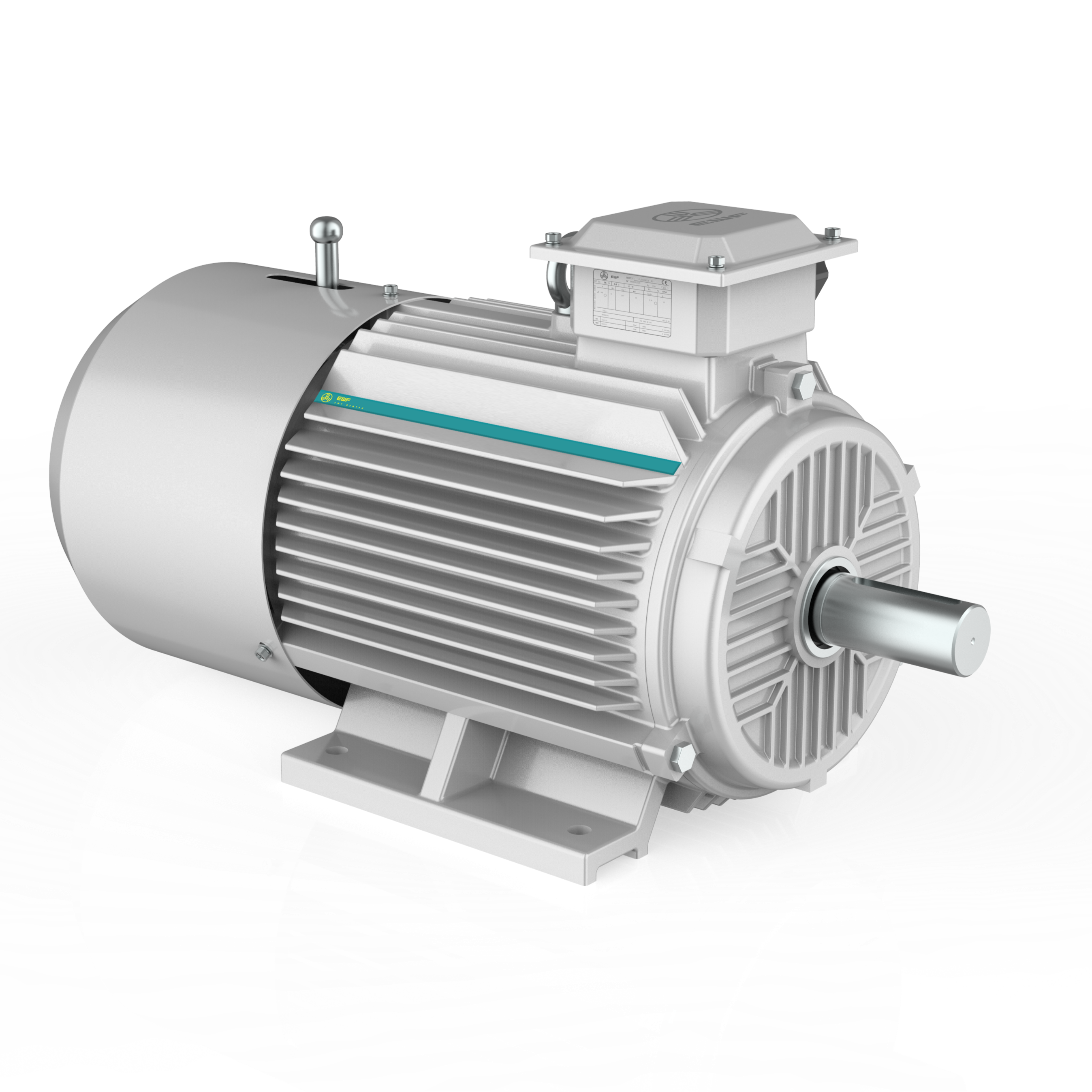

cage rotor induction motor

The cage rotor induction motor stands as a cornerstone of industrial power systems, characterized by its robust and efficient design. At its core, this motor features a distinctive squirrel cage rotor construction, comprising aluminum or copper bars connected by end rings. This ingenious design allows for seamless electromagnetic induction between the stator's rotating magnetic field and the rotor, generating the torque necessary for operation. The motor operates on the principle of electromagnetic induction, where the rotating magnetic field in the stator induces current in the rotor bars, creating a magnetic field that interacts with the stator field to produce rotation. The cage rotor design eliminates the need for electrical connections to the rotor, resulting in exceptional reliability and minimal maintenance requirements. These motors typically operate at fixed speeds determined by the power supply frequency and the number of poles, though modern variable frequency drives enable speed control. Common applications include industrial machinery, pumps, fans, compressors, and conveyor systems, where their combination of reliability, efficiency, and cost-effectiveness makes them indispensable.