłuższą metę, unikając nieoczekiwanych przestojów i strat produkcyjnych.

Czynniki instalacyjne: Ograniczenia przestrzenne i sposoby montażu

Ocena ograniczeń przestrzennych

Podczas dobierania i konfigurowania silników reduktorowych sprawdzenie dostępnej przestrzeni ma kluczowe znaczenie, aby wszystko prawidłowo pasowało do istniejącej konstrukcji. Analiza dokładnego miejsca montażu silnika zapewnia jego poprawne działanie po zainstalowaniu w ograniczonych warunkach przestrzennych. Przejrzenie specyfikacji przed zakupem pozwala uniknąć problemów w przyszłości, gdy elementy nie będą się zgrywać. Ograniczenia przestrzenne często decydują o wyborze typu silnika, wpływając na podejście inżynierów do projektowania i faktycznych prac montażowych. Kompaktowe silniki z przekładniami najlepiej sprawdzają się w ciasnych miejscach, ponieważ zajmują mniej miejsca, jednocześnie realizując swoje funkcje, co ułatwia ogólnie instalację dla większości techników pracujących na placu budowy.

Wyposażenie i wyzwania związane z wyrównaniem wałków

Dobrze wykonane wyważenie wału ma ogromne znaczenie dla skuteczności przekazywania ruchu przez maszyny oraz zmniejszenia zużycia elementów. Kiedy coś jest niewyważone, zaczynają się pojawiać problemy, od zmniejszenia wydajności, przez wyższe rachunki za energię, aż po przedwczesne wychodzenie z użycia silników. Każdy doświadczony technik powie, że inwestycja w dobre narzędzia do wyważania oraz przestrzeganie regularnych harmonogramów konserwacji pozwala na stabilną pracę przez długi czas. Również konstrukcje montażowe są ważne – muszą odpowiadać wymaganiom konkretnego urządzenia, jeśli chcemy uzyskiwać niezawodną pracę z dnia na dzień. zastosowanie naprawienie problemów z wyważaniem to nie tylko miłe udogodnienie – znacząco wydłuża żywotność silników i pozwala zaoszczędzić pieniądze na kosztownych naprawach awaryjnych w przyszłości.

Zarządzanie cieplne w kompaktowych układach

Podczas pracy z kompaktowymi systemami zarządzanie ciepłem staje się bardzo ważne, aby zapobiec przegrzewaniu silników, co może poważnie wpłynąć na ich wydajność i trwałość. Dobre zarządzanie termiczne zaczyna się od rozmieszczenia komponentów oraz od metod odprowadzania ciepła stosowanych w całym procesie projektowania systemu. Badania wykazują, że utrzymywanie silników w optymalnej temperaturze pracy pomaga uniknąć nieoczekiwanych awarii i faktycznie wydłuża ich czas użytkowania w terenie. W przypadku silników z reduktorem szczególnie istotne jest stosowanie rozwiązań chłodzących, takich jak radiatory czy małe wentylatory, jeśli przestrzeń jest ograniczona. Odpowiednie podejście chłodnicze pozwala tym silnikom działać bezpiecznie w dopuszczalnych granicach temperatury, co przekłada się na lepszą niezawodność na co dzień i ostatecznie prowadzi do oszczędności finansowych w dłuższej perspektywie, mimo początkowych kosztów inwestycyjnych.

Sekcja FAQ

Co to są silniki redukcyjne i czemu są one ważne w systemach mechanicznych?

Silniki redukcyjne to elementy, które modyfikują prędkość i moment obrotowy za pomocą dokładnych współczynników przekładni, aby zwiększyć wydajność i wydajność w układach mechanicznych. Są kluczowe dla optymalizacji produktywności i zmniejszenia zużycia maszyn.

Jak wpływa przekładnia zębowa w silnikach redukcyjnych na ich wydajność?

Przekładnie zębowe określają, jak silniki redukcyjne dostosowują prędkość i moment obrotowy, bezpośrednio wpływając na ich zdolność do obsługi konkretnych zadań i obciążeń. Prawidłowa przekładnia zębowa może znacząco zwiększyć efektywność i przedłużyć żywotność silnika, zwłaszcza w warunkach zmieniających się.

Co należy uwzględnić podczas wybierania odpowiedniego współczynnika prędkości dla silnika?

Wybór odpowiedniego współczynnika prędkości obejmuje obliczanie oczekiwanych warunków eksploatacyjnych, ocenę wymagań obciążeniowych oraz prognozowanie scenariuszy, w których będzie działał silnik. To pozwala zapewnić optymalną wydajność i oszczędność energii.

Dlaczego jest ważne ocenianie wymagań energetycznych i zgodności silników?

Ocena wymagań energetycznych oraz zapewnienie zgodności z istniejącymi systemami jest kluczowe, aby uniknąć nieskuteczności, przegrzania się i nadmiernego zużycia energii, co może skrócić żywotność systemu.

Jakie są wyzwania związane z wyrównaniem wału w silnikach redukcyjnych?

Niewłaściwe wyrównanie wału może prowadzić do nieskuteczności, zwiększonego zużycia energii i potencjalnych awarii silnika. Używanie narzędzi do wyrównania i regularne kontrolowanie pomagają przedłużyć żywotność silnika i zoptymalizować jego wydajność.

Spis treści

- Rozumienie reduktorów motorowych: Podstawowe funkcje i znaczenie

- Kluczowe Parametry Wyboru dla Optymalnej Wydajności

- Rodzaje silników redukcyjnych i ich zastosowania

- Dopasowywanie pojemności obciążeniowej i wymagań cyklu pracy

- Czynniki instalacyjne: Ograniczenia przestrzenne i sposoby montażu

-

Sekcja FAQ

- Co to są silniki redukcyjne i czemu są one ważne w systemach mechanicznych?

- Jak wpływa przekładnia zębowa w silnikach redukcyjnych na ich wydajność?

- Co należy uwzględnić podczas wybierania odpowiedniego współczynnika prędkości dla silnika?

- Dlaczego jest ważne ocenianie wymagań energetycznych i zgodności silników?

- Jakie są wyzwania związane z wyrównaniem wału w silnikach redukcyjnych?