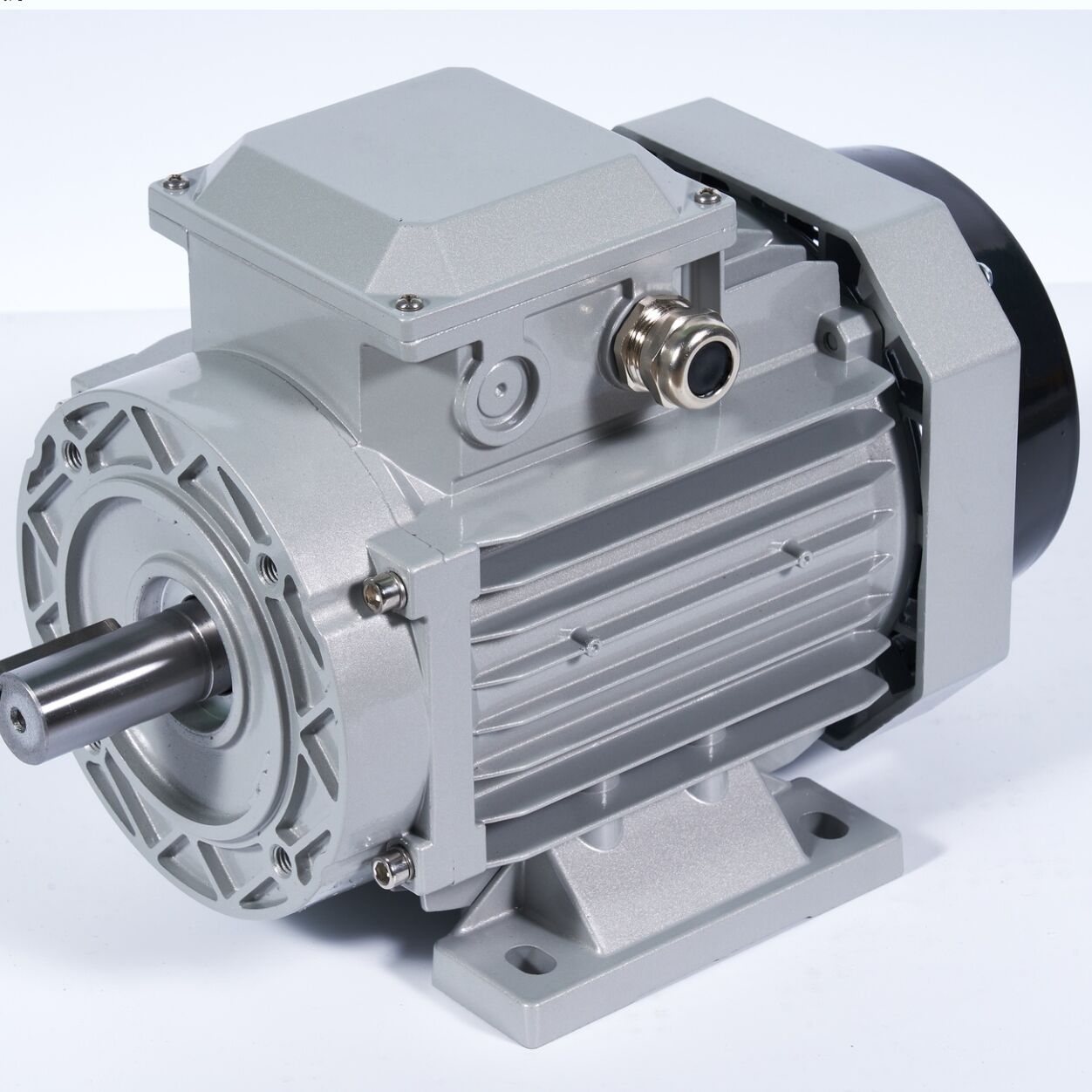

squirrel cage rotor induction motor

The squirrel cage rotor induction motor stands as one of the most widely used and reliable electric motors in industrial applications. This motor derives its name from its distinctive rotor construction, which resembles a squirrel's exercise cage. The rotor consists of aluminum or copper bars embedded in a cylindrical laminated core, connected at both ends by shorting rings, creating a cage-like structure. When powered, the stator's rotating magnetic field induces current in these bars, generating electromagnetic forces that cause the rotor to spin. This simple yet effective design eliminates the need for brushes or complex winding arrangements, resulting in exceptional reliability and minimal maintenance requirements. The motor operates on the principle of electromagnetic induction, where the speed of rotation depends on the frequency of the power supply and the number of poles in the stator winding. These motors are available in various power ratings, from fractional horsepower to several thousand horsepower, making them suitable for diverse applications ranging from household appliances to heavy industrial machinery. Their robust construction and ability to operate in challenging environments have made them the preferred choice in manufacturing, HVAC systems, pumps, compressors, and conveyor systems.