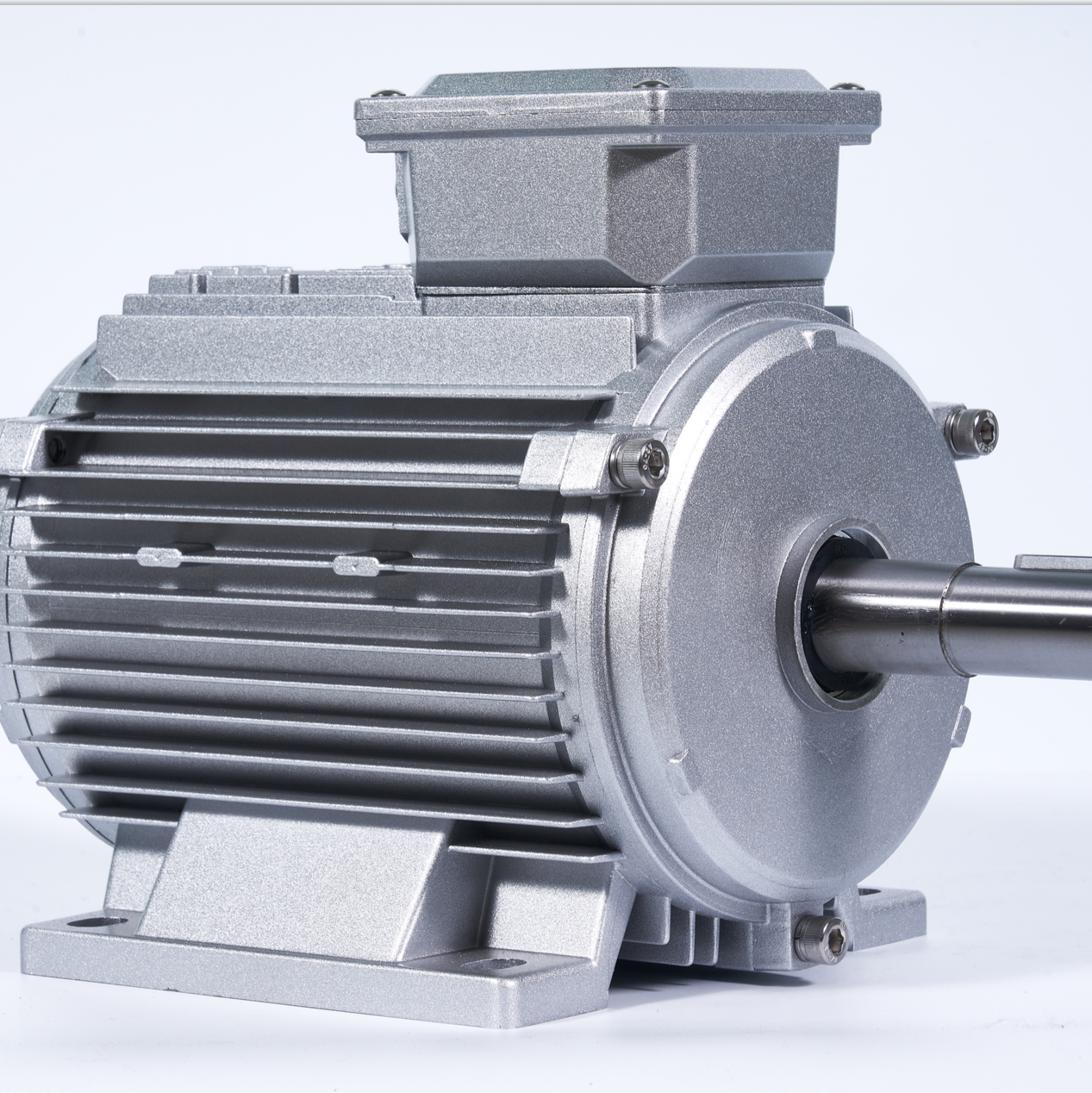

squirrel cage motor

A squirrel cage motor represents one of the most widely used and reliable types of induction motors in industrial applications. This robust electric motor derives its name from its distinctive rotor construction, which resembles a cage or drum. The rotor consists of aluminum or copper bars connected by end rings, forming a structure similar to a squirrel's exercise wheel. The motor operates on the principle of electromagnetic induction, where the rotating magnetic field created by the stator induces current in the rotor bars, generating torque. The simple yet effective design eliminates the need for brushes or complex electrical connections, making it extraordinarily reliable and maintenance-friendly. The motor's construction allows for excellent heat dissipation and provides superior mechanical strength, enabling it to withstand demanding industrial environments. These motors typically operate at fixed speeds, though modern variants can be coupled with variable frequency drives for speed control. Their applications span across numerous industries, from powering conveyor belts and pumps to driving fans and compressors. The squirrel cage motor's combination of simplicity, durability, and cost-effectiveness has made it the backbone of industrial motorization, accounting for approximately 90% of all industrial motors in use today.