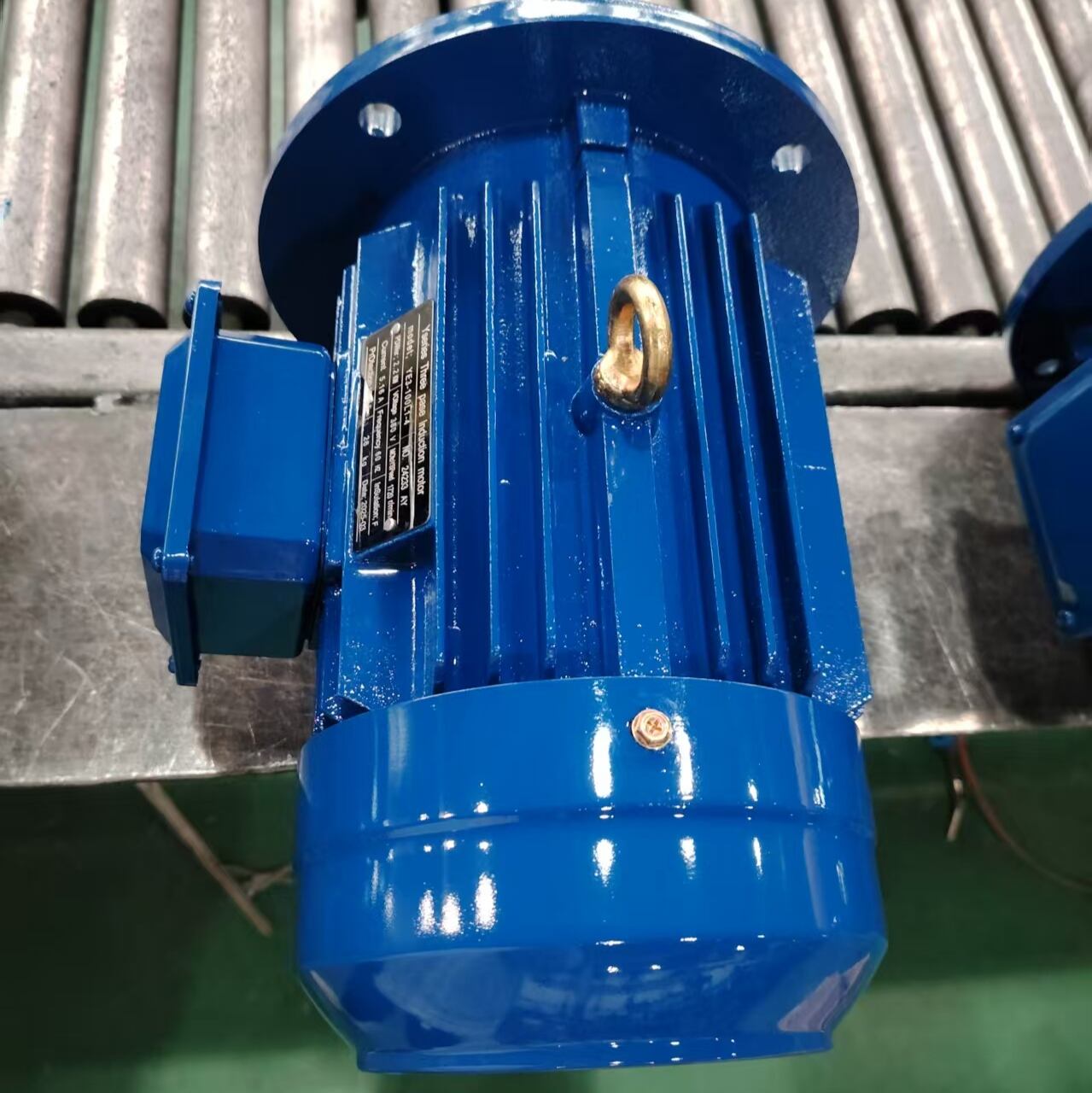

electric motor squirrel cage

The electric motor squirrel cage, also known as a squirrel cage rotor, represents a fundamental component in induction motors that has revolutionized industrial operations. This ingenious design consists of a cylindrical core made up of steel laminations with aluminum or copper bars embedded longitudinally around its periphery. These bars are connected at both ends by conductive rings, creating a structure that resembles a hamster exercise wheel, hence its distinctive name. When exposed to a rotating magnetic field created by the stator, the squirrel cage induces electrical currents that generate their own magnetic field, resulting in rotational motion. This simple yet effective design eliminates the need for brushes or complicated wiring, making it exceptionally reliable and maintenance-friendly. The squirrel cage construction allows for efficient power transfer and smooth operation across various speed ranges, making it ideal for numerous applications from industrial machinery to household appliances. Its robust construction can withstand harsh operating conditions while maintaining consistent performance, and its design allows for cost-effective manufacturing without compromising on durability or efficiency.