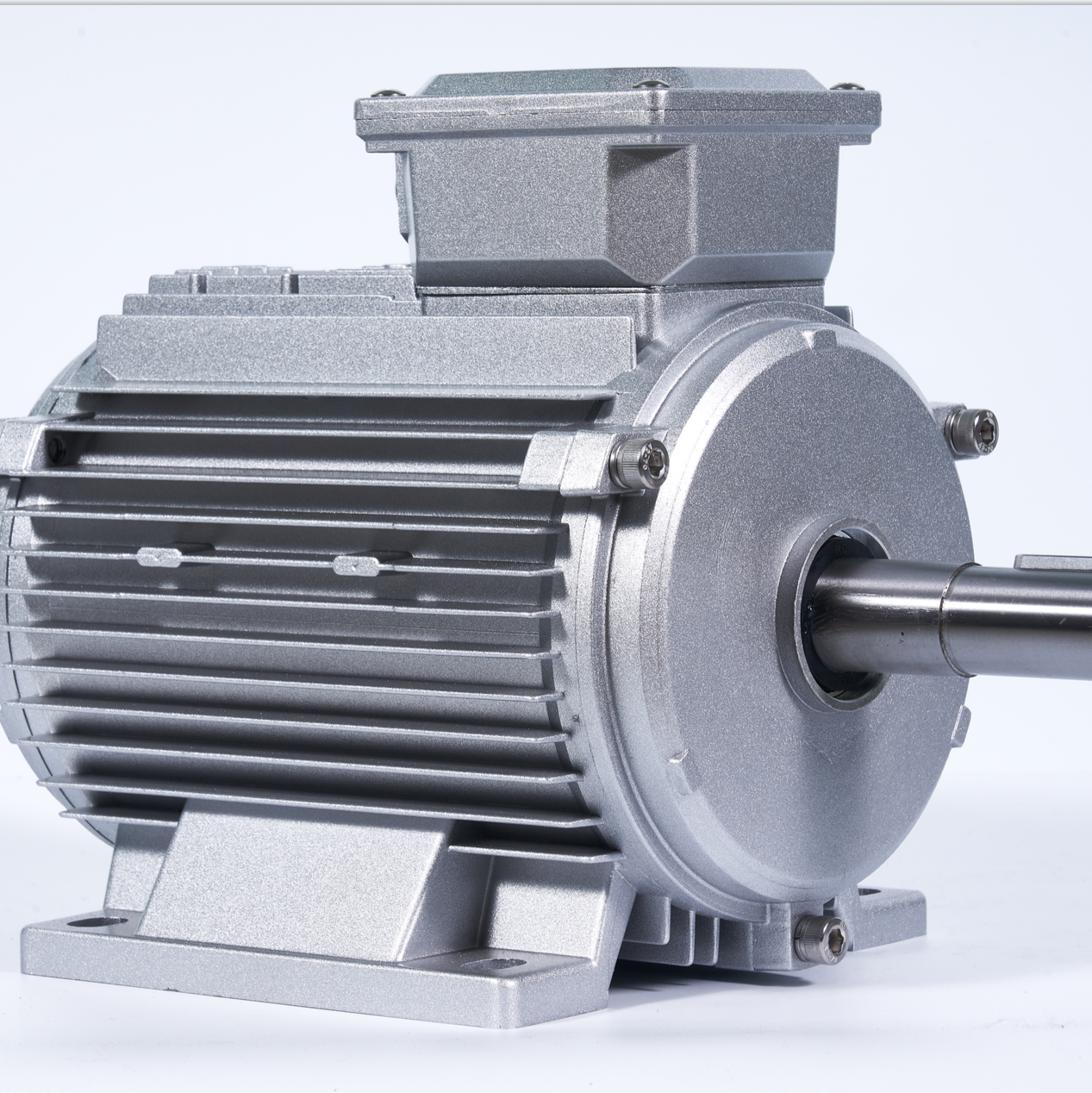

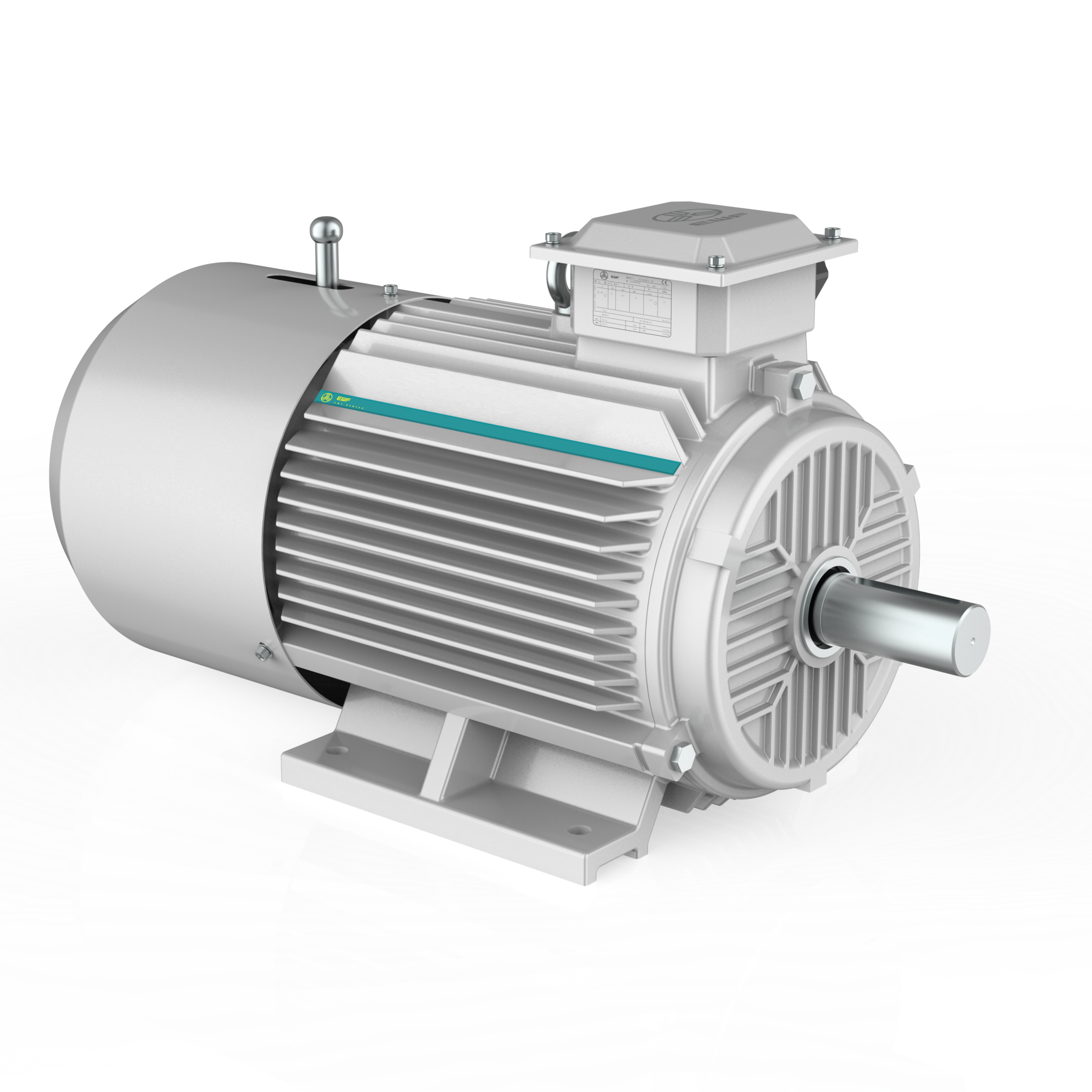

cage rotor

A cage rotor is a critical component in electric motors, particularly in induction motors, characterized by its distinctive construction of conducting bars embedded in a cylindrical core. This fundamental design consists of aluminum or copper bars arranged in a cylindrical pattern, connected at both ends by conducting rings, creating a structure resembling a squirrel cage. The rotor operates based on electromagnetic induction principles, where the rotating magnetic field from the stator induces currents in the cage bars, generating a secondary magnetic field. This interaction produces the torque necessary for motor operation. The cage rotor's design excels in robustness and reliability, making it ideal for various industrial applications. Its construction allows for efficient heat dissipation, minimal maintenance requirements, and consistent performance across different operating conditions. The rotor's simple yet effective design enables it to withstand high starting torques and operate efficiently at various speeds. Modern manufacturing techniques have further enhanced the cage rotor's capabilities, incorporating advanced materials and precise engineering to optimize performance and energy efficiency. These rotors are widely used in applications ranging from industrial machinery to HVAC systems, proving their versatility and reliability in diverse operating environments.